- Room 1807, Unit 9, Building 2, Shangxing Commercial Street, Shangde Road, Shangxing Community, Xinqiao Subdistrict, Bao'an District, Shenzhen City, China

Aerospace & UAV

WJ Prototypes is your 3D manufacturing partner from prototype to large scale production.

Consumer Electronics

New Product Introduction Solutions for Consumer Electronics.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Automotive

New Product Introduction Solutions for Automotive

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

Could combining rigid, flexible and transparent materials in a single print revolutionize your product development timeline? Multi-material 3d printing for efficient prototyping and production delivers this capability, reducing part count, assembly complexity and iteration cycles. In this guide, you will discover:

Blending design freedom with production viability, this advanced additive manufacturing approach in China unlocks new possibilities for product designers and DFM engineers, helping you move from concept to market faster than ever.

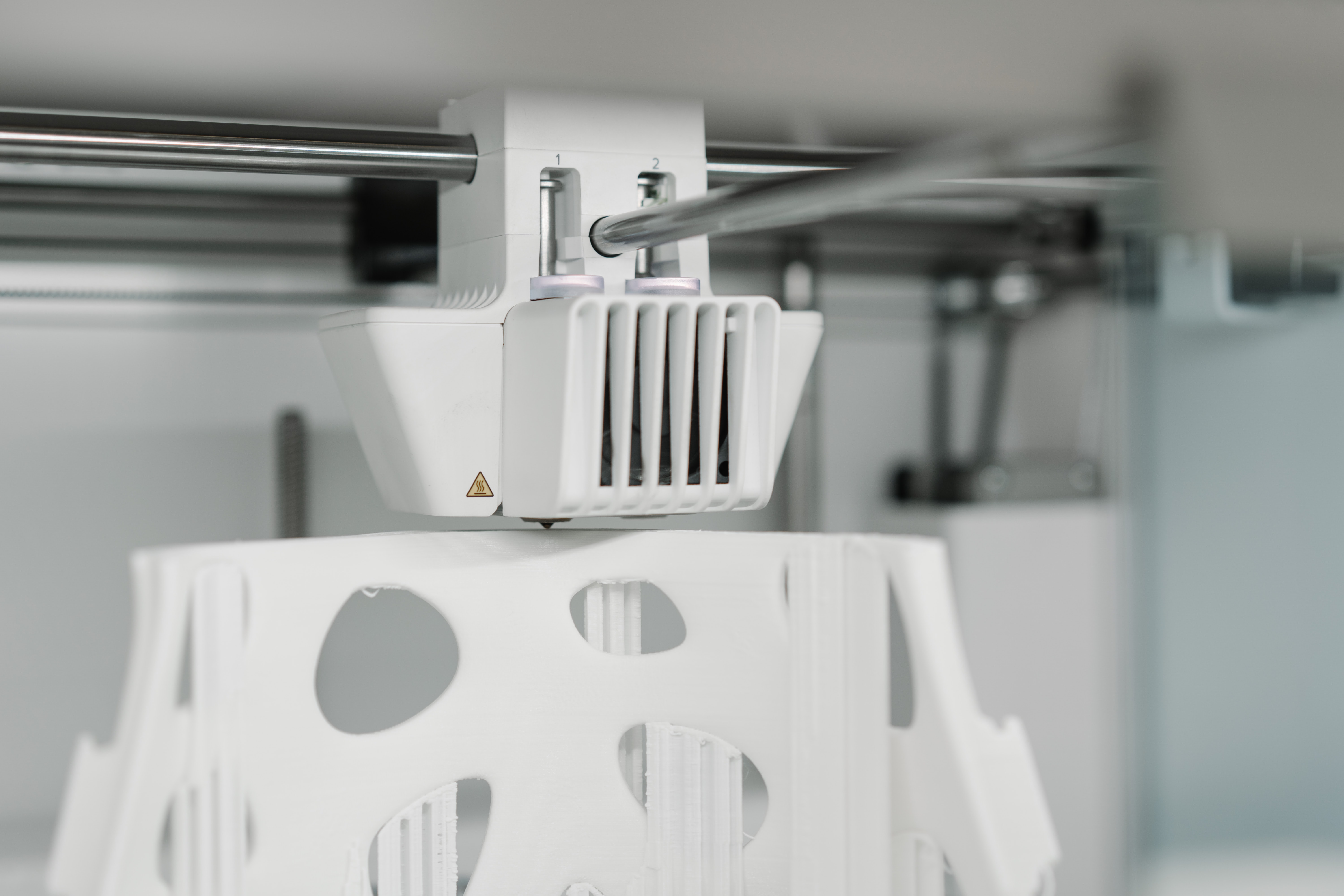

Multi-material 3D printing uses multiple print heads or sequential material deposition to fabricate a single component with varied mechanical, thermal and aesthetic properties. By eliminating secondary assembly and manual bonding, this process streamlines prototype iterations and functional testing. For product developers facing tight deadlines, integrating diverse materials in one build offers unprecedented speed and design flexibility.

China hosts several leading-edge multi-material 3D printing companies that cater to a wide spectrum of industrial needs, from prototyping to production. For instance, Chinese 3D printing providers offers a versatile platform—including DMLS (metal), PolyJet (multi-material plastics), FDM, SLS, SLA, MJF, and Carbon DLS processes—enabling complex multi-material builds with flexible post-processing options like anodizing, powder coating, and chrome finishing.

3D Printing companies in China also provides industrial-grade multi-material 3D printing, delivering plastic, metal, and elastomeric parts across six technologies—with full automation, rapid turnaround, and ISO certifications.

Additionally, WJ Prototypes' 3D Printing Services in China supports an integrated workflow using DMLS, MJF, SLA, SLS, and FDM, backed by in-house scanning, modeling, and streamlined production scalability.

We Are Happy To Help You! - Serving Clients Worldwide From China - Dedicated Project Manager.

