- Room 1807, Unit 9, Building 2, Shangxing Commercial Street, Shangde Road, Shangxing Community, Xinqiao Subdistrict, Bao'an District, Shenzhen City, China

Aerospace & UAV

WJ Prototypes is your 3D manufacturing partner from prototype to large scale production.

Consumer Electronics

New Product Introduction Solutions for Consumer Electronics.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Automotive

New Product Introduction Solutions for Automotive

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

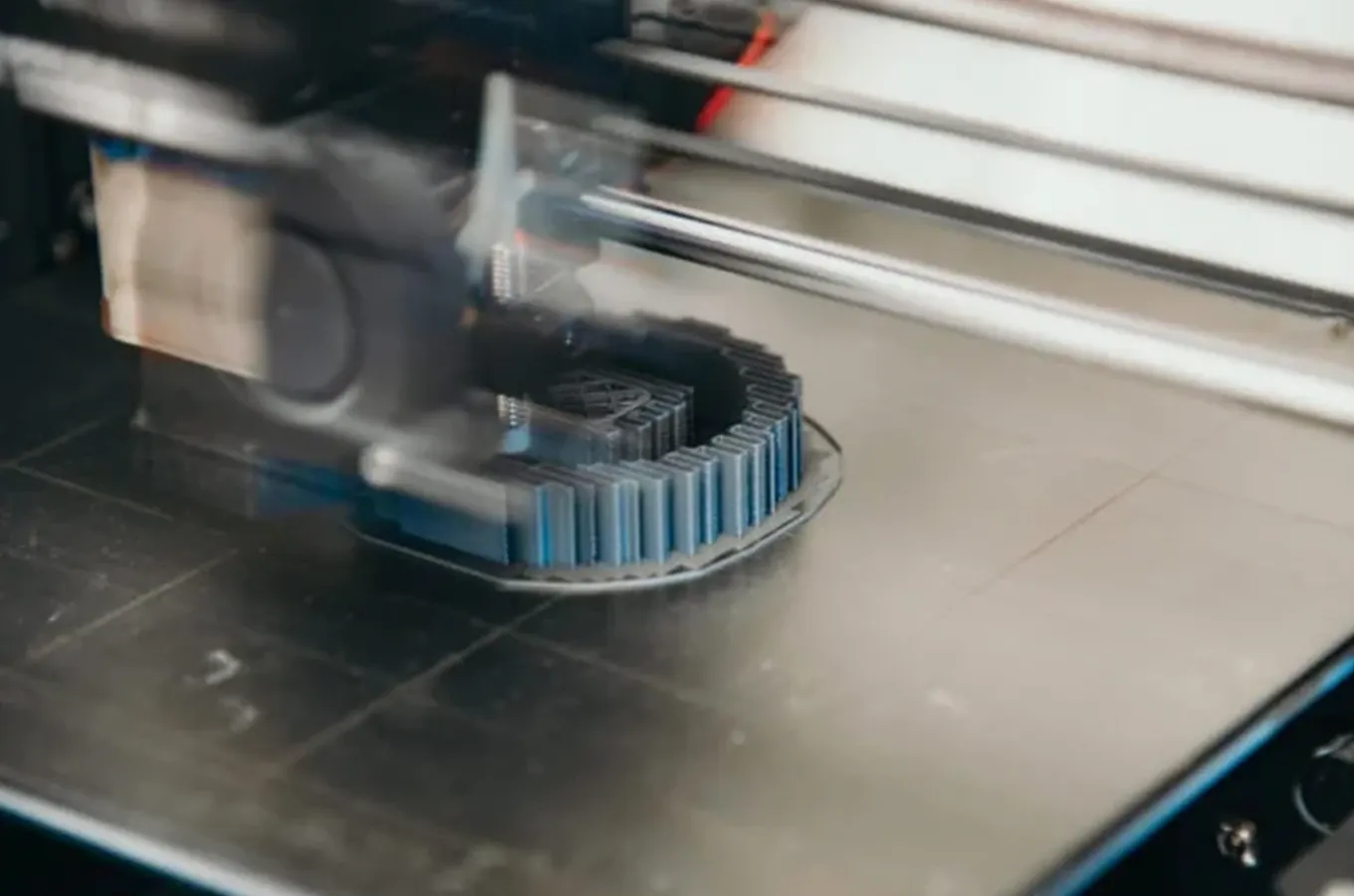

Source high-performing parts for rapid prototyping and low-volume industrial production with FDM 3D printing. We offer FDM for quick-turn manufacturing using a variety of robust materials for many use cases and can print parts in 1 day.

Maximum Build Size:

750 × 750 × 750 mm

Standard Lead Time:

6 business days

Dimensional Accuracy:

± 0.5% with a Lower limit of ± 0.15 mm (± 0.006")

Layer Height:

25-100 um

150+

Experienced Engineers

200+

Up-to-date Machines

5000+

Satisfied customers

Fused Deposition Modeling (FDM) is a 3D Printing technology widely known for its great material selection, accuracy, possibility to print large parts, and affordability. FDM 3D Printing machines produce one layer at a time by extruding thermoplastic filament onto a build plate. FDM 3D Printed parts are great for end-use, low-volume production, and for rapid prototyping. They also usually don’t require any post-processing.

FDM is the most cost-effective way to produce custom thermoplastic parts and prototypes.

Lead times are short (typically a few days).

A wide range of materials is available, suitable for prototyping and industrial applications.

FDM is not suitable for parts with very small details due to its low resolution.

Parts are likely to have visible layer lines, so post-processing is required for a smooth finish.

The layer adhesion mechanism makes parts inherently anisotropic.

Surface finishes can serve either a functional or aesthetic purpose. Surface finishes that serve both purposes are deemed cosmetic finishes, and are used for cosmetic parts. Producing cosmetic parts requires additional measures to minimize defects such as hang marks and scratches from tools.

Clear Coat

Clear cosmetic finish that can be applied to ABS-Like Translucent/Clear (WaterShed XC 11122) and PC-Like Translucent/Clear (Accura 60) materials.

Painting

After smoothing the part with sanding and polishing, parts can be painted with automotive-grade paint. Provide a pantone color with your quote request. We also offer soft-touch painting.

Plating

Electroless nickel plating can be used to achieve parts that are similar to cast aluminum or magnesium.

Dyeing

Dyeing is another method for adding color to 3D prints. This is faster option with a limited color selection, so is a more cost-effective choice than painting.

Decaling

Decaling can be used to add a logo or other graphics to boost cosmetics or function.

Polishing

We can polish parts to a mirror-like finish. If this is a requirement, we ask that you provide either a drawing or image that indicates your finish expectations.

Heat Treatment

Harden and strengthen metal 3D prints with multiple heat treatment options: NADCAP heat treatment, hot isostatic pressing (HIP), solution annealing, and aging.

01

Get An Instant Quote

02

Confirm Specifications

03

Manufacturing Begins

04

Parts Are Shipped

Dorothy

Buyer at Leading Energy company

WJ Prototypes is Great!

“We’re glad we recently added WJ Prototypes to our AVL. You guys are always quick and friendly and all the Machining jobs we have sent have gone smoothly!”

Thomas

Engineer at Robotics Company

Our No.1 source for CNC parts

“We had a time sensitive Sheet Metal enclosure with fairly strict cosmetic requirements. WJ Prototypes came through for us and the parts looked great. The full build turned some heads at our Trade Show!”

Marc

Buyer at Electric Car Company

Great prices, lead times, and quality of work

“You guys are one of the easiest job shops I’ve worked with the last 10 years. You are responsive and competitive. We’ve appreciated the awesome work!”