Our Sheet Metal Services Capabilities

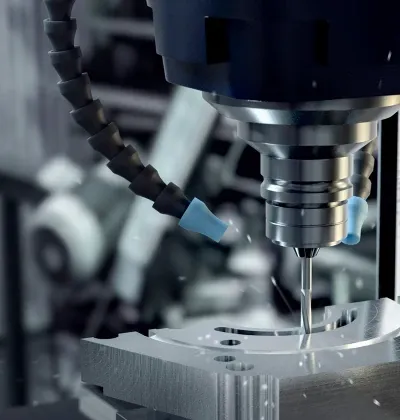

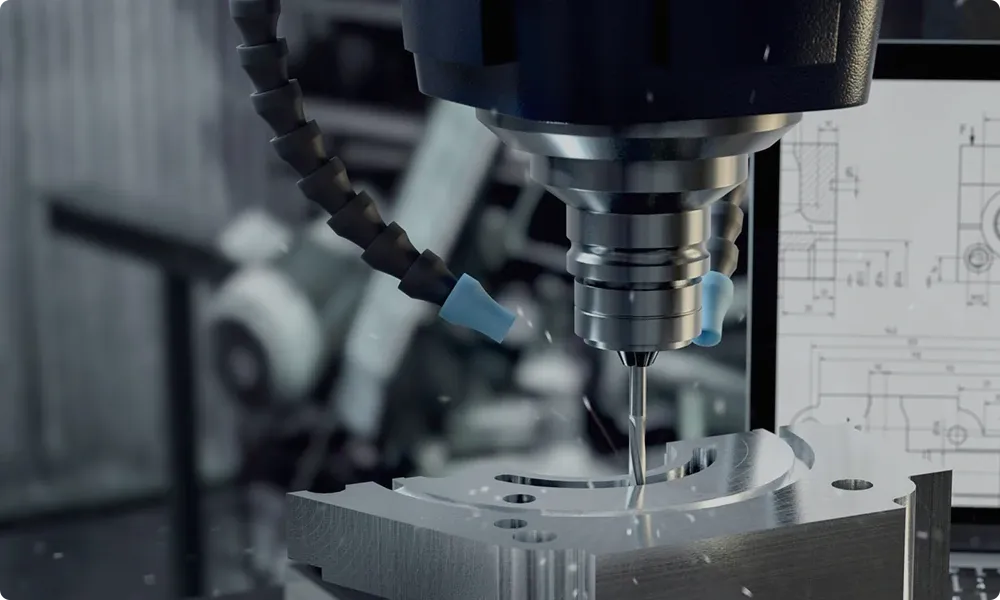

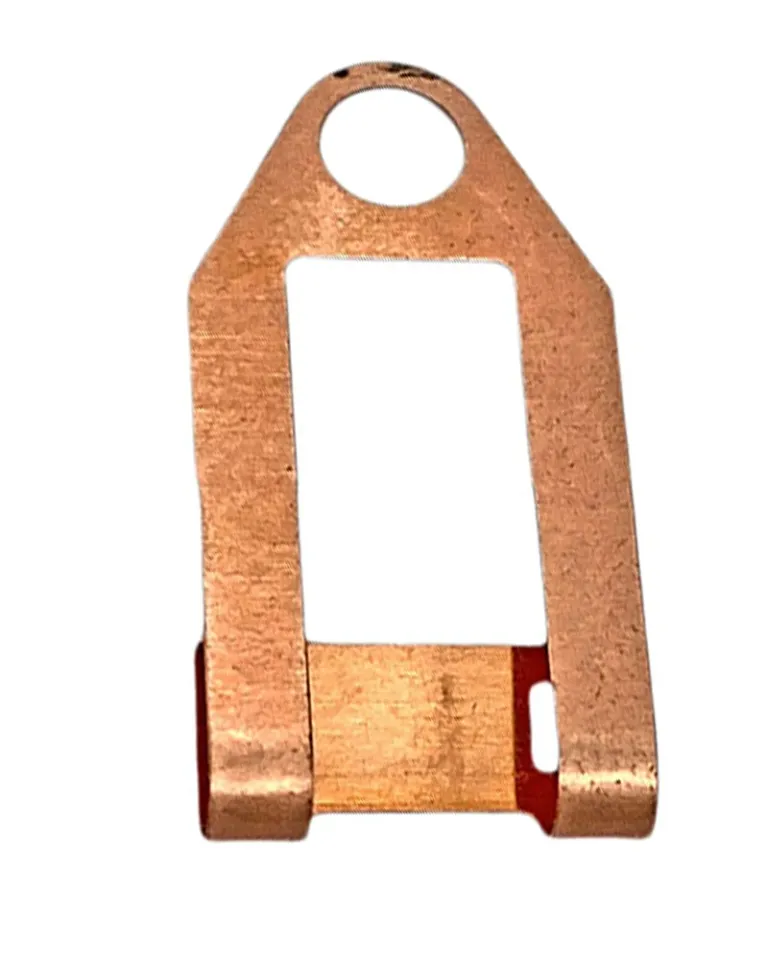

We takes on prototype and production sheet metal services and cutting. We can support one-offs, batch production, welding and assembly as well as stockholding in line with your requirements. Our engineers are here to take on challenging complex jobs, be it complex part geometry, specialist materials, extremely tight tolerances or specialist finishing. We have earned our reputation amongst the world's leading companies for high-quality and precision sheet metal services, working on the very latest of technologies.

