- Room 1807, Unit 9, Building 2, Shangxing Commercial Street, Shangde Road, Shangxing Community, Xinqiao Subdistrict, Bao'an District, Shenzhen City, China

Aerospace & UAV

WJ Prototypes is your 3D manufacturing partner from prototype to large scale production.

Consumer Electronics

New Product Introduction Solutions for Consumer Electronics.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Automotive

New Product Introduction Solutions for Automotive

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

Cutting weeks from development cycles while hitting nanometre-level tolerances is not a distant goal for today's aerospace and automotive engineers. Precision engineering now blends CAD modelling with advanced fabrication techniques, producing prototypes that match digital designs from the start. This approach matters because reliability, speed, and functional accuracy define whether your next product iteration reaches the factory floor or stalls in costly revision loops. Discover how combining error compensation, real-time metrology, and strategic method selection empowers your team to create dependable, production-ready prototypes.

| Point | Details |

|---|---|

| Precision Engineering is Essential | Integrating CAD modelling with advanced fabrication techniques ensures high accuracy and repeatability in prototypes, crucial for sectors like aerospace and automotive. |

| Method Selection Matters | Each prototyping technology has distinct advantages and limitations; choosing the right method based on design requirements directly impacts prototype quality and development speed. |

| Material and Tolerances Require Attention | Proper material selection and understanding tolerance specifications are critical to ensure prototypes provide reliable performance validation without incurring unnecessary costs. |

| Hybrid Approaches Enhance Efficacy | Combining methods strategically, such as additive and subtractive processes, optimises both quality and cost, expediting prototype development and validation. |

Precision engineering forms the backbone of modern prototyping, transforming how engineers accelerate product development cycles. Rather than building prototypes through trial and error, today's manufacturers combine CAD modelling with advanced fabrication techniques to produce parts that meet exacting specifications from the first iteration. This integration shortens time-to-market whilst maintaining the accuracy required by aerospace and automotive industries.

Modern prototyping relies on achieving what researchers describe as repeatability and precision in design and manufacturing. This means every prototype produced must match its digital blueprint reliably. Engineers employ error compensation techniques alongside sophisticated control systems to reach nanometre-level tolerances. When you're testing aerodynamic components or validating engine concepts, these minute accuracy levels prevent costly redesigns later.

