- Room 1807, Unit 9, Building 2, Shangxing Commercial Street, Shangde Road, Shangxing Community, Xinqiao Subdistrict, Bao'an District, Shenzhen City, China

Aerospace & UAV

WJ Prototypes is your 3D manufacturing partner from prototype to large scale production.

Consumer Electronics

New Product Introduction Solutions for Consumer Electronics.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Automotive

New Product Introduction Solutions for Automotive

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

Most manufacturing engineers in the aerospace and automotive sectors across the United States and Europe face intense pressure to deliver precision prototypes at competitive costs. With over 85% of global plastic components produced using injection moulding technologies, choosing the right partner can determine your project's success. Comparing British expertise with American and European manufacturing hubs, this article uncovers practical insights on cost efficiency and precision, empowering you to make the most informed decision for your next prototype run.

| Point | Details |

|---|---|

| Injection Moulding Precision | Injection moulding is a highly efficient method for producing intricate plastic parts with exceptional accuracy and repeatability, essential for high-volume manufacturing. |

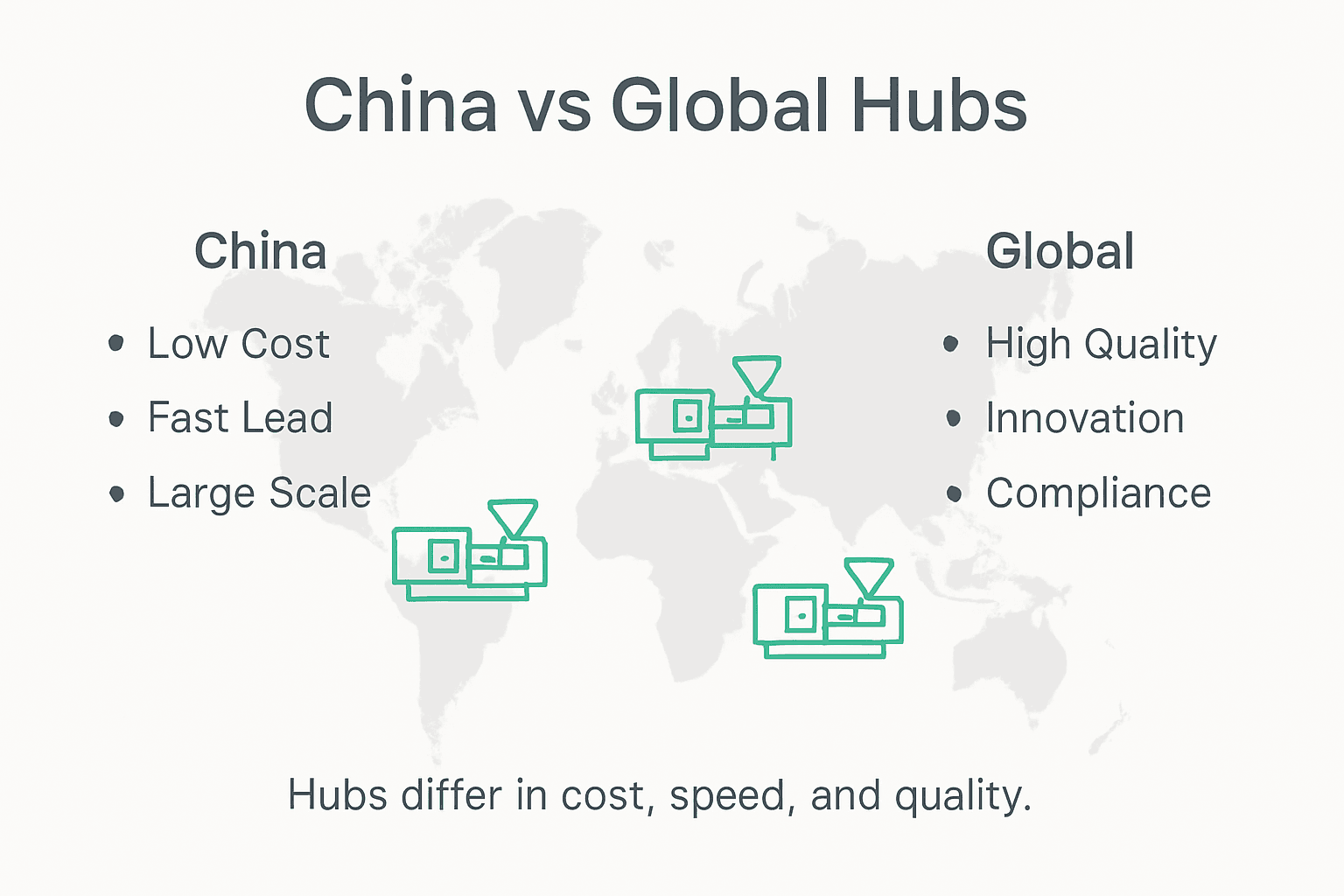

| Global Manufacturing Hub Capabilities | Different manufacturing hubs excel in specific areas such as automation in China, precision in Germany, innovation in the United States, and reliability in Japan, influencing production outcomes. |

| Importance of Quality Certifications | Adhering to international quality standards such as ISO 9001 and ISO 13485 is crucial for manufacturers to ensure consistent quality and regulatory compliance across markets. |

| Technological Adaptation | Successful manufacturing hubs integrate emerging technologies and continuously innovate to improve efficiency, reduce lead times, and enhance overall production quality. |

Injection moulding represents a sophisticated manufacturing technique that enables precise production of complex plastic components through a carefully controlled thermal process. Injection molding utilises advanced manufacturing principles where molten polymer material is systematically injected into precision-engineered moulds, transforming raw materials into functional parts with remarkable accuracy.

