- Room 1807, Unit 9, Building 2, Shangxing Commercial Street, Shangde Road, Shangxing Community, Xinqiao Subdistrict, Bao'an District, Shenzhen City, China

Aerospace & UAV

WJ Prototypes is your 3D manufacturing partner from prototype to large scale production.

Consumer Electronics

New Product Introduction Solutions for Consumer Electronics.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Automotive

New Product Introduction Solutions for Automotive

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

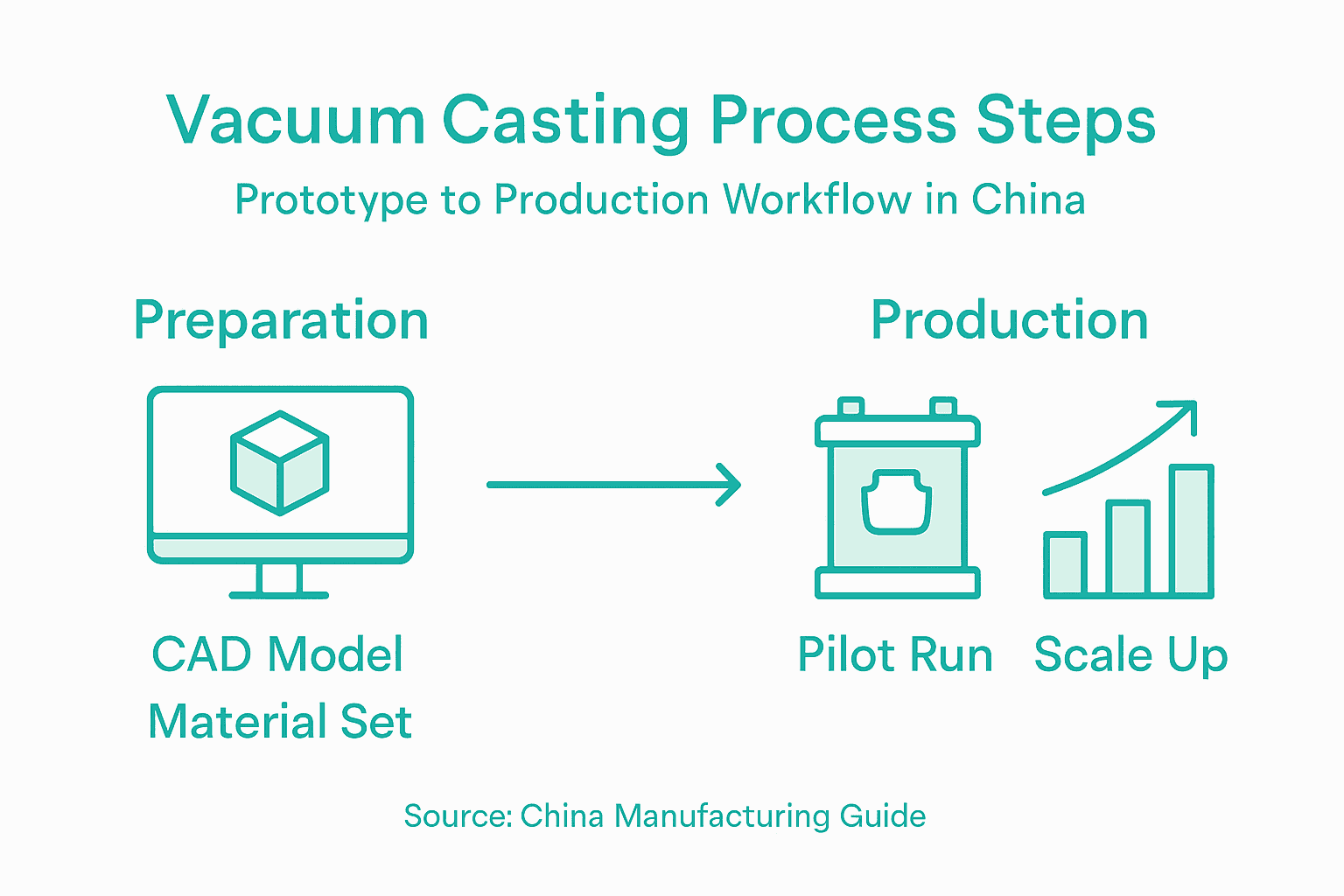

A single error in vacuum casting can cost british manufacturers thousands before production even begins. For product designers and engineers worldwide, especially those in competitive sectors, the journey from prototype to production demands both speed and accuracy. Optimizing each step not only preserves your budget but ensures your final part performs flawlessly. This guide delivers practical, proven strategies for making the shift smoother, with clear advice focused on common obstacles and technical considerations in modern vacuum casting.

| Key Insight | Explanation |

|---|---|

| 1. Assess Prototyping Requirements | Begin with a thorough analysis of design, material specifications, and functional expectations for effective vacuum casting. |

| 2. Prepare Accurate CAD Files | Create precise digital models that reflect all design details, ensuring effective material selection and consistency in manufacture. |

| 3. Choose the Right Partner | Evaluate potential vacuum casting manufacturers in China based on technical expertise, quality, and communication skills. |

| 4. Conduct Pilot Runs | Perform limited production tests to validate design and material choices while ensuring adherence to specified tolerances. |

| 5. Optimise Production Processes | Streamline workflows and standardise practices to enhance efficiency and scalability for full-scale vacuum casting production. |

Successfully transitioning from prototyping to production using vacuum casting requires strategic assessment of your manufacturing requirements. Your initial focus should involve understanding the specific design parameters, material specifications, and functional expectations for your proposed part.

