- Room 1807, Unit 9, Building 2, Shangxing Commercial Street, Shangde Road, Shangxing Community, Xinqiao Subdistrict, Bao'an District, Shenzhen City, China

Aerospace & UAV

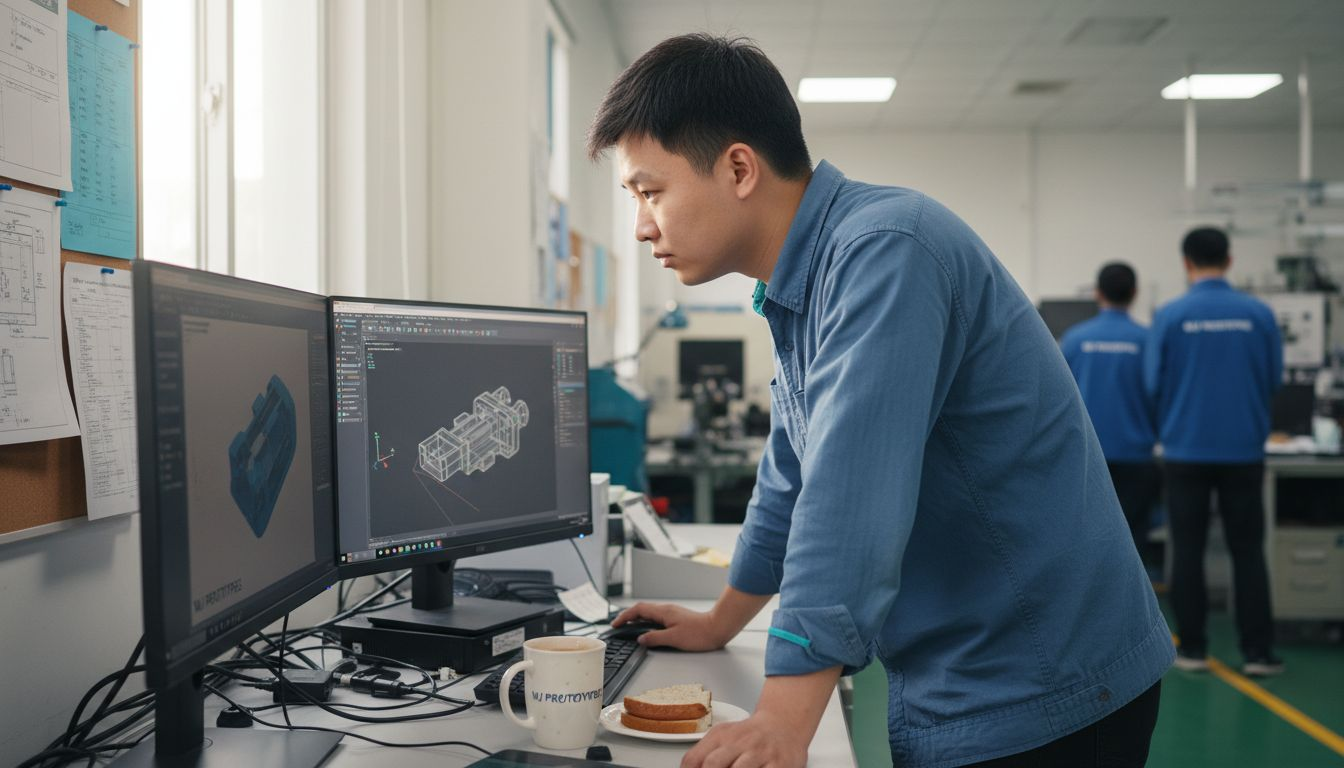

WJ Prototypes is your 3D manufacturing partner from prototype to large scale production.