No MOQ | Quality & Precision | Fast Turnaround | Rapid Prototypes | Low-Volume To Mass Production | Global Delivery

Talk To Our Certified Engineers. Send Your Requirements To Us Through Our Contact Us Page

OR Email to info@wjprototypes.com

Multi-material printers deploy separate reservoirs of photopolymers or resins that jet or cure layer by layer. In PolyJet systems, print heads selectively deposit droplets of rigid, rubber-like and transparent photopolymers that are cured instantly by UV lamps. The simultaneous deposition of these “digital materials” creates seamless transitions—such as stiff mounting bosses directly joined to flexible overmolds—within a single build cycle. This integration removes manual assembly steps and prepares prototypes for immediate testing.

These benefits accelerate validation workflows and establish production-ready prototypes faster. Understanding specific material characteristics then guides deeper optimization for end-use parts.

Multi-material 3D printing in China offers significant advantages in product development, including design freedom, functional integration, and efficiency gains. These benefits allow for complex geometries, the embedding of functional elements, and reduced assembly time, ultimately accelerating validation workflows and leading to production-ready prototypes more quickly.

RELATED ARTICLE: Transform Your Business with On-Demand 3D Printing Services

As mentioned above, Multi-material printing is used across various industries, including aerospace, medical, automotive, and consumer electronics. In aerospace, it creates lightweight components with vibration dampening. In medical, it enables patient-specific models. In automotive and consumer electronics, it streamlines functional testing and accelerates design approval.

Applications of Additive Manufacturing in Various Industries

This journal article provides examples of how multi-material printing is used in different industries, supporting the article's claims about industry-specific applications.

Chinese Multi-material 3d printing pivots on two dominant processes—PolyJet and stereolithography (SLA)—each offering unique deposition and curing mechanisms optimized for composite builds.

PolyJet and SLA are the two dominant technologies used in multi-material 3d printing, each with unique mechanisms for material deposition and curing. PolyJet uses multiple print heads to deposit photopolymer droplets, while SLA uses a UV laser to cure photopolymer resin layers. These differences impact the resolution, material palette, and typical applications of each technology.

