- Room 1807, Unit 9, Building 2, Shangxing Commercial Street, Shangde Road, Shangxing Community, Xinqiao Subdistrict, Bao'an District, Shenzhen City, China

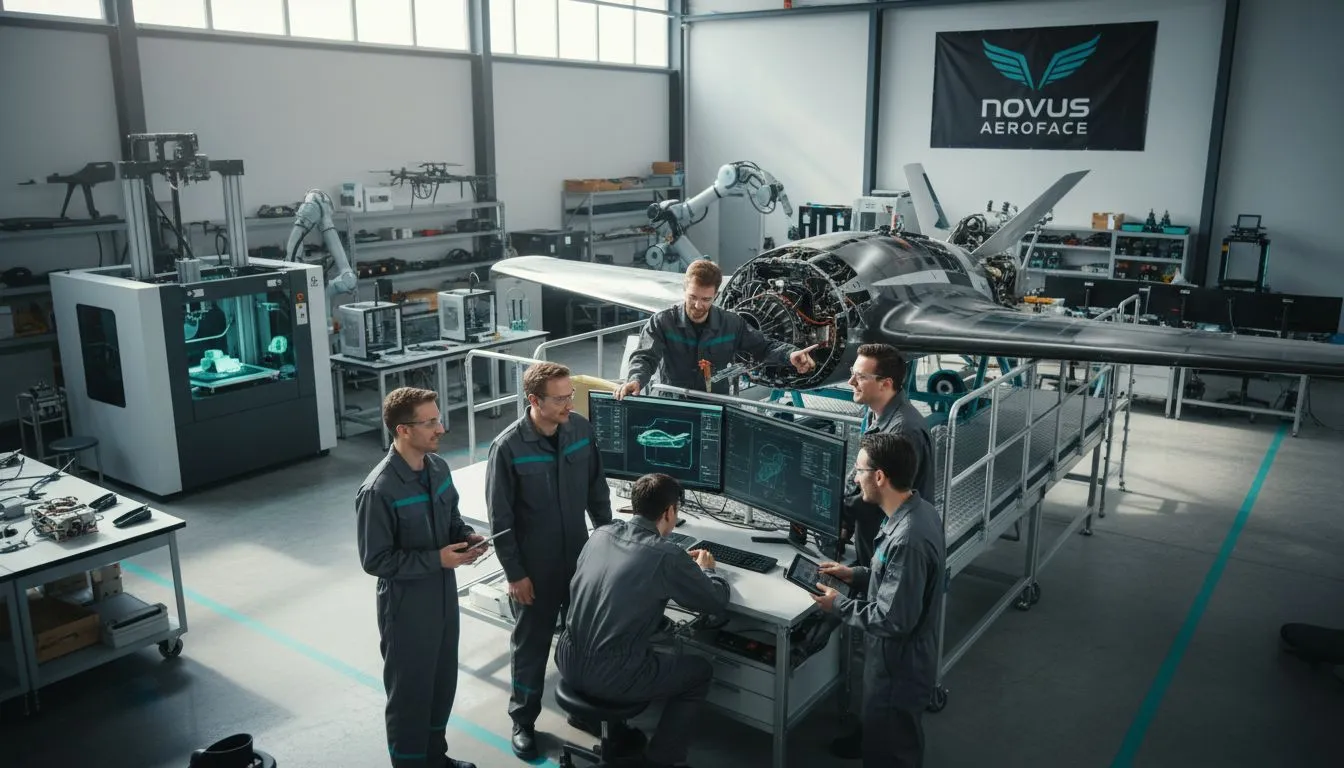

Aerospace & UAV

WJ Prototypes is your 3D manufacturing partner from prototype to large scale production.