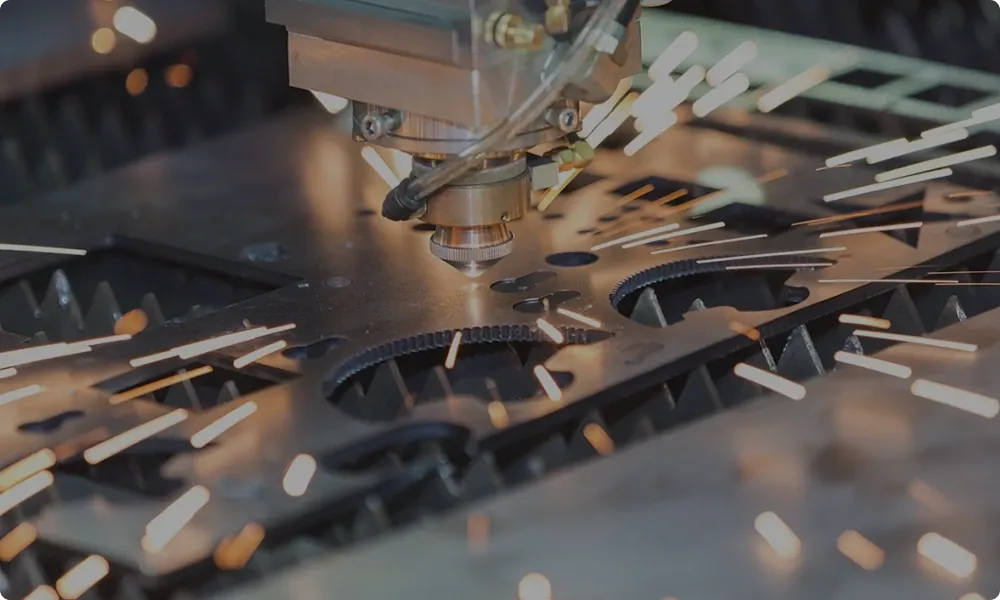

We offer high-precision fibre and CO2 Laser Cutting to produce the most accurate cuts and contours possible to flat metal sheets.

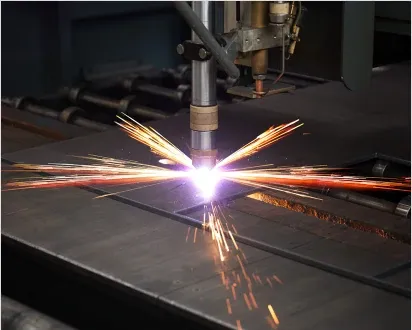

Plasma cutting is widely used in custom sheet metal services, it is especially suitable for custom cutting of thicker sheet metals.

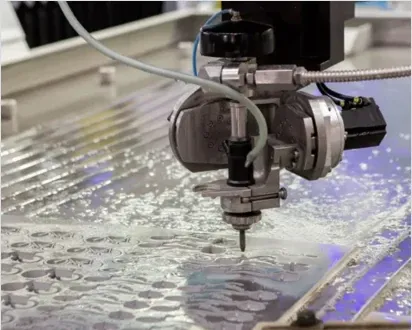

Our Waterjet Cutting service is ideal for cutting Sheet Metal components between 18mm-40mm.

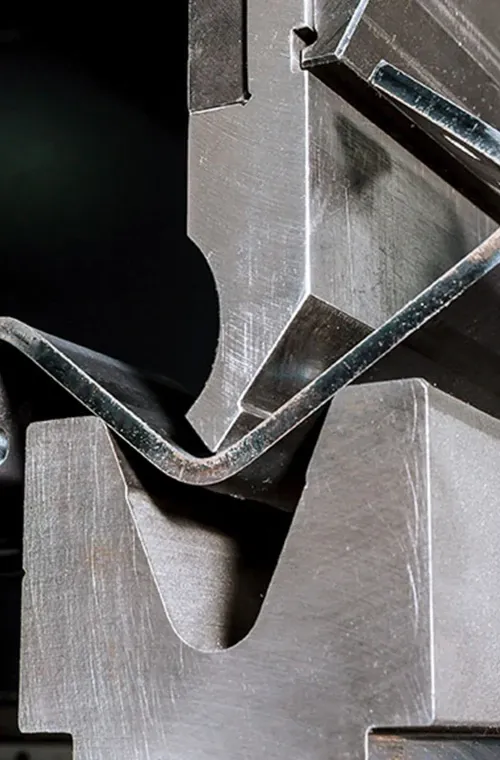

Whether you’re after magnetic or hydraulic bending of Sheet Metal components, we’ve got you covered.

How Does Sheet Metal Fabrication Work?

