- Room 1807, Unit 9, Building 2, Shangxing Commercial Street, Shangde Road, Shangxing Community, Xinqiao Subdistrict, Bao'an District, Shenzhen City, China

Aerospace & UAV

WJ Prototypes is your 3D manufacturing partner from prototype to large scale production.

Consumer Electronics

New Product Introduction Solutions for Consumer Electronics.

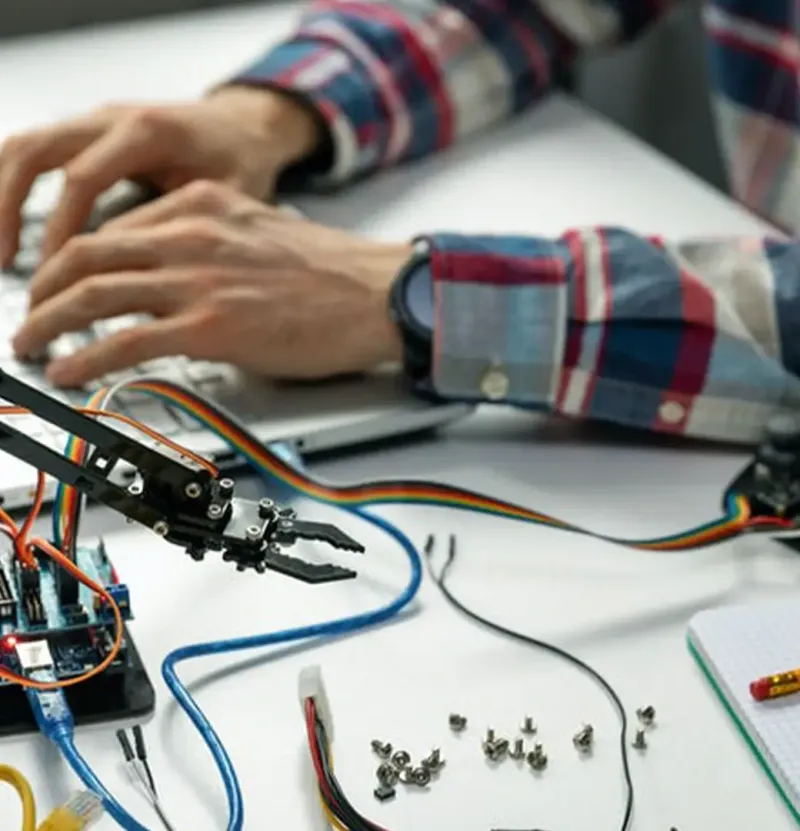

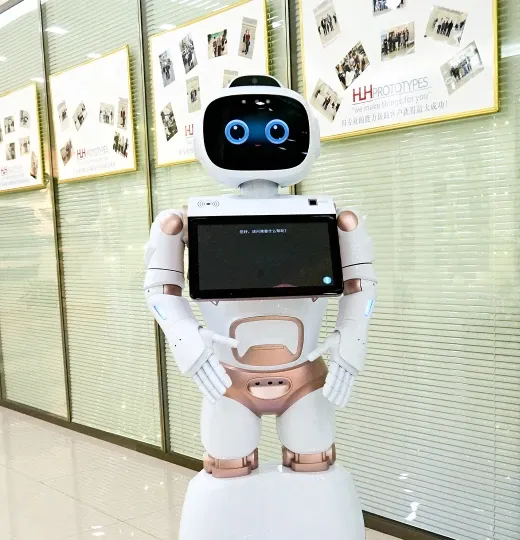

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Automotive

New Product Introduction Solutions for Automotive

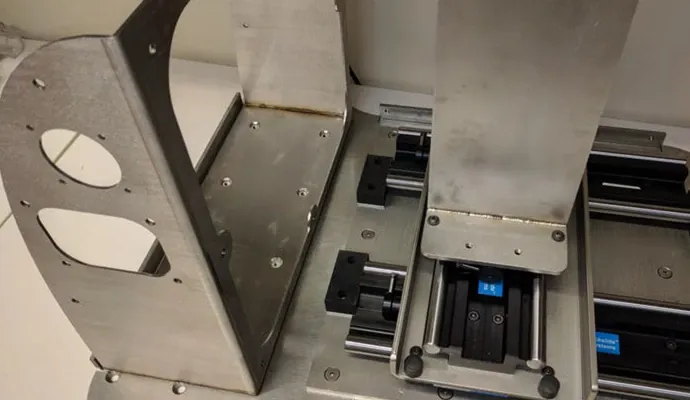

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

3D printing is increasingly being used in the robotics industry due to its ability to produce organic, complex, and efficient additive parts. It offers endless possibilities regarding geometries that may not be possible with machining or molding and has a broad material selection of plastics and metals. Additive manufacturing also allows for multi-part assemblies to be combined into a single design, saving production dollars.

These durable materials are built for robust aerospace applications and can take the heat

Rapid prototyping

Design versatility for organic features and complex geometries, including lattice structures

Weight reduction Manufacture of parts in a single part, saving time on assembly

Waste reduction

Injection molding is frequently used within the automotive industry to manufacture quality plastic parts at production volumes. Common applications include: