- Room 1807, Unit 9, Building 2, Shangxing Commercial Street, Shangde Road, Shangxing Community, Xinqiao Subdistrict, Bao'an District, Shenzhen City, China

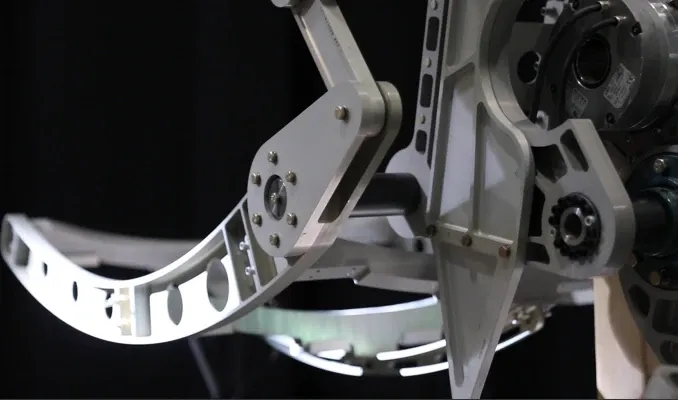

Aerospace & UAV

WJ Prototypes is your 3D manufacturing partner from prototype to large scale production.

Consumer Electronics

New Product Introduction Solutions for Consumer Electronics.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Automotive

New Product Introduction Solutions for Automotive

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

Speed and reliability are key during the design, validation, and launch of aerospace components. Our CNC machining services support demanding production schedules by offering technical design expertise and validation, the ability to prototype in final materials, and quick turnaround for complex designs.

These durable materials are built for robust aerospace applications and can take the heat

Aluminum. This versatile metal’s high strength-to-weight ratio, heat tolerance, and corrosion resistance make it an ideal candidate for Aerospace parts.

Stainless Steel. SS 17-4 PH works well for the aerospace parts due to its high tensile strength, corrosion resistance, and high heat tolerance (up to 600°F).

Titanium. Commonly used in aircraft jet engines and spacecraft, this metal is strong, yet lightweight with excellent corrosion and temperature resistance.

We commonly machine components included in planes, rockets, satellites, and drones. Some examples include: