Our Custom Injection Molding Services

Make the move from prototyping to on-demand manufacturing for affordable, high-quality molded parts within days. Better yet, your prototyping tool is free once you shift to an on-demand manufacturing tool. Working with a single supplier that provides free design consultation services also massively speeds up the manufacturing process, allowing for greater supply chain flexibility, more consistent parts, and making qualification a breeze.

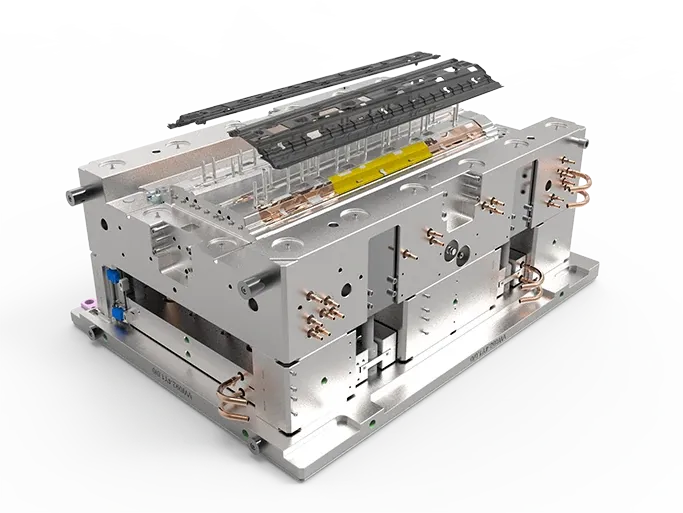

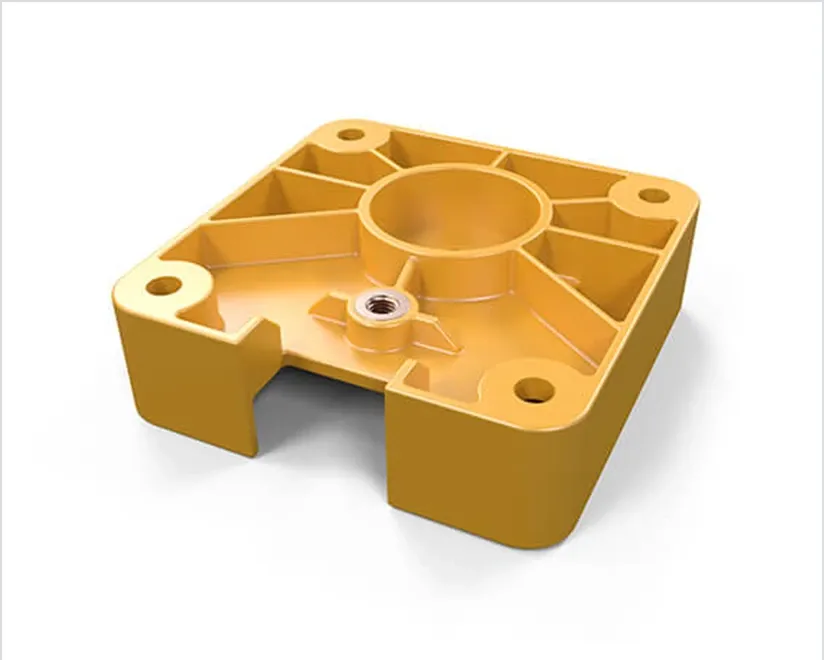

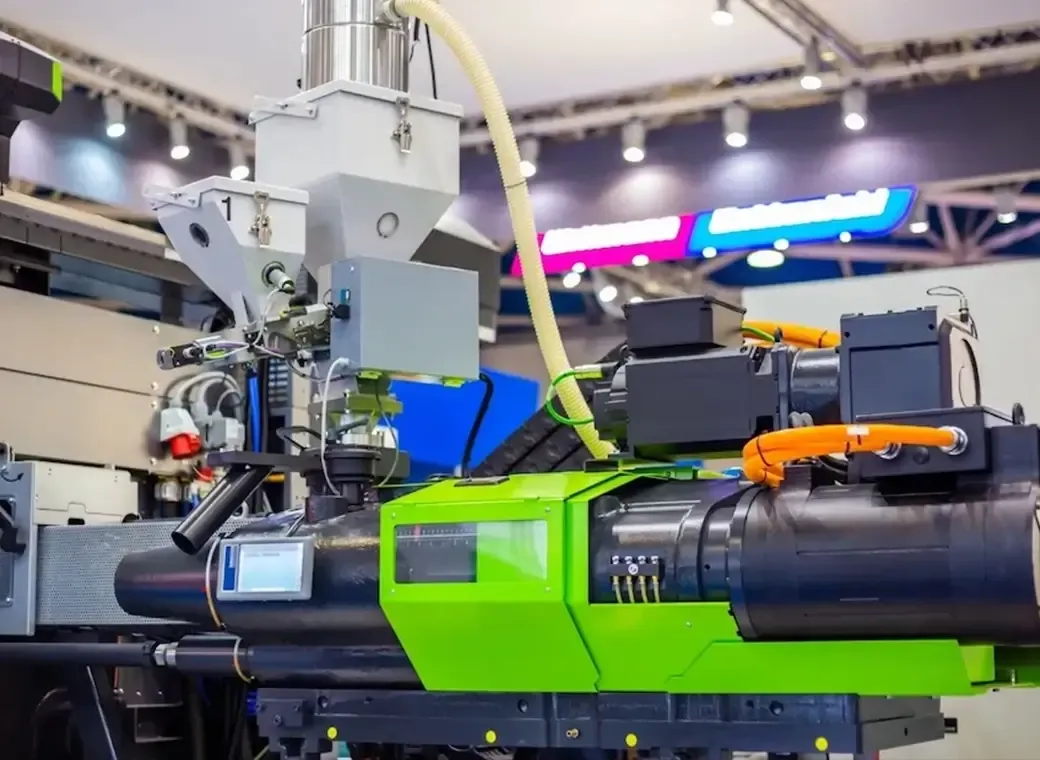

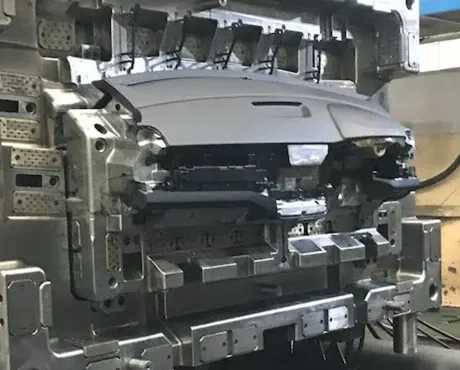

