- Room 1807, Unit 9, Building 2, Shangxing Commercial Street, Shangde Road, Shangxing Community, Xinqiao Subdistrict, Bao'an District, Shenzhen City, China

Aerospace & UAV

WJ Prototypes is your 3D manufacturing partner from prototype to large scale production.

Consumer Electronics

New Product Introduction Solutions for Consumer Electronics.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Automotive

New Product Introduction Solutions for Automotive

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

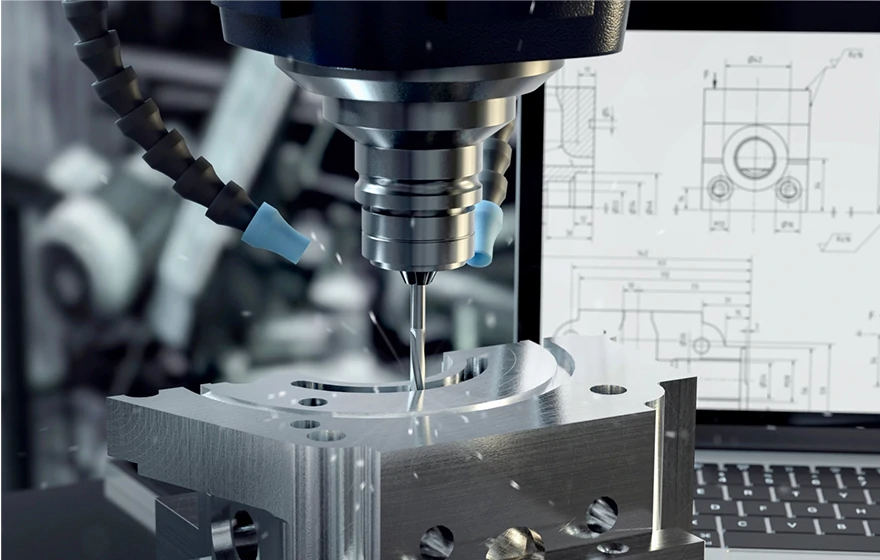

In today’s competitive educational landscape, integrating hands-on technology into curricula is essential for nurturing future innovators. CNC machining—Computer Numerical Control machining—is an advanced manufacturing technique that uses computerized controls to operate machine tools. This technology is pivotal not only in manufacturing but also in education, bridging academic theory with practical applications. By incorporating CNC machining in classrooms, institutions empower students to develop practical skills, foster innovative thought processes, and become familiar with advanced digital manufacturing systems. This article explores how CNC machining transforms education by outlining its core principles, benefits, and diverse applications, while also providing strategies for effective implementation.

Transitioning from theory to practice, CNC machining enhances student engagement and offers invaluable hands-on experience. As schools prepare students for modern industries, CNC technology supports critical thinking, attention to detail, and technical proficiency, allowing students to experiment and refine prototypes into tangible products.

CNC machining in education begins with a clear definition: using computer programs to control cutting tools that shape materials such as metal, wood, or plastic. In contemporary classrooms, this technology transforms digital designs into physical prototypes. Educators use CNC machining to improve production accuracy and simulate industrial operations, thus deepening students’ understanding of advanced technological principles.

CNC technology is centered on computer-controlled precision. Programs direct machine tools to perform tasks with repeatability and accuracy. In educational settings, CNC machining is presented as an essential tool for developing technical skills. Students learn machine language, geometric dimensioning and tolerancing, and how software like SolidWorks or Mastercam integrates digital design with physical production—a foundational skill set for careers in manufacturing and engineering.

Establishing CNC literacy is key for preparing students for Industry 4.0. Learning CNC technology bridges theoretical instruction with hands-on application. This experiential learning deepens understanding of both digital and analog manufacturing techniques while enhancing critical thinking and problem-solving skills. With CNC literacy, students are better equipped to meet the technical demands of the modern workforce.

Selecting the right CNC machine is critical in education. Common options include desktop CNC mills, CNC routers, and small-scale laser or plasma cutters. Desktop machines balance affordability with functionality and are ideal for introducing digital machining. CNC routers, capable of cutting wood and plastic, are versatile for design and prototyping, while compact laser machines enable high-precision engraving and cutting. The choice depends on safety protocols, ease of use, maintenance requirements, and overall educational goals.

Integrating CNC machining involves aligning the technology with existing subjects. In STEM classes, it complements lessons in mathematics, physics, and engineering. In art and design courses, CNC tools help create intricate sculptures and installations, merging technical precision with creative expression. Project-based modules—where students design, simulate, and manufacture prototypes—reinforce theoretical learning with tangible projects, fostering an interdisciplinary approach and sparking innovation.

We Are Happy To Help You! - Serving Clients Worldwide From China - Dedicated Project Manager.