The core mechanism involves heating synthetic polymers until they reach a molten state, then applying significant pressure to force the material into a meticulously designed mould cavity. This process enables manufacturers to create intricate parts with complex geometries, using parameters such as injection pressure, mould material, and cooling channel configurations to control final product characteristics. The technique is particularly prevalent in industries requiring high-volume, consistent production of plastic components.

Key characteristics of injection moulding include its exceptional repeatability, ability to produce parts with tight dimensional tolerances, and capacity to work with numerous thermoplastic and thermoset materials. Manufacturers can achieve remarkable detail and surface finish, making this process integral for producing everything from microscopic medical device components to large automotive parts.

Pro tip:When selecting an injection moulding service, carefully evaluate their material compatibility, machinery precision, and quality control processes to ensure optimal manufacturing outcomes.

Global manufacturing hubs are transforming industrial production through strategic technological innovations, driving unprecedented advancements in manufacturing capabilities across diverse geographical regions. These technological centres distinguish themselves by addressing complex production challenges through targeted strategies that blend cutting-edge engineering, efficient processes, and adaptive technological solutions.

Modern manufacturing hubs are characterised by their ability to integrate advanced technologies such as automation, artificial intelligence, and sustainable production methods. Injection moulding technologies have revolutionised global manufacturing by enabling precise, high-volume production of intricate components across multiple industrial sectors, with each regional hub developing unique specialisations and competitive advantages.

Key differentiators among global manufacturing hubs include their technological infrastructure, workforce expertise, regulatory environments, and commitment to innovation. Countries like China, Germany, the United States, and Japan have established themselves as leaders by investing heavily in research and development, maintaining stringent quality control standards, and continuously evolving their manufacturing ecosystems to remain competitive in the global marketplace.

The most successful manufacturing hubs demonstrate remarkable adaptability, integrating emerging technologies while maintaining cost-effectiveness and high-quality production standards. They focus on developing specialised ecosystems that support advanced manufacturing, attract skilled talent, and foster collaborative research and development initiatives.