Plastic injection molding is a manufacturing process where resin in a barrel is heated to a molten state, then shot into a mold to form a final production-grade thermoplastic part.

Liquid silicone rubber molding is a thermoset process that mixes a two-component compound together, which is then heat cured in the mold with a platinum catalyst to produce a final part.

A manufacturing process in which a part is molded around a pre-installed insert in the tooling.

A manufacturing process in which one plastic material is molded over another to create a single component.

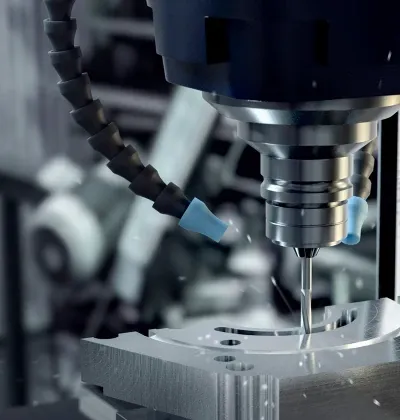

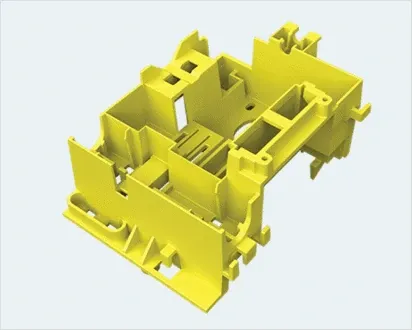

What Is Injection Molding?