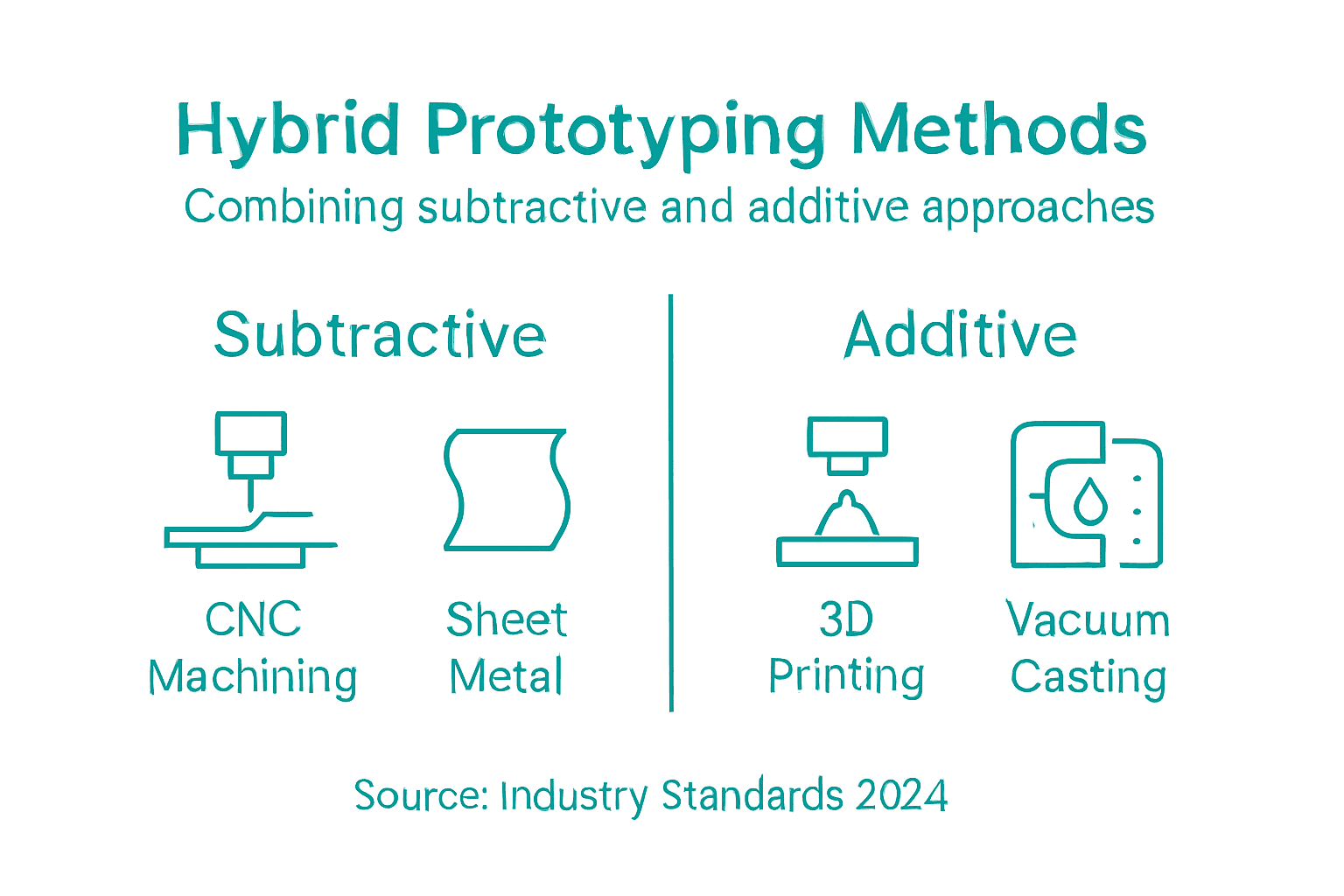

The convergence of traditional methods with additive manufacturing creates unprecedented flexibility. CNC machining handles dense metal components requiring high strength, whilst layer-by-layer fabrication approaches tackle complex geometries that would be impossible to machine conventionally. This combination lets manufacturers produce intricate prototypes with internal channels, undercuts, and features that validate real-world performance before full-scale production.

What makes this approach genuinely transformative is the feedback loop it creates. Your R&D team tests a prototype, identifies improvements, and launches the next iteration within weeks rather than months. Precision tolerances mean you're testing actual performance characteristics, not approximations. This accelerates validation cycles and reduces the gap between prototype and production-ready design.

Implementing precision engineering in your prototyping strategy requires selecting the right manufacturing partner. Look for facilities with certified calibration systems, experienced tooling engineers, and proven track records in your sector. The difference between a manufacturer holding ±0.1 millimetre tolerances and one achieving ±0.05 millimetres directly impacts whether your prototype reveals genuine performance or masks critical issues.

Pro tip: Request tolerance stacks and dimensional reports for your prototypes rather than accepting simple "within tolerance" confirmations; this data reveals whether your design margins are adequate for production scaling.

Selecting the right prototyping method depends entirely on your design requirements, material needs, and production timeline. Each technology brings distinct advantages and trade-offs. Understanding these differences helps you make informed decisions that directly impact both your prototype quality and development speed.

CNC Machining excels at producing high-strength metal components with exceptional dimensional accuracy. You get repeatable tolerances down to micrometres, making it ideal for testing structural performance in aerospace applications. The drawback? Complex internal geometries require multiple setups, and material removal creates waste. CNC works best for dense metal parts where precision matters more than design flexibility.

Additive Manufacturing reverses this equation entirely. Layer-by-layer construction means you can produce intricate internal channels, lattice structures, and organic shapes impossible to machine. Design flexibility is remarkable. However, material properties vary depending on the process you choose, and surface finishes typically require post-processing. Additive manufacturing integration with CAD design creates powerful synergies for complex automotive prototypes.

Sheet Metal Fabrication bridges the gap for applications requiring moderate complexity with tight tolerances. You can produce functional assemblies quickly, test how components interact, and validate fit within larger systems. It's particularly valuable for validating mechanical assemblies before investing in injection moulding tooling.