Begin by conducting a comprehensive analysis of your prototype design. Engineers must carefully evaluate dimensional tolerances, geometric complexity, and surface finish requirements. Precise dimensional tolerances are crucial when determining whether vacuum casting represents the optimal manufacturing approach. Consider factors like part size, intricate details, and anticipated production volume to determine whether this method aligns with your project goals.

Carefully examine material compatibility and mechanical properties. Different vacuum casting materials offer varying performance characteristics suitable for specific applications. Some materials excel in thermal resistance, while others provide superior mechanical strength or aesthetic qualities. Consult technical specifications and conduct initial prototype testing to validate material selection and performance expectations.

Below is a comparison of common vacuum casting materials for prototype and production use:

| Material Type | Key Properties | Typical Applications |

|---|---|---|

| Polyurethane Resins | Good detail, strong, rigid | Functional prototypes, housings |

| Silicone Rubbers | Flexible, chemical resist. | Gaskets, seals, soft-touch parts |

| Epoxy Resins | Hard, heat resistant | High-strength components |

| ABS-like Resins | Durable, impact resistant | Mechanical parts, enclosures |

Expert Suggestion: Develop multiple prototype iterations using different material formulations to optimise your final production strategy.

Successfully preparing CAD files and material specifications is a critical step in transitioning your prototype to production using vacuum casting. Your objective is to create precise digital models that capture every intricate detail of your design while selecting materials that match your performance requirements.

Begin by refining your CAD model with meticulous attention to detail. Vacuum system design criteria.pdf) demand exceptional geometric accuracy. Remove unnecessary complexity while maintaining critical dimensional tolerances. Engineers should ensure wall thicknesses are consistent, draft angles are appropriate, and geometric features align perfectly with manufacturing constraints. Pay special attention to surface finishes and potential areas of stress concentration.

Next, select material specifications that complement your design requirements. Consider mechanical properties such as tensile strength, thermal resistance, and chemical compatibility. Different vacuum casting materials offer unique performance characteristics. Some provide superior impact resistance, while others excel in temperature stability or aesthetic qualities. Document your material selection process thoroughly, including rationale for each chosen specification.

Expert Suggestion: Develop digital simulations of your CAD model to validate design feasibility before final material selection and prototyping.

Selecting the right vacuum casting partner in China requires strategic evaluation and comprehensive research. Your goal is to identify a manufacturer that combines technical expertise, quality assurance, and reliable production capabilities for your specific project requirements.

Market entry strategies play a crucial role in identifying potential manufacturing partners. Begin by conducting thorough due diligence on potential vacuum casting providers. Examine their technical capabilities, equipment specifications, quality certifications, and previous project portfolios. Look for manufacturers with proven experience in your specific industry sector and demonstrated ability to handle complex geometric designs and precise material specifications.

Evaluate potential partners across multiple critical dimensions. Assess their manufacturing infrastructure, technological capabilities, quality control processes, and compliance with international standards. Request detailed documentation including ISO certifications, production capabilities, material compatibility reports, and sample project references. Consider factors such as communication effectiveness, responsiveness, pricing transparency, and ability to meet your specific production timelines. Pay particular attention to regional manufacturing specialisations and potential logistical advantages within different Chinese manufacturing hubs.

Here is a summary of key decision factors when selecting a vacuum casting partner in China:

| Evaluation Aspect | Why It Matters | What To Look For |

|---|---|---|

| Technical Expertise | Impacts quality and complexity handling | In-depth knowledge of advanced techniques |

| Certification & Standards | Ensures compliance and reliability | ISO certification, industry standards met |

| Communication | Facilitates smooth collaboration | Clear, prompt responses in English |

| Production Capabilities | Affects scalability and consistency | Adequate equipment and skilled workforce |

Expert Suggestion: Arrange site visits or request comprehensive video documentation of manufacturing facilities to validate a potential partner's actual capabilities.

Executing pilot runs represents a critical phase in transitioning your vacuum casting design from prototype to production. Your objective is to systematically validate design performance, material compatibility, and manufacturing repeatability before full-scale production.Verification and validation processes require meticulous planning and comprehensive testing protocols. Begin by producing a limited production batch using your finalised design and selected materials. Carefully document each manufacturing parameter including temperature settings, injection pressures, cooling times, and material mixture specifications. Conduct rigorous dimensional inspections to ensure each produced part meets your exact geometric tolerances and functional requirements.