During the sheet metal fabrication process, thin sheet metal stock is placed on a flat bed where a laser cutter (1) draws programmed part patterns. Depending on the part geometry, a sheet metal punch (2) can form additional features. Once the parts are deburred, they move to the press brake (3) where they are formed into the final geometries. Additional secondary operations are often used to finish the sheet metal parts.

150+

Experienced Engineers

200+

Up-to-date Machines

5000+

Satisfied customers

Advantages of Sheet Metal Fabrication

The sheet metal fabrication process is ideal for metal components and can support both prototyping and production. quantities.

Why Choose Us for Custom Sheet Metal Fabrication?

Rapid turnaround

Order now to receive your custom sheet metal parts in as little as 5 days! Put in your instant quote for sheet metal now!

The perfect finish

We offer functional or cosmetic sheet metal and finishing processes; from polishing and plating to powder coating and more.

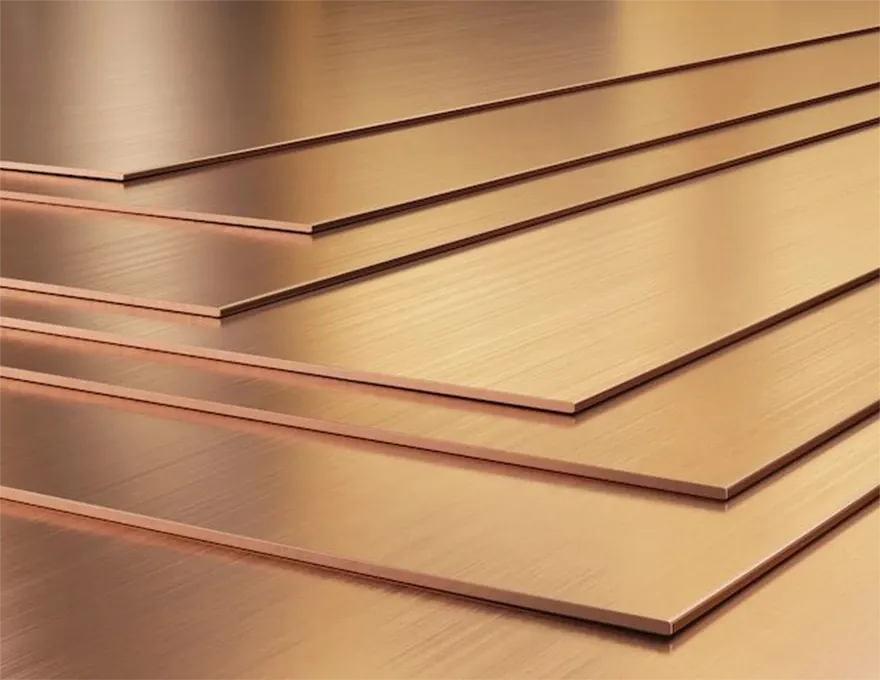

A wide variety of materials

We offer most gauges of steels, copper, aluminium and more, in various thicknesses as part of our wide range of materials for sheet metal.

Unmatched scalability

We offer one-off prototypes, complex fabrications, assemblies, and up to 50,000 units at the most competitive prices. Our engineers provide project management and can support annual stockholding for long-term, cost-effective production.

Sheet Metal Materials

Surface Finish Options for Sheet Metal

Surface finishes can serve either a functional or aesthetic purpose. Surface finishes that serve both purposes are deemed cosmetic finishes, and are used for cosmetic parts. Producing cosmetic parts requires additional measures to minimize defects such as hang marks and scratches from tools.

Clear Coat

Clear cosmetic finish that can be applied to ABS-Like Translucent/Clear (WaterShed XC 11122) and PC-Like Translucent/Clear (Accura 60) materials.

Painting

After smoothing the part with sanding and polishing, parts can be painted with automotive-grade paint. Provide a pantone color with your quote request. We also offer soft-touch painting.

Plating

Electroless nickel plating can be used to achieve parts that are similar to cast aluminum or magnesium.

Dyeing

Dyeing is another method for adding color to 3D prints. This is faster option with a limited color selection, so is a more cost-effective choice than painting.

Decaling

Decaling can be used to add a logo or other graphics to boost cosmetics or function.

Polishing

We can polish parts to a mirror-like finish. If this is a requirement, we ask that you provide either a drawing or image that indicates your finish expectations.

Heat Treatment

Harden and strengthen metal 3D prints with multiple heat treatment options: NADCAP heat treatment, hot isostatic pressing (HIP), solution annealing, and aging.

Get An Instant Quote

undefined

Testimonials / Satisfied Customers

Dorothy

Buyer at Leading Energy company

WJ Prototypes is Great!

“We’re glad we recently added WJ Prototypes to our AVL. You guys are always quick and friendly and all the Machining jobs we have sent have gone smoothly!”

Thomas

Engineer at Robotics Company

Our No.1 source for CNC parts

“We had a time sensitive Sheet Metal enclosure with fairly strict cosmetic requirements. WJ Prototypes came through for us and the parts looked great. The full build turned some heads at our Trade Show!”

Marc

Buyer at Electric Car Company

Great prices, lead times, and quality of work

“You guys are one of the easiest job shops I’ve worked with the last 10 years. You are responsive and competitive. We’ve appreciated the awesome work!”