Injection Moulding and Die Casting shine for producing multiple prototype iterations with consistent material properties. Once tooling is complete, you generate parts rapidly and cost-effectively. The trade-off is upfront tooling investment and design constraints that come with mould requirements.

Vacuum Casting offers middle ground for small production runs. It captures surface detail beautifully and works with various resin formulations, though material strength doesn't match metal components. Comparative capabilities across precision prototyping methods reveal that technology choice directly influences both performance validation and timeline.

The smart approach combines methods. Use additive manufacturing to validate geometry and ergonomics, then switch to CNC machining for final metal prototypes that undergo real-world testing. This staged approach reduces risk and accelerates your time to market.

To better understand each prototyping technology’s strategic role, see this side-by-side comparison:

| Technology | Ideal Use Case | Limitations | Validation Focus |

|---|---|---|---|

| CNC Machining | High-strength, precise metal parts | Limited internal geometry, material waste | Dimensional and structural tests |

| Additive Manufacturing | Complex geometries, rapid iterations | Variability in material properties, surface finishing | Fit and ergonomic validation |

| Sheet Metal Fabrication | Moderate complexity, assemblies | Low suitability for intricate features | Functional fit and interactions |

| Injection Moulding/Die Casting | Rapid, scalable iterations | Upfront tooling cost, design constraints | Consistency, production readiness |

| Vacuum Casting | Small runs, fine details | Lower mechanical strength than metals | Surface quality, design replicas |

Pro tip: Specify your tolerance requirements in your manufacturing brief; this single step ensures your chosen technology can deliver the precision your design actually needs rather than paying for unnecessary accuracy.

Material selection and tolerance management form the critical foundation of successful prototype development. Get these wrong, and your prototype becomes misleading rather than informative. Get them right, and you validate your design with confidence before investing in production tooling.

Choosing the correct material requires matching prototype material properties to what your final production part will use. If you're designing an aerospace component from aluminium alloy, testing with plastic resin won't reveal whether your thermal management strategy actually works. Similarly, if your automotive design relies on steel's fatigue resistance, a prototype cast in alternative materials masks critical performance factors. The material choice directly determines whether your prototype reveals genuine performance or merely validates geometry.

Tolerance specification demands equal attention. Many engineers specify overly tight tolerances without understanding the cost implications or manufacturing reality. A ±0.05 millimetre tolerance costs substantially more than ±0.1 millimetre, yet your design might function perfectly with the looser tolerance. Achieving reproducible high-accuracy results requires matching tolerance requirements to actual functional needs rather than specifying blanket accuracy across all dimensions.

Here's the practical approach: identify which dimensions actually affect performance or fit. Your bearing bore might need ±0.02 millimetres for proper operation. Your aesthetic surface features might accept ±0.5 millimetres without affecting function. By distinguishing between critical and non-critical dimensions, you reduce manufacturing costs whilst maintaining performance validation.

Real-time metrology during manufacturing ensures tolerances remain within specification. Modern precision facilities employ coordinate measuring machines and optical inspection systems that catch deviations before parts leave the shop. This verification transforms tolerance specifications from theoretical ideals into validated certainties. Advanced manufacturing techniques including tolerance optimisation integrate this feedback directly into production adjustments.

When sourcing materials from precision manufacturers, request material certs and test reports. These documents verify that your aluminium truly meets 6061-T6 specifications, your stainless steel possesses the stated hardness, and your composite materials have verified fibre orientation. Without this verification, you're accepting assumptions rather than facts.

Pro tip: Create a tolerance matrix in your design documentation, clearly marking which dimensions drive function versus aesthetics; this single document saves manufacturing time and prevents costly back-and-forth negotiations on specification requirements.

Different industries impose vastly different demands on prototyping. What works brilliantly for consumer electronics might fail catastrophically for aerospace. Understanding your sector's unique requirements determines whether your prototype becomes a validation tool or a costly dead end.

Aerospace demands absolute uncompromising precision. Your prototype must withstand extreme temperatures, pressures, and vibration cycles. Materials cannot simply perform adequately; they must demonstrate reliability margins that exceed real-world conditions by substantial factors. A 0.1 millimetre dimensional variance might be acceptable in consumer goods but could trigger structural failure in an aircraft engine component. Testing occurs under conditions that simulate years of operational stress within weeks.