Analyse pilot run results across multiple critical performance metrics. Evaluate mechanical properties such as tensile strength, impact resistance, and thermal stability. Perform destructive and non-destructive testing to identify potential weaknesses or inconsistencies in your design. Compare actual produced parts against your original CAD specifications, looking for variations in surface finish, structural integrity, and functional performance. Generate detailed statistical reports that quantify manufacturing consistency and highlight any potential areas requiring refinement.

Expert Suggestion: Maintain comprehensive documentation of every pilot run test result to support continuous improvement and regulatory compliance.

Transitioning from successful pilot runs to full production requires strategic process optimisation. Your goal is to develop a repeatable manufacturing workflow that maintains high quality while increasing production efficiency and reducing overall costs.

Precision engineering design principles are fundamental to successful manufacturing scalability. Begin by systematically mapping your current production workflow, identifying potential bottlenecks and inefficiencies. Analyse each manufacturing stage meticulously, looking for opportunities to standardise processes, reduce material waste, and minimise variability. Consider implementing statistical process control methods to monitor and maintain consistent product quality across larger production volumes.

Focus on developing robust manufacturing parameters that can be reliably replicated at scale. This involves fine tuning equipment settings, optimising material mixture ratios, and establishing precise temperature and pressure controls. Invest time in training production personnel to ensure they understand the critical parameters that influence part quality. Continuously collect and analyse production data to drive incremental improvements, creating a feedback loop that allows for ongoing process refinement and performance enhancement.

Expert Suggestion: Develop comprehensive standard operating procedures that capture every critical manufacturing parameter to ensure consistent quality across different production runs.

Successfully transitioning from prototype to production requires comprehensive financial and temporal planning. Your objective is to develop a precise, realistic roadmap that captures all potential expenses and production milestones associated with vacuum casting manufacturing.Vacuum system parameter calculations provide critical insights into developing accurate cost estimates. Begin by breaking down your production process into distinct phases, quantifying material costs, labour expenses, equipment utilisation, and overhead charges. Consider direct expenses such as raw material procurement, machine runtime, and personnel hours alongside indirect costs like quality control, facility maintenance, and potential rework expenses.

Create a comprehensive financial model that accounts for potential variability and risk factors. Develop multiple scenario projections considering best case, average case, and worst case production environments. Factor in potential supply chain disruptions, material price fluctuations, and technology upgrade requirements. Establish clear Key Performance Indicators that will help you track actual performance against your initial cost and timeline projections. Build sufficient contingency margins into your estimates to accommodate unexpected challenges while maintaining realistic budgetary constraints.

Expert Suggestion: Utilise computational spreadsheet models with dynamic calculation capabilities to enable rapid recalculation of financial projections as production parameters evolve.

Navigating the path from prototyping to full-scale production in vacuum casting requires precision, expert material selection, and reliable manufacturing partners. Common challenges in vacuum casting in China include ensuring dimensional accuracy, choosing the right materials, validating pilot runs, and optimising processes for scalable, cost-effective outcomes. At WJ Prototypes, we understand these crucial steps and the need for clear communication and quality assurance throughout.

Why struggle with complexity when you can partner with an ISO certified manufacturer experienced in vacuum casting and rapid prototyping? WJ Prototypes offers comprehensive solutions supported by advanced technologies and materials tailored to your project needs. With expertise spanning aerospace, automotive, medical, and more, we ensure your transition from prototype to production is fast, reliable, and economically sound.

Explore how WJ Prototypes can help you overcome the challenges of vacuum casting production by visiting our main site WJ Prototypes. Start by discussing your design and material specifications with our expert team to unlock your project’s full potential. For an instant quote and detailed service options, see our vacuum casting capabilities. Don’t wait to bring your ideas to life with precision and speed—contact us today and advance confidently from prototype to production.

Begin by evaluating your design parameters, material specifications, and functional expectations. Consider factors such as dimensional tolerances, geometric complexity, and material compatibility to ensure the vacuum casting method suits your project goals.

To prepare your CAD files, refine your model for geometric accuracy and maintain consistent wall thicknesses and draft angles. Remove unnecessary complexities, ensuring that every detail aligns with manufacturing constraints for optimal results.

Evaluate potential partners based on their technical expertise, quality certifications, and ability to meet your production needs. Look for manufacturers with proven experience in your industry and check for compliance with international standards to ensure reliability.

To validate your design, execute a limited production batch and conduct thorough inspections of dimensional accuracy and mechanical properties. Document each manufacturing parameter and analyse the results to identify any areas needing improvement before full-scale production.

Focus on mapping your production workflow to identify bottlenecks and inefficiencies. Standardise processes, monitor product quality, and continuously collect production data to refine your methods for better efficiency and cost savings.

Break down the production process into distinct phases, quantifying all costs associated with materials, labour, and overhead. Develop a financial model that accounts for variability, and create multiple scenario projections to prepare for potential challenges.

Guide To Vacuum Casting - Master Prototyping for Precision Parts

Why Choose Vacuum Casting: Everything You Need to Know

Vacuum Casting in China Versus Global Quality Evaluation

Vacuum Casting In China | Get A Quote For Vacuum Casting Services

Complete Guide to the Footwear Manufacturing Process – YDA UK