PolyJet 3D printing propels photopolymer droplets from multiple print heads, depositing rigid, rubber-like and colored resins in micron-thin layers. A UV lamp immediately cures each droplet, fusing materials into seamless “digital composites.” This mechanism achieves fine feature resolution down to 14 µm and blends up to six materials in a single run, supporting prototypes with integrated hinges, gaskets and color-coded features.

SLA uses a UV laser to selectively cure photopolymer resin vat layers, delivering exceptional accuracy and surface finish. By swapping vats or using maskless lithography, SLA systems can produce parts that combine clear, rigid and flexible resins in complex assemblies. This precision supports transparent windows, fluidic channels and rigid frames within one build. Learn more about our SLA capabilities on our SLA 3D printing in China page.

We Are Happy To Help You! - Serving Clients Worldwide From China - Dedicated Project Manager.

No MOQ | Quality & Precision | Fast Turnaround | Rapid Prototypes | Low-Volume To Mass Production | Global Delivery

Talk To Our Certified Engineers. Send Your Requirements To Us Through Our Contact Us Page

OR Email to info@wjprototypes.com

| Technology | Material Palette | Resolution | Typical Applications |

|---|---|---|---|

| PolyJet | Rigid, rubber, transparent, color blends | 14 µm | Overmolds, soft-touch grips, color prototypes |

| SLA | Clear resins, rigid photopolymers, flexible resins | 25–50 µm | Fluidic channels, transparent lenses, rigid frames |

PolyJet excels at intricate multi-material blends and rapid color prototypes, while SLA offers superior surface finish and optical clarity. Selecting the right process depends on the required tolerance, finish and material performance.

Prototyping efficacy hinges on selecting materials whose attributes align with functional requirements. Common categories include elastomers, rigid photopolymers and clear resins.

Used in processes like Selective Laser Melting (SLM) or Direct Metal Laser Sintering (DMLS), these enable high-strength, heat-resistant builds:

Performance Snapshot (multi-material structure context):

| Material | Density (g/cm³) | Tensile Strength (MPa) | Young’s Modulus (GPa) | Thermal Conductivity (W/mK) | Corrosion Resistance |

|---|---|---|---|---|---|

| AlSi10Mg | 2.68 | 400 | 70 | 170 | Good |

| 316L SS | 7.99 | 580 | 193 | 16 | Excellent |

| Inconel 718 | 8.19 | 1100 | 211 | 11 | Excellent |

| Ti-6Al-4V | 4.43 | 900 | 120 | 7 | Excellent |

| CoCrMo | 8.29 | 1000 | 210 | 14 | Excellent |

| Maraging Steel | 8.0 | 2000 | 185 | 14 | Good |

| Copper | 8.96 | 210 | 130 | 400 | Poor |

These are widely used for prototypes, functional parts, and flexible components:

Blending base materials with reinforcing agents enhances strength, stiffness, and thermal/electrical performance:

Used in SLA, DLP, or binder-jetting—ideal for detailed and specialized parts:

Agilus30 is a rubber-like photopolymer with Shore A 30 durometer, offering high tear strength and 180 – 330% elongation at break. It supports dynamic overmolds, living hinges and gaskets, maintaining flexibility at temperatures from –20 °C to 80 °C. Designers choose Agilus30 for prototypes requiring repeated flexing or realistic soft-touch surfaces.

Below is an overview of common multi-material photopolymers:

| Entity | Attribute | Value |

|---|---|---|

| VeroWhitePlus | Rigidity | Shore D 83, tensile strength 50 MPa |

| VeroClear | Transparency | > 85 % light transmission, surface finish < 20 µin |

| Agilus30 | Flexibility | Shore A 30, elongation at break 300 % |

| Digital ABS | Impact Resistance | ABS-like strength, heat deflection up to 85 °C |

| DurusWhite | Durability | High fatigue resistance, suited for snap-fit designs |

These materials integrate seamlessly in PolyJet and SLA systems, allowing designers to tailor each section’s performance without post-processing.