Automotive prototyping requires rapid iteration combined with material authenticity. Engineers need to validate crashworthiness, thermal management, and structural durability. Lightweight high-performance components dominate modern automotive design, meaning your prototype must demonstrate that weight reduction doesn't compromise safety. Multiple iterations occur quickly as teams optimise for strength-to-weight ratios and manufacturing feasibility.

Medical devices impose regulatory scrutiny from day one. Biocompatibility testing, sterility validation, and functional performance under physiological conditions cannot be approximate. Your prototype must meet or exceed specifications that protect human life. Material selection considers not just mechanical properties but also tissue response and long-term implant stability.

Semiconductor and optics sectors demand surface finishes measured in nanometres. Standard tolerance specifications become insufficient when optical performance depends on surface roughness at atomic scales. Precision engineering across aerospace, biomedical, and semiconductor industries reveals how specialised methods address industry-specific requirements that general manufacturing cannot match.

Oil and gas applications require prototypes that survive corrosive environments, extreme pressures, and continuous operation under hostile conditions. Material selection becomes critical because standard engineering alloys corrode rapidly in subsurface conditions.

Identifying your sector's specific demands early prevents wasted prototype iterations. Request sector-specific case studies from your manufacturing partner. Their experience with comparable applications directly informs whether your prototype will genuinely validate your design or merely confirm what you already assumed.

This summary highlights how sector demands shape the prototyping approach:

| Sector | Main Priority | Essential Requirement | Typical Challenge |

|---|---|---|---|

| Aerospace | Maximum precision | Extreme environment validation | Microscopic tolerance margins |

| Automotive | Speed and authenticity | Material and crash testing | Balancing weight with safety |

| Medical Devices | Regulatory compliance | Biocompatibility, sterility | Proving performance in conditions |

| Semiconductors/Optics | Surface perfection | Atomic-scale surface metrology | Sub-nanometre finish requirements |

| Oil and Gas | Corrosion and pressure resistance | Material certification | Surviving harsh environments |

Pro tip: Document your sector's regulatory requirements and performance standards in your design brief; this single step ensures your prototype addresses actual compliance demands rather than generic specifications.

Prototyping budgets spiral when engineers don't understand what actually drives costs. Many projects exceed budgets not because manufacturing is inherently expensive, but because avoidable mistakes compound throughout development. Recognising these pitfalls early prevents wasteful spending and accelerates your path to validation.

Tolerance overspecification ranks as the single largest cost driver. Engineers frequently specify ±0.05 millimetre tolerances across every dimension when only three dimensions actually require that accuracy. The remaining dimensions could accept ±0.2 millimetres without affecting performance, yet manufacturing must maintain precision on all features. This unnecessary accuracy multiplies tooling complexity and production time. Requesting ±0.1 millimetre across the board costs significantly less than specifying tighter tolerances selectively.

Poor CAD model fidelity creates cascading rework. When your digital model lacks manufacturing detail, the manufacturer must interpret your intent, often incorrectly. This leads to prototype features that don't match your expectations, requiring costly revisions. Inaccurate tolerance setting and inadequate CAD modelling directly cause cost escalation and delays that ripple through your development schedule.

Method mismatch happens when you select an inappropriate manufacturing process for your geometry. Attempting to CNC machine a part better suited to injection moulding wastes time and material. Conversely, using additive manufacturing for a simple cylindrical component pays premium prices for unnecessary complexity. Matching the process to your actual requirements prevents this expensive error.

Failure to account for error compensation in design creates expensive surprises during manufacturing. Dynamic system behaviours, thermal effects, and material shrinkage must be anticipated. Material costs and process optimisation require rigorous upfront analysis to avoid costly reworks that derail schedules and budgets.

Material selection without cost analysis represents another common trap. Premium materials cost substantially more without always delivering superior prototyping results. Sometimes standard aluminium achieves your functional requirements at a fraction of the cost of speciality alloys.

The smartest approach involves collaborative design review before manufacturing begins. Experienced engineers spot these pitfalls immediately and suggest cost-effective alternatives without compromising validation.

