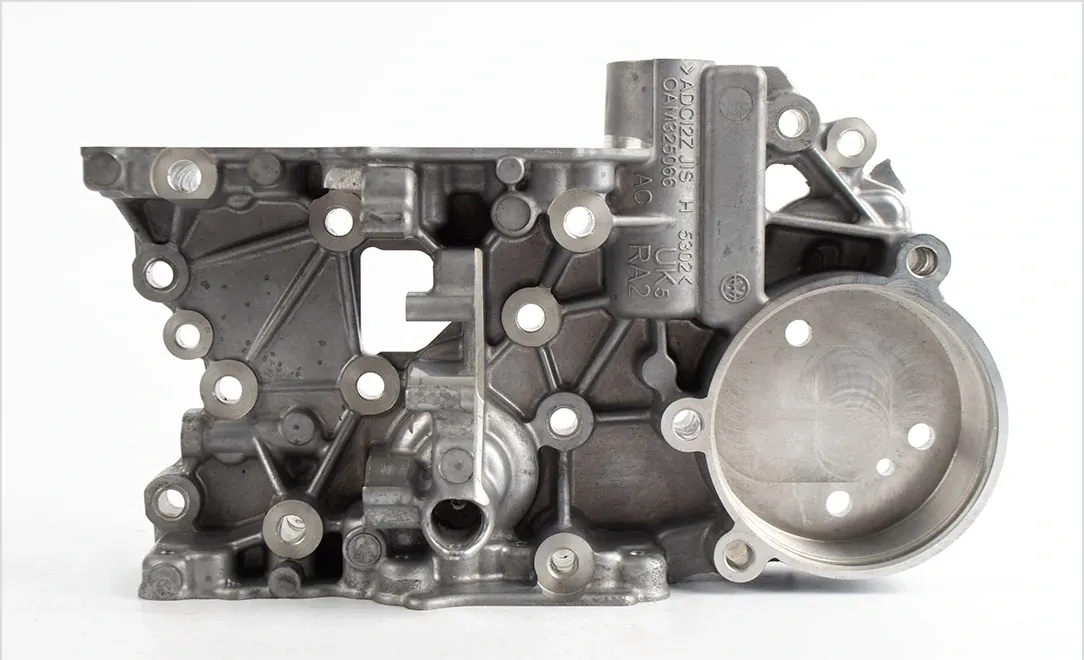

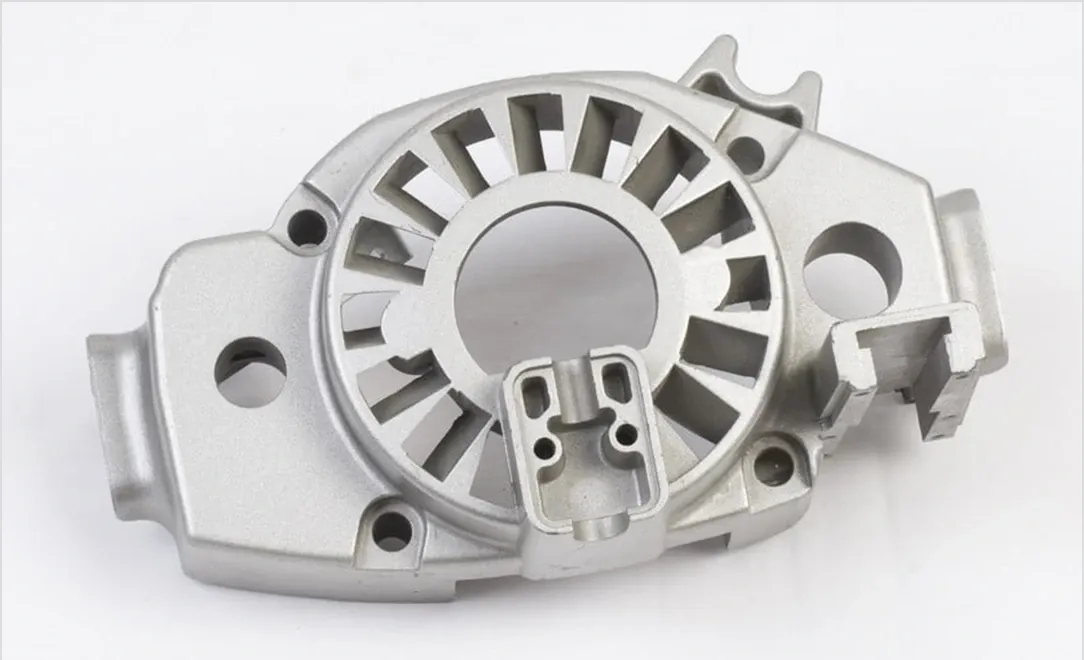

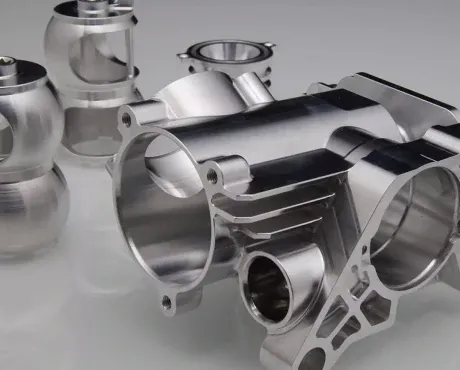

Our CNC Machining Services

At WJ Prototypes, we're experts in CNC machining production and prototyping, ready to meet your specific needs. Whether you're after precision for smaller quantities or large-scale production, our services are tailored just for you.