No MOQ | Quality & Precision | Fast Turnaround | Rapid Prototypes | Low-Volume To Mass Production | Global Delivery

You can submit your designs to us through our contact us page

OR Email to info@wjprototypes.com

CNC machining in education offers several advantages, addressing both student learning outcomes and institutional goals. Its benefits include practical skill development, improved engagement, and preparation of a future workforce proficient in modern manufacturing technologies.

A primary advantage of CNC machining is the development of tangible, hands-on skills. The transition from theory to physical creation reinforces students’ technical competence and confidence. For example, designing a part on CAD software and then using a CNC mill to produce it demonstrates the full cycle of product development. This process reinforces accuracy, precision, and safety in manufacturing.

By converting digital models into real-world products, CNC machining makes abstract concepts concrete. This hands-on process enhances cognitive skills, as students troubleshoot machine errors, calibrate equipment, and adjust designs. The tangible outcomes boost retention and encourage collaborative projects that mirror real industry challenges, creating a culture of innovation and effective problem solving.

CNC machining effectively bridges the gap between classroom theory and industrial practice. Concepts such as rigid-body dynamics or material properties are difficult to visualize until they are applied practically. Observing how material properties affect tool wear or cutting efficiency reinforces classroom instruction and validates theoretical knowledge through real-world application.

Integrating CNC machining directly supports STEM career pathways by aligning academic outcomes with industry standards. Proficiency in CNC operations, CAD/CAM software, and computer programming is increasingly essential for engineering, manufacturing, and design roles. Employers value graduates with hands-on experience in modern production methods, making CNC training a catalyst for innovation and a stepping stone toward careers in robotics, aerospace, and medical device manufacturing.

CNC machining fosters an environment of creativity and iterative design. Students are encouraged to experiment with complex designs and push conventional boundaries. The process of designing, simulating, producing, and refining products promotes effective problem solving and creative innovation. This melding of art and science equips students with interdisciplinary skills transferable across various fields.

CNC machining finds application at every level of education—from early foundational programs to advanced university research—ensuring that all learners benefit from access to cutting-edge technology.

In K-12 education, CNC projects integrate into STEM curricula to spark early interest in engineering and design. Simple projects, such as keychains, puzzles, or basic architectural models, illustrate geometry, measurement, and tool usage. These activities provide young students with a practical understanding of math and science principles, build confidence, promote teamwork, and lay the groundwork for advanced technical learning.

Vocational programs use CNC machining to equip students with immediately applicable skills in metalworking, fabrication, and manufacturing. These programs emphasize machine operation, quality control, and routine maintenance—skills that lead to certifications and quicker job placements. Simulated production runs and case studies illustrate the importance of precision and efficiency, thereby enhancing employment prospects in competitive industrial sectors.

At the university level, CNC machining is a critical tool in research and prototyping. Engineering departments utilize CNC machines to overcome complex challenges—from aerospace components to medical devices. University labs leverage precision milling and intricate cutting techniques to support research projects. This hands-on experimentation nurtures innovation and interdisciplinary collaboration, blending design, engineering, and technology.

Beyond STEM, CNC machining transforms art and design education. Art schools use CNC routers and laser cutters to produce intricate sculptures, installations, and models that exceed manual capabilities. The ability to digitally design and then manufacture a piece pushes creative boundaries and stimulates exploration of the intersection between technology and art, leading to innovative hybrid art forms.

CNC machining is vital for robotics competitions and engineering challenges. Educational institutions use CNC technology to fabricate precise and robust components for competitive robots, drones, and automated systems. This application reinforces teamwork, strategic planning, and real-world problem solving. As students build machines for competitions, they gain valuable lessons in design optimization, material selection, and iterative prototyping—skills essential for future engineering careers.

Successful implementation of CNC machining programs requires careful planning, appropriate equipment selection, and an ongoing framework for learning. The following actionable steps outline how to integrate CNC technology into educational curricula effectively.

When choosing CNC equipment for schools, institutions must consider cost, safety, ease of use, and maintenance. Desktop CNC machines and smaller-scale routers are often recommended for their affordability and user-friendly interfaces. Equipment should include essential safety features, and vendors should provide training and technical support to help educators operate and maintain the machines.

Educational modules should bridge theoretical learning with hands-on practice. Lesson plans that integrate CAD/CAM software training with practical machining activities enable students to progress from simple projects to complex prototypes. Including assessments such as case studies, simulation results, and industry-standard practices ensures students are prepared for both academic and vocational applications.

Professional development for educators is critical for successful CNC programs. Teacher training should cover both technical aspects of CNC machining and effective hands-on teaching strategies. Workshops, vendor certifications, and continuous training opportunities build educators’ confidence and ensure that instruction remains aligned with industry standards.

Safety is paramount in CNC workshops. Schools must establish clear guidelines for personal protective equipment, machine operation, and emergency procedures. Regular safety audits and training sessions help familiarize students and staff with proper handling techniques, reducing risks and instilling a professional mindset.