Here is a summary highlighting how key global manufacturing hubs differ in their injection moulding strengths:

| Manufacturing Hub | Technological Focus | Workforce Specialisation | Main Industry Advantages |

|---|---|---|---|

| China | Advanced automation, rapid scaling | Large, technically trained pool | Cost-effective, high-volume production |

| Germany | Precision engineering, R&D | Skilled engineers, apprenticeships | Superior quality, complex parts |

| United States | Innovation, adaptive tech | Multidisciplinary teams | Flexible, advanced prototyping |

| Japan | Process control, robotics | Emphasis on precision | High-quality, reliable output |

Pro tip:When evaluating global manufacturing hubs, assess their technological capabilities, workforce skills, innovation potential, and alignment with your specific production requirements.

Manufacturing cost comparisons between global hubs reveal nuanced differences that extend beyond simple price per unit. Understanding international manufacturing dynamics requires examining lead times and shipping complexities associated with different regional production centres, particularly when evaluating injection moulding services across diverse geographical markets.

Chinese manufacturing hubs have consistently demonstrated competitive advantages in cost structures, with significant reductions in production expenses compared to Western manufacturing regions. Key metrics include labour costs, raw material pricing, technological infrastructure, and operational efficiency. These factors contribute to China's ability to offer substantially lower per-unit manufacturing costs while maintaining robust quality standards across various industrial sectors.

Quality metrics in injection moulding services are increasingly sophisticated, involving comprehensive evaluations beyond traditional manufacturing parameters. Advanced manufacturing hubs now integrate precision measurement technologies, statistical process control, and real-time quality monitoring systems. These approaches enable manufacturers to achieve consistent tolerances, minimise defect rates, and ensure reproducible product performance across different production batches.

Lead times represent another critical comparative metric, with Chinese manufacturers often offering significantly compressed production schedules. Factors influencing lead times include technological infrastructure, workforce expertise, supply chain integration, and logistical capabilities. Successful global manufacturers differentiate themselves by optimising these interconnected variables to deliver high-quality components within increasingly compressed timeframes.

Pro tip:Conduct comprehensive due diligence by requesting detailed quality certifications, sample production runs, and historical performance data when evaluating international manufacturing partners.

Regulatory compliance in global manufacturing represents a complex landscape of international standards, technical requirements, and industry-specific protocols that manufacturers must navigate with precision. International manufacturing regulations demand comprehensive understanding of tariff implications and cross-border compliance mechanisms, particularly when sourcing injection moulding services across different geographical regions.

Injection moulding manufacturers must adhere to multiple certification frameworks, including ISO 9001 for quality management, ISO 13485 for medical device manufacturing, and industry-specific standards like IATF 16949 for automotive components. These certifications ensure rigorous quality control, consistent production processes, and systematic approach to manufacturing that transcends geographical boundaries. Each certification requires extensive documentation, regular audits, and demonstrable commitment to continuous improvement and operational excellence.

Global manufacturing hubs differentiate themselves through their ability to meet and exceed international regulatory requirements. Chinese manufacturers have made significant strides in obtaining international certifications, investing heavily in quality management systems, technological infrastructure, and workforce training. This approach enables them to compete effectively in global markets by demonstrating compliance with stringent international standards and meeting the increasingly complex requirements of multinational corporations.

The certification process involves comprehensive evaluation of manufacturing capabilities, including material traceability, process documentation, quality management systems, and consistent performance metrics. Manufacturers must provide detailed evidence of their ability to maintain precise tolerances, implement robust quality control mechanisms, and ensure reproducible production outcomes across diverse manufacturing environments.

Below is a table illustrating essential certification frameworks and what each ensures in injection moulding:

| Certification | Focus Area | Business Benefit |

|---|---|---|

| ISO 9001 | Quality management systems | Ensures consistent quality processes |

| ISO 13485 | Medical device manufacturing | Guarantees medical-grade product standards |

| IATF 16949 | Automotive component quality | Meets global automotive industry requirements |

| CE Marking | European market compliance | Enables legal sale within Europe |

Pro tip:Request comprehensive certification documentation and conduct thorough third-party audits to validate a manufacturer's regulatory compliance and quality management capabilities.