Consumer Electronics

New Product Introduction Solutions for Consumer Electronics.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Automotive

New Product Introduction Solutions for Automotive

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

Most procurement managers know that poor CNC machining can derail even the best aerospace designs. With over 90 percent of british aerospace companies prioritising tight tolerances and reliable delivery for prototypes, the choice of supplier becomes a critical decision. China now stands out for advanced CNC services in precision prototyping and low-volume runs, offering access to multi-axis technologies and rigorous quality controls that meet strict industry demands.

| Point | Details |

|---|---|

| CNC Machining Versatility | CNC machining services cater to various industries, offering operations like milling, turning, drilling, and grinding for a diverse range of materials. |

| Technological Innovations | Advanced CNC technologies, including multi-axis machining and AI-integrated control systems, enhance flexibility and precision in manufacturing processes. |

| Material and Finish Importance | Selecting the right materials and appropriate surface finishes is crucial for optimising component performance and longevity. |

| Supplier Evaluation Criteria | When choosing a CNC supplier, focus on their technical capabilities, quality management practices, and transparent communication to ensure reliable outcomes. |

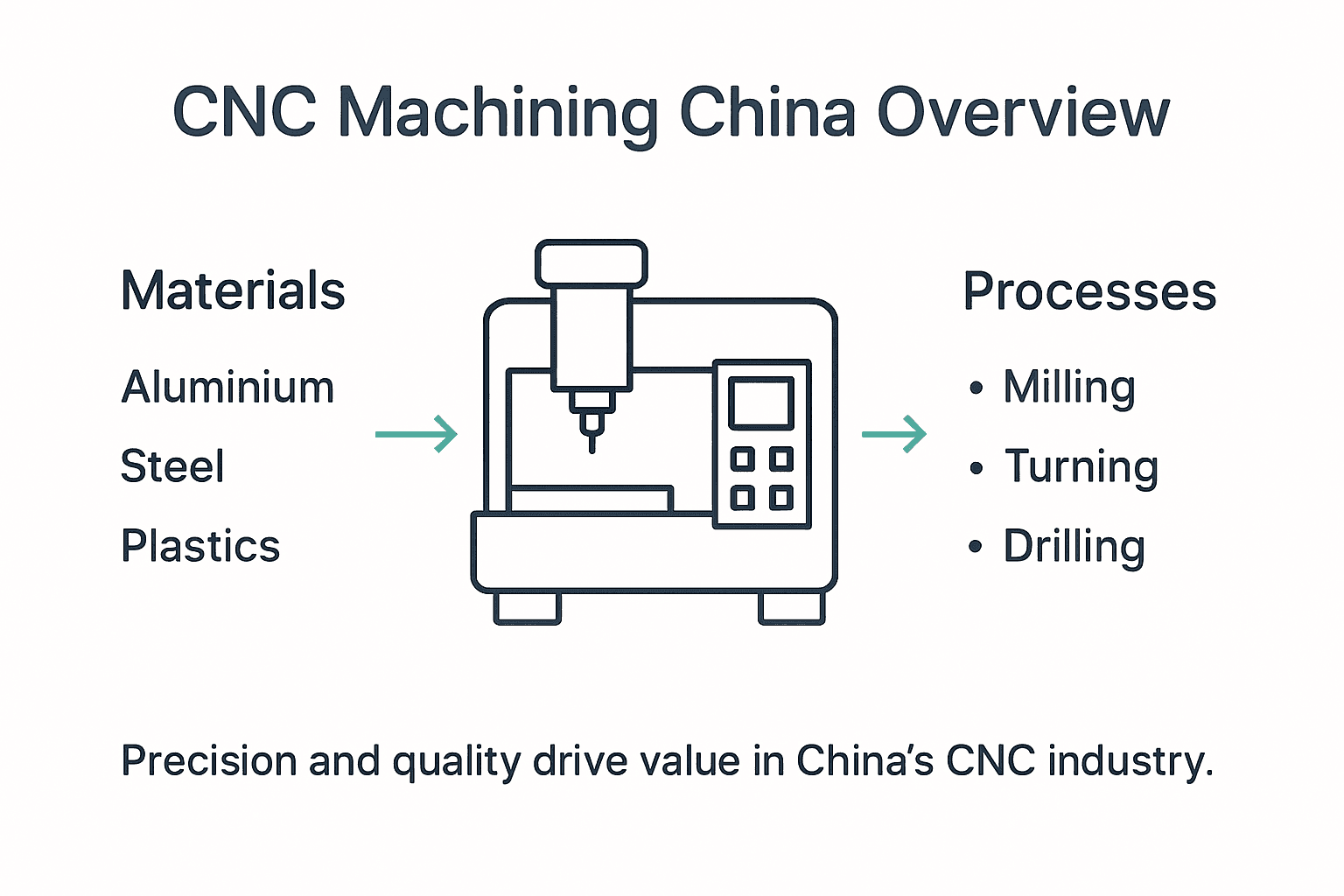

Computer Numerical Control (CNC) machining is a sophisticated precision manufacturing process that transforms raw materials into intricate components using computer-controlled tools. These advanced services leverage automated machinery to cut and shape materials with extreme accuracy across multiple industries and applications.

Typical CNC machining services encompass several core operations, including:

These services provide remarkable versatility, handling diverse materials like aluminium, steel, titanium, plastics, and advanced composites. Manufacturing engineers can produce everything from intricate aerospace components to complex medical device prototypes, all while maintaining consistently high precision and tight tolerances.

The following table summarises the primary business impacts of core CNC machining processes:

| CNC Process | Key Benefit | Typical Application |

|---|---|---|

| Milling | Complex shape creation | Aerospace structures |

| Turning | High repetition accuracy | Shaft and axle manufacturing |

| Drilling | Consistent hole precision | Mechanical assemblies |

| Grinding | Ultra-smooth finishes | Surgical and optical components |

Modern CNC machining integrates sophisticated Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software, enabling manufacturers to translate digital design specifications directly into physical components. This technological integration allows for rapid prototyping, iterative design improvements, and scalable production across small batch and mass manufacturing scenarios.