Consumer Electronics

New Product Introduction Solutions for Consumer Electronics.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Automotive

New Product Introduction Solutions for Automotive

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

Aerospace projects can burn through millions before a single part ever takes flight. Precision is critical, yet even the most advanced computer models cannot catch every potential flaw. That is why prototyping stands as the backbone of aerospace engineering, transforming ideas into real-world solutions and helping to reduce costly design errors by up to 50 percent. By exploring how engineers turn concepts into testable models, this guide reveals the crucial steps that bring revolutionary aircraft from blueprint to reality.

| Point | Details |

|---|---|

| Prototyping Importance | Prototyping is essential in aerospace engineering for validating design concepts and mitigating risks before production. |

| Methodologies and Technologies | Modern prototyping utilizes digital, physical, and hybrid methods, integrating computational power with precision manufacturing. |

| Material Selection | Choosing the right materials is crucial, balancing performance requirements like strength-to-weight ratio and resistance to extreme conditions. |

| Quality Assurance | Rigorous quality assurance and regulatory compliance are vital, focusing on documentation, testing protocols, and adherence to international standards. |

Prototyping represents a pivotal engineering methodology specifically designed to transform abstract design concepts into tangible, testable models within the aerospace industry. According to TWI Global, prototyping involves "creating preliminary models of products or systems to test and refine concepts before final production."

In aerospace engineering, prototyping is far more than a simple preliminary sketch or mock-up. Atech Sland emphasises that it allows engineers to "simulate various scenarios and conditions, assessing how aircraft systems and components perform under stress, thereby identifying and mitigating potential risks before they become major issues."

The prototyping process in aerospace encompasses several critical objectives:

Precision engineering demands rigorous validation, and prototyping serves as the primary mechanism for engineers to systematically deconstruct, analyse, and refine aerospace designs before significant financial investment. By creating scaled models, computational simulations, and functional prototypes, aerospace engineers can predict potential challenges, optimize component interactions, and ensure ultimate safety and reliability.

Understanding prototyping requires recognising it as an iterative, dynamic process that bridges theoretical design and practical implementation. It transforms conceptual blueprints into robust, testable models that can withstand the extreme conditions inherent in aerospace applications.

For more insights into this fascinating process, review our guide on rapid prototyping best practices to understand how top engineering teams approach prototype development.

Modern aerospace engineering employs a diverse range of prototyping methods that enable comprehensive design exploration and validation. En Wikipedia highlights that digital prototyping allows "virtual exploration of complete products before physical manufacturing, enabling design, iteration, optimization, validation, and visualization throughout the product development process."

These prototyping technologies can be broadly categorised into several key approaches:

En Wikipedia emphasises that agile tooling plays a crucial role in this process, involving "designing and fabricating manufacturing-related tools like dies, molds, and fixtures using advanced manufacturing technologies to maximize performance, minimize time and cost, and expedite prototyping."

Advanced aerospace prototyping increasingly relies on sophisticated technologies that merge computational power with precision manufacturing.

These methods allow engineers to create increasingly complex and accurate representations of proposed designs, reducing development time and mitigating potential risks before full-scale production.

For a comprehensive understanding of selecting the right prototyping approach, explore our guide on choosing rapid prototyping processes.

Material selection represents a critical engineering challenge in aerospace prototyping, where every gram and molecular characteristic can dramatically influence aircraft performance and safety. En Wikipedia highlights the significance of advanced materials like carbon-fiber reinforced polymers (CFRPs), which are "extensively used in aerospace for their high strength-to-weight ratio," contributing to groundbreaking designs in aircraft such as the Airbus A350 XWB and Boeing 787 Dreamliner.

Key performance requirements for aerospace materials encompass several crucial dimensions:

Engineers must meticulously evaluate material properties through comprehensive testing protocols. En Wikipedia illustrates this precision with techniques like friction stir welding, which enables "joining materials like aluminum alloys, ensuring structural integrity and performance in components such as rocket fuel tanks and aircraft fuselages."

The selection process involves complex trade-offs between multiple performance parameters. Lightweight composites, advanced metal alloys, and hybrid materials are continuously developed to meet increasingly demanding aerospace engineering standards. These materials must withstand extreme environmental conditions while maintaining structural integrity and operational reliability.

To gain deeper insights into material selection strategies, explore our comprehensive guide on CNC machining materials, which provides detailed perspectives on material engineering for precision aerospace applications.

Quality assurance in aerospace prototyping represents a complex and critical process that demands unprecedented precision and systematic validation. ArXiv Research highlights an innovative approach called FREPA, which is "an automated and formal approach to requirement modeling and analysis in the aircraft control domain, facilitating systematic engineering processes to ensure quality and compliance in aerospace systems."

Critical components of aerospace quality assurance include:

ArXiv Research emphasises the importance of knowledge-based aerospace engineering, which involves "systematic literature reviews and knowledge management practices to enhance design processes, collaboration, and adherence to regulatory standards in the aerospace industry."