Material selection directly influences part stiffness, wear resistance and aesthetic qualities. Rigid photopolymers deliver structural fidelity but lack shock absorption, whereas elastomers enable dynamic movement but reduce load-bearing capacity. Hybrid parts—such as a rigid handle with rubberized grip—combine these attributes into one print, eliminating manual adhesive operations and ensuring consistent assembly quality from prototype through low-volume production.

ALSO READ: Mastering the Art of Selecting a Rapid Prototyping Process

Integrating multiple materials in a single build not only enhances functionality but also streamlines manufacturing workflows, driving down both time and expense.

By fabricating assemblies with embedded seals, hinges and shock absorbers, designers can perform form, fit and function tests immediately. This reduces round-trip cycles between design and physical testing, enabling DFM engineers to validate complex parts without waiting for sub-component delivery. Rapid iteration ensures critical feedback occurs earlier in the development process.

Single-build multi-material parts eliminate secondary fastening, bonding and manual insertion of gaskets or springs. This consolidation cuts assembly labor by up to 60% and removes potential failure points caused by misalignment or adhesive degradation, ensuring prototypes more closely mimic final production assemblies.

For low-volume end-use parts, combining material zones into one print reduces tooling costs and lead times. Small batches of customized components—such as wear pads with integrated elastomeric backing—can be produced on demand with minimal setup, offering cost parity with injection molding for volumes under 500 units.

Aerospace engineers use multi-material printing to produce lightweight brackets with built-in vibration dampeners, reducing part count and total mass. Complex geometries—such as fluidic connectors with rigid flow channels and flexible sealing rings—are printed in one operation, ensuring leak-free performance in mission-critical environments.

In medical prototyping, combining biocompatible rigid resin for structural elements with flexible, tissue-simulating photopolymers creates models that surgeons can practice on and devices can be tested for wear inside simulated anatomical cavities. Transparent materials enable clear visualization of internal flow dynamics in catheter and implant designs.

Automotive suppliers fabricate sensor housings with integrated gaskets and wiring clips in a single print. In consumer electronics, rigid mounting frames merge with soft-touch enclosures and colored accents, producing concept models that require no post-assembly, accelerating design approval and marketing demonstrations.

Chinese companies combines industry-trusted equipment with rapid-turn service, delivering competitively priced, high-quality multi-material parts that integrate directly into your design cycle.

3D Printing comapnies in China employ systematic quality assurance protocols—including in-process monitoring, post-cure calibration and precision dimensional inspection—to guarantee that each zone meets its designated mechanical specification. This rigorous validation ensures prototypes are production-representative.

Request a customized quote today by visiting our contact page or uploading your CAD files through our online portal. Our team typically responds within 24 hours, helping you evaluate material options and project timelines to hit your development milestones.

Designers and engineers often ask the same critical questions when evaluating multi-material printing. Below are concise answers to help you compare processes, technologies and materials at a glance.

PolyJet jets micron-scale droplets of multiple photopolymers from separate nozzles and cures them instantly with UV light, blending materials layer by layer to form “digital composites” with seamless transitions.

Multi-material printing eliminates tooling and bonding steps, reducing lead times from weeks to days and lowering cost for low-volume production. It also enhances part complexity and functional testing compared to conventional machining or injection molding.

Laser-focused on integrating multiple material properties into a single build, multi-material 3D printing in China transforms prototyping and low-volume production by merging form, function and efficiency. By leveraging PolyJet’s digital composites and SLA’s optical precision, Chinese 3D printing companies empowers product designers and DFM engineers to accelerate development cycles, reduce assembly costs and deliver production-ready parts with unmatched speed. Unlock the full potential of additive manufacturing.

We Are Happy To Help You! - Serving Clients Worldwide From China - Dedicated Project Manager.

No MOQ | Quality & Precision | Fast Turnaround | Rapid Prototypes | Low-Volume To Mass Production | Global Delivery

Talk To Our Certified Engineers. Send Your Requirements To Us Through Our Contact Us Page

OR Email to info@wjprototypes.com