Pro Tip: When selecting a CNC machining service, always request material compatibility testing and dimensional accuracy reports to ensure your components meet exact engineering specifications.

Advanced CNC machining technologies are transforming precision manufacturing through sophisticated innovations that push the boundaries of what's possible in material processing. Recent technological developments have introduced high-precision multi-axis machining capabilities with adaptive path planning and intelligent control strategies, enabling unprecedented levels of manufacturing flexibility and performance.

Key technological variations in CNC machining services include:

Modern CNC service providers leverage cutting-edge technologies like digital twin simulations and cloud-based control systems to deliver increasingly sophisticated manufacturing solutions. High-speed motorised spindle technologies have become particularly critical, featuring precision bearing developments and thermal error compensation methods that dramatically improve machining reliability and performance.

The integration of artificial intelligence and machine learning is revolutionising CNC machining, allowing for predictive maintenance, autonomous error correction, and unprecedented levels of manufacturing intelligence. These technological advancements are driving a new era of precision manufacturing that can adapt dynamically to complex engineering challenges.

Pro Tip: When evaluating CNC machining services, prioritise providers who demonstrate transparent technological capabilities and can articulate their specific multi-axis and AI-integration strategies.

Material selection and surface finishing are pivotal aspects of CNC machining that dramatically influence a component's performance, durability, and aesthetic qualities. Surface finish treatments play a crucial role in enhancing material properties, improving corrosion resistance, and optimising overall part functionality.

Typical CNC machining materials encompass a wide range of options:

Surface finishing techniques offer multiple approaches to enhance material characteristics. Common treatments include:

Heat treatments such as annealing and tempering can fundamentally alter material properties, improving strength, ductility, and overall mechanical performance. These processes enable manufacturers to customise components for specific engineering requirements, ensuring optimal performance across diverse industrial applications.

Below is a comparison of popular CNC material types and their ideal usage contexts:

| Material Type | Notable Strength | Optimal Use Case |

|---|---|---|

| Aluminium | Lightweight durability | Automotive housings |

| Stainless Steel | Corrosion resistance | Medical instruments |

| Titanium | High strength-to-weight | Aerospace fasteners |

| Nylon | Chemical resistance | Industrial gears |

| Acetal | Low friction | Precision bearings |

Pro Tip: Always specify precise material and finish requirements during initial design consultations to ensure your CNC-machined components meet exact performance specifications.