Regulatory compliance demands meticulous attention to multiple global standards, including FAA, EASA, and ISO requirements. Engineers must develop comprehensive quality management systems that not only meet but anticipate potential regulatory challenges, ensuring that every prototype undergoes exhaustive validation before advancing to subsequent development stages.

The intersection of technological innovation and regulatory compliance creates a complex landscape where precision, documentation, and systematic validation become paramount. Successful aerospace prototyping requires a holistic approach that balances cutting-edge design with unwavering commitment to safety and performance standards.

Risk management in aerospace prototyping demands a sophisticated approach that balances technological innovation with financial constraints. ArXiv Research introduces an advanced methodology called Hyper Space Exploration, which combines "virtual prototyping and statistical learning to identify optimal system designs, manage risks, and reduce development time and costs in complex aerospace environments."

Key strategic approaches for managing prototype development include:

Military Aerospace emphasises that "virtual prototyping allows for design and testing of aircraft systems in a virtual environment, reducing the need for physical prototypes, thereby decreasing costs, lead times, and associated risks."

Successful risk management requires a multi-dimensional approach that integrates advanced computational modeling, financial forecasting, and iterative design strategies. Engineers must develop flexible frameworks that can rapidly adapt to changing technological landscapes while maintaining stringent performance and safety standards.

To gain deeper insights into managing prototype development costs, explore our guide on cutting costs for CNC machining parts, which provides practical strategies for optimizing your engineering budget.

Aerospace production and prototyping represent two interconnected yet distinctly different stages of engineering development. En Wikipedia highlights that Rapid Control Prototyping (RCP) enables "quick evaluation of control systems, allowing for early identification and correction of potential issues before transitioning to full-scale aerospace production."

Key differences between prototyping and production include:

En Wikipedia emphasises that digital prototyping "facilitates the assessment of product designs digitally, reducing the number of physical prototypes needed and streamlining the transition from design to production in aerospace engineering."

The transition from prototype to production requires meticulous engineering strategies that bridge conceptual design and manufacturing realities. While prototypes serve as experimental models to validate design concepts, production involves creating standardised, repeatable systems that meet exacting aerospace industry standards.

To gain deeper insights into aerospace prototyping technologies, explore our comprehensive guide on 3D printing in aerospace applications, which provides a detailed perspective on cutting-edge manufacturing techniques.

Prototyping in aerospace demands unwavering attention to detail, rigorous quality assurance, and cutting-edge manufacturing techniques to overcome challenges such as material selection, risk management, and rapid iteration. If you are aiming to transform complex aerospace designs into reliable, tested prototypes that meet the highest standards, understanding the intricacies of digital and physical prototyping is essential. Pain points like minimising lead times, controlling costs, and ensuring compliance with stringent regulations can feel overwhelming without the right partner.

At WJ Prototypes, we specialise in turning your aerospace engineering concepts into reality with precision and speed. Our advanced suite of services including CNC machining, 3D printing methods such as SLA and SLS, and vacuum casting are tailored to meet the demanding performance and safety requirements highlighted in aerospace development. Benefit from fast, cost-effective solutions that reduce your prototyping risks and accelerate your innovation cycle. Ready to experience a seamless transition from design to high-quality prototype? Discover more about our expert capabilities in aerospace rapid prototyping and fabrication at WJ Prototypes, and take the first step towards bringing your aerospace projects to life today.

Prototyping in aerospace engineering is crucial for transforming design concepts into tangible, testable models. It helps validate complex designs, evaluate structural integrity, reduce manufacturing risks, and ensure safety before full-scale production.

The main prototyping methods in aerospace include digital prototyping, such as CAD modeling and virtual simulations, physical prototyping using techniques like 3D printing and CNC machining, and hybrid approaches that combine both digital and physical modeling for iterative design refinement.

Material selection is vital because every gram and material property affects aircraft performance and safety. Aerospace materials must meet stringent requirements for strength-to-weight ratio, temperature resistance, and fatigue resilience to ensure functionality in extreme conditions.

Quality assurance ensures that aerospace prototypes meet international safety standards and undergo thorough testing and documentation. It is essential for systematic validation and compliance, ultimately ensuring the safety and performance of aerospace systems.