Challenges such as budget constraints, inadequate training, and curricular integration are common when adopting CNC technology. These obstacles can be addressed by forming partnerships with local industries, applying for grants, and collaborating with technical colleges. Pilot programs and feedback from students and teachers can also help fine-tune the curriculum and ensure flexibility in scheduling and learning paces.

Integrating CNC machining into education not only enhances learning outcomes but also shapes a future workforce of innovators with advanced manufacturing skills. This approach transforms students into creative problem solvers with a practical understanding of digital manufacturing processes.

Early exposure to CNC machining provides a strong foundation for careers in advanced manufacturing. Hands-on experience with CNC tools enables students to grasp the complexities of modern production. Through practical projects, they learn to solve machining problems, optimize production processes, and master software that controls machine tools—preparing them for careers in aerospace, automotive, and medical device manufacturing.

CNC machining empowers students to rapidly prototype and test innovative ideas, reducing the gap between concept and product. This ability to transform abstract concepts into functional prototypes lowers production costs and accelerates time-to-market for student-led ventures. By promoting a "fail fast, learn faster" environment, educational institutions nurture entrepreneurial spirit and innovation.

As automation, robotics, and digital transformation reshape industries under the Industry 4.0 paradigm, CNC skills become increasingly critical. Familiarity with CNC technology enables students to understand how digital information interfaces with physical production systems, which is essential for smart manufacturing and IoT applications. This training ensures that graduates are ready to work in complex, automated production environments.

Success stories of students excelling through CNC machining serve as powerful motivation for peers. Educational institutions that highlight achievements—such as securing internships or launching product lines through CNC projects—create role models and inspire others to explore similar pathways in engineering and design.

Linking classroom CNC education with local industry demands creates a seamless transition from academic learning to professional practice. Collaborative programs with local manufacturers provide real-world projects, internships, and apprenticeships that enhance job placement rates and ensure curricula remain relevant to industry needs.

CNC machining in education is evolving as technological advancements reshape both classroom learning and manufacturing practices. Future trends point to a broader integration of CNC technologies across educational contexts.

Rapid improvements in cost efficiency, precision, and usability are making desktop CNC machines more robust and accessible. As these devices become increasingly affordable, their adoption in classrooms is set to grow, providing students with access to machinery that mirrors industry standards.

Innovations in CAD/CAM and simulation software are simplifying CNC design and operation. User-friendly programs reduce the learning curve, enabling students to create detailed models and simulate machining processes with ease. This software evolution supports deeper understanding and experimentation in everyday classroom activities.

Additive manufacturing (3D printing) is increasingly complementary to CNC machining. Integrating subtractive (CNC) and additive techniques offers a holistic view of modern production methods. This combination broadens the learning scope, allowing students to optimize designs, reduce material waste, and develop more efficient production processes.

The future of CNC education may involve networked classrooms where connected CNC machines share designs, troubleshooting techniques, and project outcomes in real time. Such collaborative environments encourage knowledge exchange and cross-institutional projects, enriching the learning experience by exposing students to diverse perspectives.

Long-term sustainability of CNC programs requires continuous investment in updated technology, ongoing instructor training, and curriculum development. Strategic partnerships with industry leaders and technology providers ensure that educational institutions have access to state-of-the-art equipment and software, keeping curricula aligned with the latest trends and supporting a skilled future workforce.

CNC machining in education creates a powerful synergy between theoretical learning and practical application. It equips students with essential hands-on skills for advanced manufacturing careers while fostering creativity and critical thinking. By integrating CNC technology into curricula, educational institutions bridge the gap between classroom instruction and real-world industry, preparing a future workforce ready for the challenges of Industry 4.0 and beyond.

Q: What makes CNC machining an essential tool in education?

A: CNC machining provides hands-on experience that bridges digital design and physical production, fostering practical skills, critical thinking, and technical proficiency.

Q: How does CNC machining improve student engagement in STEM subjects?

A: By allowing students to see tangible results from their designs, CNC machining transforms abstract concepts into practical projects, enhancing understanding and enthusiasm.

Q: What types of CNC machinery are most suitable for classrooms?

A: Desktop CNC mills, CNC routers, and compact laser cutters are ideal due to their safety features, ease of use, and affordability, making them suitable for both introductory and advanced projects.

Q: How is CNC machining integrated into art and design curricula?

A: In art and design, CNC machines are used for precise engraving, cutting, and sculpture creation, merging technology with creativity to produce innovative designs.

Q: What are some challenges of adopting CNC technology in schools and how can they be overcome?

A: Challenges include budget constraints, teacher training, and curriculum integration. These can be managed through industry partnerships, grants, pilot programs, and comprehensive training for educators.

We Are Happy To Help You! - Serving Clients Worldwide From China - Dedicated Project Manager.

No MOQ | Quality & Precision | Fast Turnaround | Rapid Prototypes | Low-Volume To Mass Production | Global Delivery

You can submit your designs to us through our contact us page

OR Email to info@wjprototypes.com