Pro tip: Request a design review and cost optimisation consultation before committing to manufacturing; manufacturers who invest this time upfront save you thousands by identifying unnecessary complexity and tolerance overspecification.

Modern prototyping transcends choosing a single manufacturing method. The most effective approach combines multiple technologies strategically, leveraging each method's strengths whilst compensating for its limitations. This integrated strategy accelerates validation whilst optimising both cost and quality.

Hybrid manufacturing represents the frontier of precision prototyping. Combining additive and subtractive processes allows you to build complex geometry rapidly, then machine critical surfaces to exact specifications. You might 3D print a component's intricate internal structure, then CNC machine the bearing surfaces that demand nanometre-level accuracy. This hybrid approach delivers design freedom with precision performance that neither method achieves alone.

Digital prototyping complements physical fabrication. Before committing material and time to manufacturing, simulation and optimisation technologies including digital twins reveal performance characteristics with remarkable accuracy. Computational fluid dynamics predicts aerodynamic behaviour. Finite element analysis validates structural integrity under load. Thermal simulation identifies hotspots before your first physical prototype arrives.

This digital first approach means your physical prototype represents your third or fourth design iteration, not your first. Your first two iterations happened virtually, eliminating obvious failures before manufacturing begins. This strategy compresses development cycles and reduces rework.

Staged prototyping sequences technologies intelligently. Early prototypes validate geometry and fit using rapid additive manufacturing. Mid-stage prototypes test functional performance using materials matching production specifications. Final prototypes undergo stress testing using production-equivalent manufacturing methods. Each stage answers specific questions, building confidence progressively towards production readiness.

Strategic process selection requires understanding your validation priorities. Hybrid methods combining subtractive and additive processes enhance precision whilst managing cost and time constraints. The key is matching each process to its specific purpose within your overall development strategy.

Integrating CAD, simulation, and process control creates a cohesive system where digital and physical prototyping inform each other continuously. Your manufacturing partner should facilitate this integration, not simply execute isolated manufacturing tasks.

Pro tip: Plan your prototyping strategy across three stages before manufacturing begins, specifying which validation questions each stage answers and which technology best serves that purpose.

Achieving flawless precision and optimum material selection is the cornerstone of breakthrough prototyping as explored in the article. If you are struggling with tolerance overspecification, method mismatches, or sector-specific demands slowing your product development cycle, you are not alone. The need for exacting repeatability, high-strength materials, and strategic integration of additive and subtractive techniques can present complex challenges that demand an experienced partner.

At WJ Prototypes, we specialise in delivering high-quality, rapid prototyping services tailored for industries requiring stringent precision engineering such as aerospace, automotive, and medical devices. Our comprehensive manufacturing capabilities include SLA, SLS, MJF, DMLS, CNC machining, vacuum casting, injection moulding and more to fit every critical tolerance and material specification. By blending advanced fabrication technologies with rigorous tolerance management and material certification, we help you accelerate validation and reduce costly rework.

Discover how our ISO certified expertise and global delivery can transform your prototyping strategy today. Contact WJ Prototypes for instant quotes and detailed service insights. Take control of your development timeline and validate designs with confidence by partnering with us now.

Precision engineering in prototyping involves using advanced techniques and technologies to create highly accurate prototypes that meet specific tolerances from the first iteration. This approach reduces development times and increases the reliability of prototypes in industries such as aerospace and automotive.

Additive manufacturing builds prototypes layer by layer, allowing for complex geometries and intricate designs that traditional methods, like CNC machining, may struggle to create. This provides greater design flexibility but may require post-processing for surface finishes.

Material selection is vital because the properties of the prototype material must align with those of the final production part. Using the wrong material can lead to inaccurate testing results and potentially mask critical performance issues.

Common pitfalls include overspecifying tolerances, poor CAD model fidelity, mismatching manufacturing methods to design requirements, and failing to account for error compensation. These issues can lead to increased costs and delayed project timelines.

What Is The Role of Engineers in Prototyping – Driving Innovation

Precision Engineering in Prototyping | Sourcing from China

Benefits of Rapid Prototyping for Precision Manufacturing in China

Role of Prototyping in Product Development: Complete Guide

Dust Free Film for Spray Booth Protection