- Room 1807, Unit 9, Building 2, Shangxing Commercial Street, Shangde Road, Shangxing Community, Xinqiao Subdistrict, Bao'an District, Shenzhen City, China

Aerospace & UAV

WJ Prototypes is your 3D manufacturing partner from prototype to large scale production.

Consumer Electronics

New Product Introduction Solutions for Consumer Electronics.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Automotive

New Product Introduction Solutions for Automotive

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

WJ Prototypes offers vacuum casting from China to worldwide for customers who need high quality plastic parts without investing in expensive metal tooling. Our vacuum casting process is ideal for prototypes and small batch production where speed, cosmetic appearance, and predictable cost are important.

Thousands of components produced for customers in automotive, medical, robotics, consumer electronics, and industrial sectors.

Serving clients in the USA, Canada, Europe, Australia, and Asia with English speaking project engineers.

Quality management processes and IP protection measures to safeguard your designs.

Custom vacuum cast parts from around 10–1000+ pieces with flexible order quantities.

Master models, silicone molds, and vacuum cast parts can be produced in a matter of days, depending on part complexity and quantity.

Vacuum casting does not require hard steel tooling, making it a good option for bridge runs and pre production builds.

Silicone molds capture fine details and provide repeatable dimensions and surface finish for each casting.

Parts can be polished, painted, dyed, or clear coated to achieve near injection molded appearance for show models or functional testing.

Our engineers work with vacuum casting, CNC machining, and 3D printing daily and can help choose the best process for your project.

If you are searching for a vacuum casting supplier, factory, or manufacturer in China, WJ Prototypes can support you from quotation through to delivery. Our facilities in China combines vacuum casting with CNC machining and 3D printing to produce urethane cast parts that match your design and appearance requirements. We work directly with product designers, engineers, buyers, and founders who need reliable low volume manufacturing support in China.

You can send your CAD files and requirements, and our engineering team will review your design, suggest suitable materials, and provide an itemized quote.

You share your 3D files (STEP, IGES, STL) along with basic information such as material preference, color, quantity, and target surface finish. Our engineers check manufacturability and provide a quotation with estimated lead time.

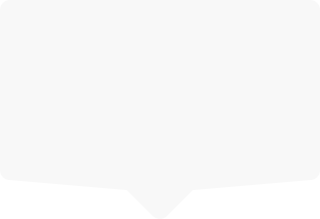

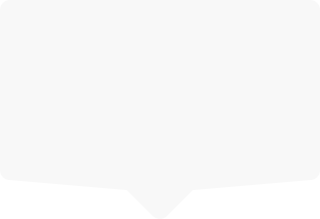

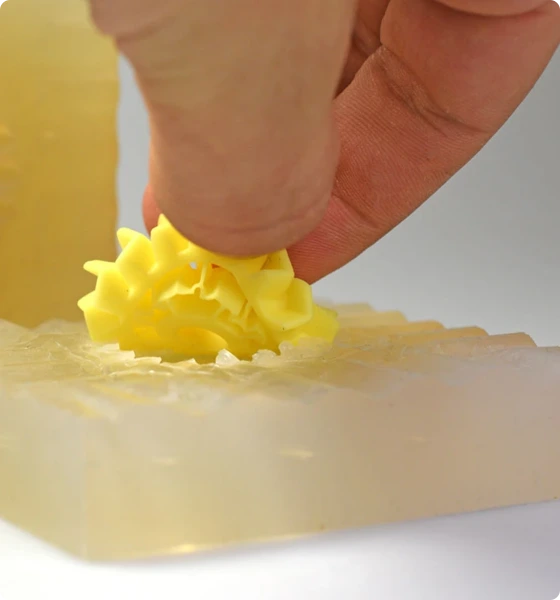

After approval, we create a precision master model using CNC machining or industrial 3D printing. This master is used to make silicone molds under vacuum, capturing fine details and the required geometry.

We pour liquid polyurethane into the silicone molds inside a vacuum chamber to minimize bubbles and voids. Once cured, parts are removed, trimmed, and finished based on your specification, such as polishing, painting, clear coating, or dyeing.

Each batch is inspected according to your requirements. Parts are carefully packed and shipped from our facility in China to your location, with tracking information shared after dispatch.

Vacuum casting uses polyurethane and similar casting resins to simulate common engineering plastics. We offer several “ like” material families to match the mechanical and cosmetic needs of your parts, along with multiple surface finishing options.

Other urethane systems, including clear resins, rubber like materials, and higher temperature options, may be available depending on your needs. Our team can recommend specific choices when we review your project.

Not sure which material or finish fits your design? Mention your requirements in the quote form and our engineers will make recommendations.

Vacuum casting is a good fit when you need realistic plastic parts in small to medium quantities without building full production tooling. It works well between early prototyping and full scale injection molding.

Appearance models for design reviews, presentations, and customer demonstrations.

Functional prototypes for fit, assembly, and limited performance testing.

Small batch pre production runs before committing to injection mold tooling.

Low volume end use parts where traditional tooling cost would be difficult to justify.

Automotive interior and exterior components such as covers, handles, and housings.

Medical and laboratory device housings and test fixtures.

Consumer electronics and smart home product enclosures.

Robotics, automation, and industrial equipment components.

Share your next project with us to see if vacuum casting is the right process or if another manufacturing option would be better.

Send your CAD files and basic requirements and our team will provide a vacuum casting quote, estimated lead time, and suggestions on materials and finishing.

Dorothy

Buyer at Leading Energy company

WJ Prototypes is Great!

“We’re glad we recently added WJ Prototypes to our AVL. You guys are always quick and friendly and all the Machining jobs we have sent have gone smoothly!”

Thomas

Engineer at Robotics Company

Our No.1 source for CNC parts

“We had a time sensitive Sheet Metal enclosure with fairly strict cosmetic requirements. WJ Prototypes came through for us and the parts looked great. The full build turned some heads at our Trade Show!”

Marc

Buyer at Electric Car Company

Great prices, lead times, and quality of work

“You guys are one of the easiest job shops I’ve worked with the last 10 years. You are responsive and competitive. We’ve appreciated the awesome work!”