Statistical quality control methodologies have transformed precision engineering across global manufacturing hubs, demonstrating the profound impact of systematic approach to manufacturing excellence. These case studies reveal how innovative engineering strategies can dramatically improve product performance, efficiency, and manufacturing reliability.

In one exemplary instance, a Taiwanese electronics manufacturer employed advanced Six Sigma techniques to revolutionise laptop battery case production. By meticulously optimising injection speed and cooling parameters, the team achieved remarkable improvements in manufacturing precision. Precision injection moulding techniques in China have similarly demonstrated extraordinary capabilities in complex component manufacturing, highlighting the technological sophistication of Asian manufacturing ecosystems.

Another compelling case study involves an automotive components manufacturer that leveraged advanced computational modelling and real-time monitoring technologies to enhance injection moulding processes. By implementing sophisticated quality control mechanisms, they reduced defect rates by over 67%, significantly improving overall production efficiency and product reliability. These advancements underscore the critical role of technological innovation in contemporary manufacturing environments.

Global manufacturing hubs are increasingly distinguishing themselves through their ability to integrate cutting-edge technologies, data-driven quality control methods, and precision engineering techniques. The most successful organisations demonstrate a holistic approach that combines advanced technical infrastructure, skilled workforce development, and continuous process improvement strategies.

Pro tip: Evaluate potential manufacturing partners by examining their historical performance data, technological capabilities, and demonstrated commitment to continuous technological innovation.

Navigating the complexities of global injection moulding hubs requires more than just cost considerations. The article highlights critical challenges such as maintaining strict quality metrics, achieving fast lead times, and ensuring comprehensive regulatory compliance. If you are striving to balance precise engineering with cost-effectiveness, the need for advanced technological infrastructure and certified quality management systems becomes paramount.

At WJ Prototypes, we understand these pain points and offer tailored solutions through our state-of-the-art injection moulding capabilities based in China. Our ISO-certified manufacturing processes guarantee exceptional repeatability and precision, supporting industries from aerospace to medical devices with rapid prototyping and low-volume production runs. Leveraging the latest automation and quality control methods, we deliver high-quality components with swift turnaround times and transparent compliance documentation. Explore how our expertise aligns perfectly with your manufacturing goals by visiting our Injection Moulding Service page.

Take the next step towards optimising your production by partnering with a trusted global manufacturer who combines innovation, skilled craftsmanship, and competitive pricing. Discover more about our comprehensive offerings and receive an instant quote today at WJ Prototypes. Don’t let logistical challenges and quality uncertainties hold back your product development journey. Act now and experience manufacturing excellence tailored to your unique requirements.

Injection moulding is a manufacturing technique that involves heating synthetic polymers until they are molten, then injecting this material under pressure into precision-engineered moulds to produce complex plastic components. This process allows for high-volume, accurate production of intricate parts.

Injection moulding offers exceptional repeatability, tight dimensional tolerances, and the ability to create detailed parts from various thermoplastic and thermoset materials. It is particularly efficient for high-volume production, making it a preferred choice for industries needing consistent output.

Manufacturing costs differ based on factors such as labour costs, material prices, and operational efficiency. Lead times can also vary, with certain hubs being able to offer shorter production schedules due to advanced technological infrastructure and efficient supply chains.

Injection moulding manufacturers should comply with various certification standards, including ISO 9001 for quality management, ISO 13485 for medical devices, and IATF 16949 for automotive components. These certifications help ensure quality control and consistent production processes.

Injection Molding Companies China - How to Choose the Best

Vacuum Casting in China Versus Global Quality Evaluation

USA Tariff Changes vs Manufacturing in China

What Is Injection Molding? A Complete Guide to Moulding Processes