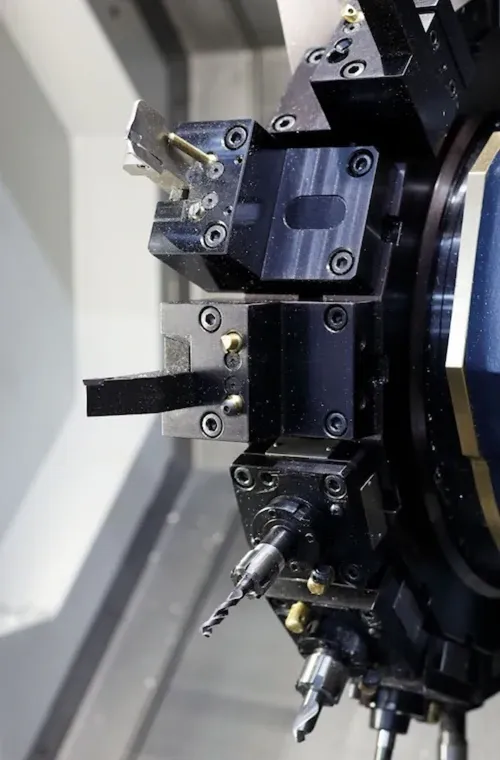

Multi-axis 3 & 5 axis CNC machining from our global supply chain provides one-off prototypes to large-scale production, ensuring consistent quality and lead times.

CNC Turning from our global supply chain offers one-off CNC prototypes to large-scale production.

What is CNC Machining?

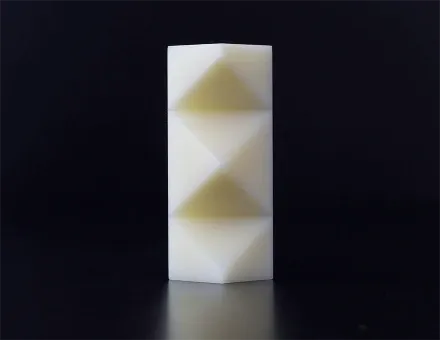

CNC, or computer numerical control machining, is a widely used manufacturing process that uses automated, high-speed cutting tools to remove material from a metal or plastic workpiece until the desired geometry is achieved. Standard CNC machines include 3-axis, 4-axis, and 5-axis milling machines, lathes, and routers. CNC machines can cut almost any material such as metal alloys, plastics, wood, stones, ceramics and more. Making custom machined parts needed for nearly every industry, including automotive, robotics, medical, aerospace, electronics and industrial.

150+

Experienced Engineers

200+

Up-to-date Machines

5000+

Satisfied customers

Advantages of CNC Machining

The subtractive process of CNC machining provides multiple benefits for both prototyping and production parts.

Why Choose Us for Custom CNC Machining?

Fast and Reliable Delivery

Iterate part designs quickly and accelerate product development with quick-turn parts. Our automated design analysis will help spot any difficult to machine features before your design is sent to the manufacturing floor and save you from costly reworks further down the product development cycle.

Advanced Capabilities

Get anodizing, tighter tolerances, and volume pricing options through our network of manufacturers at WJ Prototypes. You'll find plating (black oxide, nickel), anodizing (Type II, Type III), and chromate coating in larger part quantities; tolerances down to ±0.001 in. (0.020mm); and cost-efficient machined parts at higher volumes to lower piece-part price.

Material Selection

We stock more than 30 engineering-grade plastic and metal materials that are suitable for various part applications and industries. Materials range from plastics like ABS, polycarbonate, nylon, and PEEK to aluminum, stainless steel, platinum, and copper.

Infinite Capacity

Eliminate downtime spent waiting for parts and safeguard in-house machining with on-demand relief and infinite manufacturing capacity.

CNC Machining Materials

Surface Finish Options for CNC Machining

Surface finishes can serve either a functional or aesthetic purpose. Surface finishes that serve both purposes are deemed cosmetic finishes, and are used for cosmetic parts. Producing cosmetic parts requires additional measures to minimize defects such as hang marks and scratches from tools.

Clear Coat

Clear cosmetic finish that can be applied to ABS-Like Translucent/Clear (WaterShed XC 11122) and PC-Like Translucent/Clear (Accura 60) materials.

Painting

After smoothing the part with sanding and polishing, parts can be painted with automotive-grade paint. Provide a pantone color with your quote request. We also offer soft-touch painting.

Plating

Electroless nickel plating can be used to achieve parts that are similar to cast aluminum or magnesium.

Dyeing

Dyeing is another method for adding color to 3D prints. This is faster option with a limited color selection, so is a more cost-effective choice than painting.

Decaling

Decaling can be used to add a logo or other graphics to boost cosmetics or function.

Polishing

We can polish parts to a mirror-like finish. If this is a requirement, we ask that you provide either a drawing or image that indicates your finish expectations.

Heat Treatment

Harden and strengthen metal 3D prints with multiple heat treatment options: NADCAP heat treatment, hot isostatic pressing (HIP), solution annealing, and aging.

Get An Instant Quote

undefined

Testimonials / Satisfied Customers

Dorothy

Buyer at Leading Energy company

WJ Prototypes is Great!

“We’re glad we recently added WJ Prototypes to our AVL. You guys are always quick and friendly and all the Machining jobs we have sent have gone smoothly!”

Thomas

Engineer at Robotics Company

Our No.1 source for CNC parts

“We had a time sensitive Sheet Metal enclosure with fairly strict cosmetic requirements. WJ Prototypes came through for us and the parts looked great. The full build turned some heads at our Trade Show!”

Marc

Buyer at Electric Car Company

Great prices, lead times, and quality of work

“You guys are one of the easiest job shops I’ve worked with the last 10 years. You are responsive and competitive. We’ve appreciated the awesome work!”