Selecting a dependable CNC machining supplier in China requires a strategic approach that balances technical capabilities, quality assurance, and cost-effectiveness. Understanding the nuanced landscape of Chinese manufacturing can help procurement professionals make informed decisions about their precision engineering partnerships.

Critical evaluation criteria for Chinese CNC suppliers include:

Successful supplier selection involves comprehensive due diligence, including requesting detailed capability statements, reviewing past project portfolios, and conducting thorough technical discussions. Procurement managers should prioritise suppliers demonstrating consistent precision, technological innovation, and a proven track record of delivering complex engineering components across multiple industries.

Geographic advantages in regions like Guangdong and Shanghai provide additional benefits, with concentrated manufacturing ecosystems offering access to advanced technological infrastructure, specialised engineering talent, and sophisticated supply chain networks that support high-precision manufacturing requirements.

Pro Tip: Request comprehensive quality documentation and conduct virtual factory audits to validate a Chinese CNC supplier's actual manufacturing capabilities before finalising any partnership.

Procurement professionals must adopt a multifaceted approach when assessing CNC machining quotes from Chinese manufacturers. Understanding the nuanced relationship between lead times, pricing, and manufacturing quality is crucial for successful international sourcing.

Critical evaluation factors include:

Successful quote evaluation requires a holistic approach that goes beyond simple price comparisons. Procurement managers should request comprehensive documentation, including detailed manufacturing process descriptions, quality control methodologies, and explicit performance guarantees.

Modern Chinese CNC machining providers increasingly offer transparent pricing models and sophisticated communication channels, enabling international clients to conduct thorough assessments remotely. Advanced digital platforms now facilitate instant quotations, technical consultations, and real-time project tracking, significantly reducing traditional sourcing barriers.

Pro Tip: Request multiple quote iterations and conduct comprehensive technical discussions to ensure complete alignment between your engineering specifications and the manufacturer's capabilities.

Navigating the complexities of CNC machining in China involves overcoming challenges such as ensuring consistent quality, verifying advanced multi-axis capabilities, and managing lead times without compromising cost effectiveness. If your goal is to achieve exacting tolerances and superior surface finishes backed by stringent quality management, WJ Prototypes offers the comprehensive solution you need. Leveraging extensive expertise in aerospace, medical, and industrial sectors, WJ Prototypes combines traditional CNC machining with cutting-edge AI-integrated control systems to deliver parts that meet your precise specifications.

Experience transparent communication, ISO-certified quality assurance, and rapid prototyping workflows tailored to your project requirements. Discover how our advanced manufacturing technologies and breadth of material options can streamline your development cycle with fast, reliable, and affordable CNC machining services. Take the next step towards precision manufacturing by exploring the full suite of services at WJ Prototypes today. Request an instant quote or consult with our engineers to transform your design concepts into high-quality production reality with confidence and speed.

CNC machining, or Computer Numerical Control machining, is a precision manufacturing process that utilises computer-controlled tools to cut and shape raw materials into intricate components with high accuracy.

The core CNC machining processes include milling, turning, drilling, and grinding, each serving specific applications such as complex shape creation, cylindrical part manufacturing, and achieving ultra-smooth finishes.

Selecting a dependable CNC machining supplier involves evaluating their technical capabilities, quality management processes, and operational considerations. Key factors include ISO certification, advanced machinery, and clear communication.

CNC machining can effectively utilise a variety of materials, including metals like aluminium, stainless steel, and titanium, as well as plastics like nylon and acetal, allowing manufacturers to customise components based on specific engineering requirements.

Precision CNC Machining in China | Fast, Flexible & Reliable Manufacturing

Precision Machining in China | Why China Leads Global Production

ISO-Certified CNC Machining in China | Fast, Reliable Quotes

Custom CNC Machining in China | From Prototype to Production