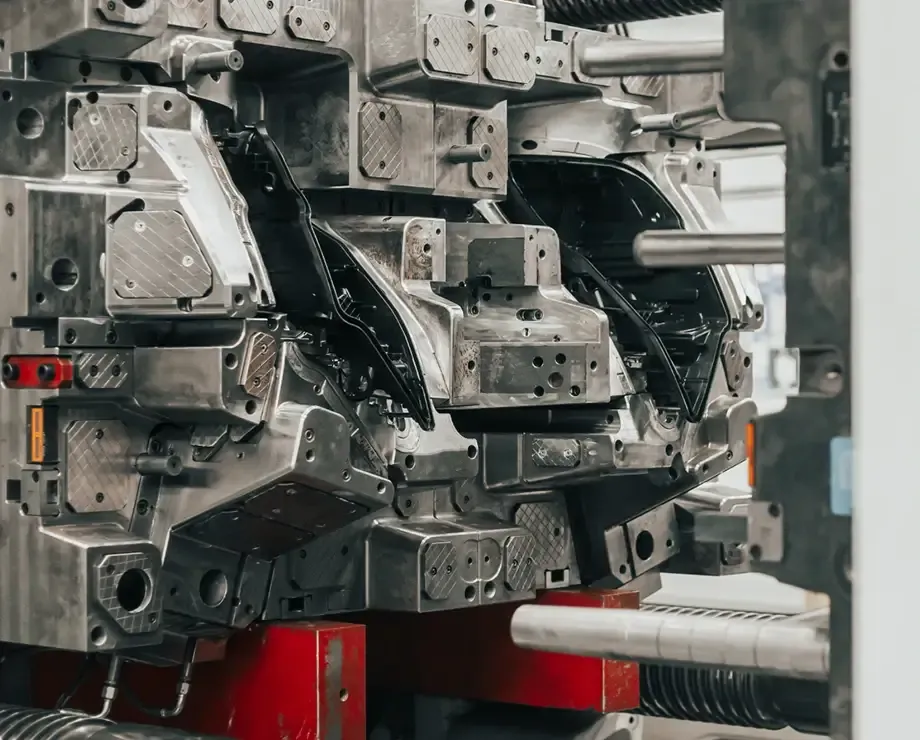

Injection molding is the most cost-effective way to make a plastic part at scale. The injection molding process involves injecting molten plastic into a mold tool, then ejecting the solidified part. This process quickly repeats hundreds or thousands of times, amortizing the cost of the mold tool and driving down the cost of each unit to a few dollars or less. Since the injection molding process uses the same mold tool for each part, it offers consistent quality across every part. Injection molding also has the highest variety of materials, colors, cosmetics, polishes, and surface textures when compared to CNC machining or even 3D printing.

150+

Experienced Engineers

200+

Up-to-date Machines

5000+

Satisfied customers

Advantages of Injection Molding

Injection molding is plastic manufacturing process that can produce high quality parts at scale. It's typically used for low- to high-volume production but our aluminum tooling can also make prototyping runs economical.

Why Choose Us for Custom Injection Molding?

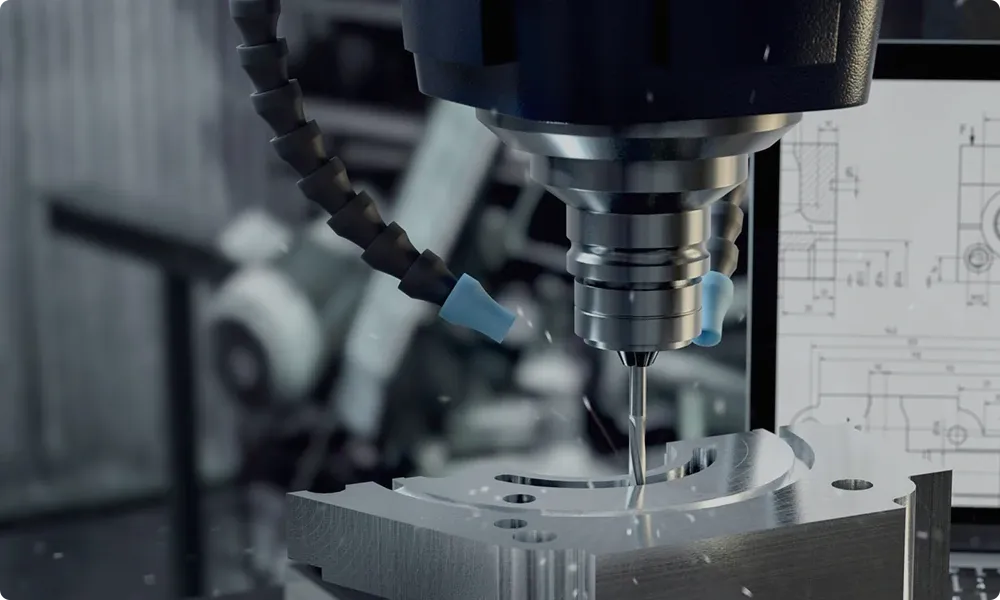

Unmatched Lead Times

Reduce your product development cycle by weeks—sometimes months—and bridge to production with injection-molded parts within days. Some injection molding orders can ship in as fast as 1 day.

Design for Manufacturing Feedback

Every quote includes real-time pricing and design analysis. We evaluate your 3D CAD and help identify any features that may pose challenges during the molding process such as difficult to machine undercuts and insufficient draft.

No Minimum Order Quantities (MOQs)

Procuring parts on demand, without MOQs, helps you manage market or demand volatility and provides a cost-effective source for bridge production, line-down emergencies, end-of-life production, or product customization.

Injection Molding Expertise

We'll work with you throughout the course of your project to help you quickly move from prototyping to production, including finishing options and inspection reporting.

Injection Molding Materials

Surface Finish Options for Injection Molding

Surface finishes can serve either a functional or aesthetic purpose. Surface finishes that serve both purposes are deemed cosmetic finishes, and are used for cosmetic parts. Producing cosmetic parts requires additional measures to minimize defects such as hang marks and scratches from tools.

Clear Coat

Clear cosmetic finish that can be applied to ABS-Like Translucent/Clear (WaterShed XC 11122) and PC-Like Translucent/Clear (Accura 60) materials.

Painting

After smoothing the part with sanding and polishing, parts can be painted with automotive-grade paint. Provide a pantone color with your quote request. We also offer soft-touch painting.

Plating

Electroless nickel plating can be used to achieve parts that are similar to cast aluminum or magnesium.

Dyeing

Dyeing is another method for adding color to 3D prints. This is faster option with a limited color selection, so is a more cost-effective choice than painting.

Decaling

Decaling can be used to add a logo or other graphics to boost cosmetics or function.

Polishing

We can polish parts to a mirror-like finish. If this is a requirement, we ask that you provide either a drawing or image that indicates your finish expectations.

Heat Treatment

Harden and strengthen metal 3D prints with multiple heat treatment options: NADCAP heat treatment, hot isostatic pressing (HIP), solution annealing, and aging.

Get An Instant Quote

undefined

Testimonials / Satisfied Customers

Dorothy

Buyer at Leading Energy company

WJ Prototypes is Great!

“We’re glad we recently added WJ Prototypes to our AVL. You guys are always quick and friendly and all the Machining jobs we have sent have gone smoothly!”

Thomas

Engineer at Robotics Company

Our No.1 source for CNC parts

“We had a time sensitive Sheet Metal enclosure with fairly strict cosmetic requirements. WJ Prototypes came through for us and the parts looked great. The full build turned some heads at our Trade Show!”

Marc

Buyer at Electric Car Company

Great prices, lead times, and quality of work

“You guys are one of the easiest job shops I’ve worked with the last 10 years. You are responsive and competitive. We’ve appreciated the awesome work!”