- Room 1807, Unit 9, Building 2, Shangxing Commercial Street, Shangde Road, Shangxing Community, Xinqiao Subdistrict, Bao'an District, Shenzhen City, China

Aerospace & UAV

WJ Prototypes is your 3D manufacturing partner from prototype to large scale production.

Consumer Electronics

New Product Introduction Solutions for Consumer Electronics.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Automotive

New Product Introduction Solutions for Automotive

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

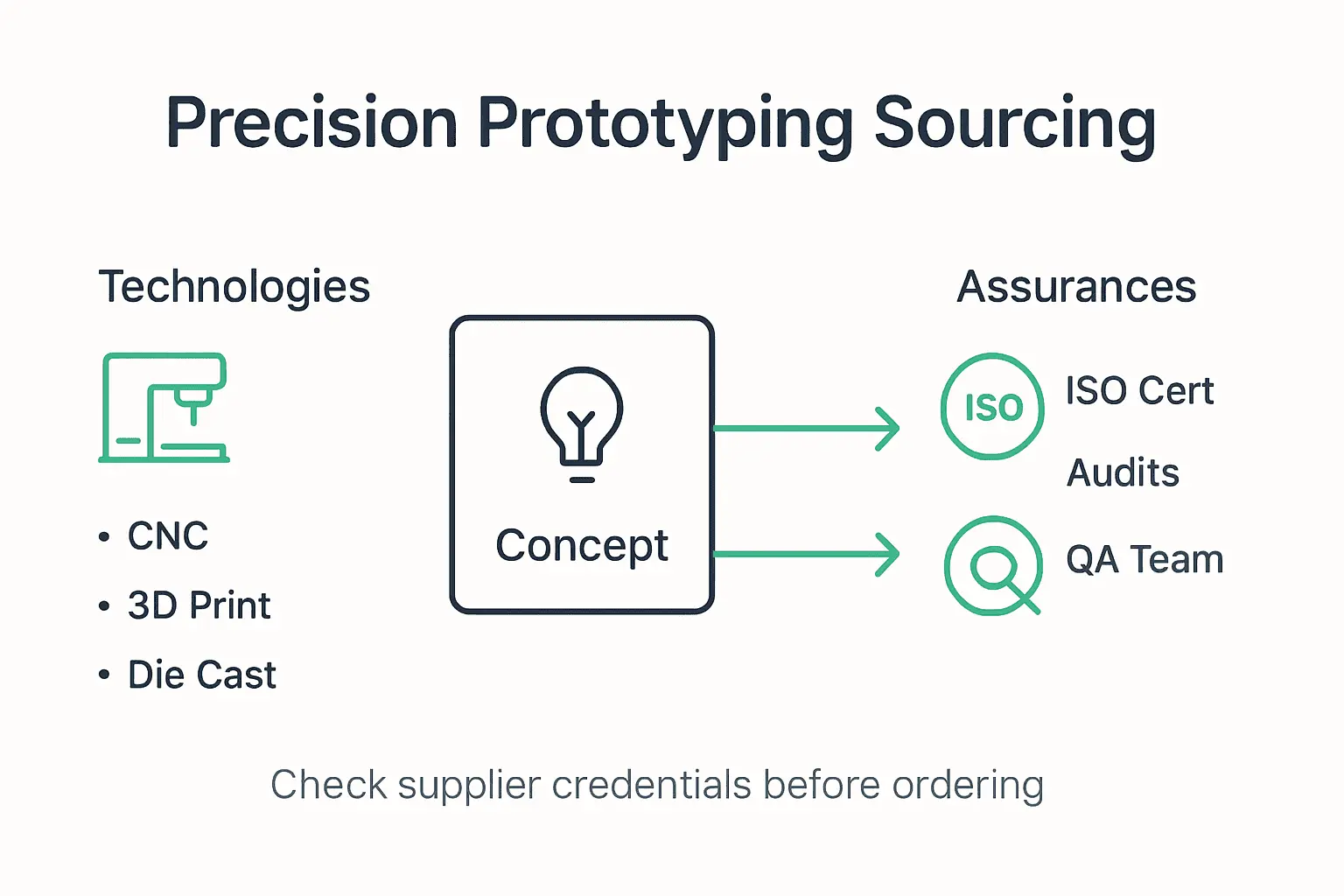

Global demand for high-precision prototyping is driving aerospace and automotive leaders—including many British engineers—to seek smarter sourcing solutions in China. With over 70% of major British aerospace firms now relying on Chinese prototyping partners, the pressure to secure reliable and verified manufacturing has never been higher. This guide provides key strategies for navigating advanced prototyping technologies, rigorous supplier certification, and proven quality assurance practices essential for success in complex engineering markets.

| Point | Details |

|---|---|

| Precision Engineering Focus | Emphasises exceptional dimensional accuracy and consistency in prototype development to enhance product performance. |

| Advanced Manufacturing Technologies | Utilises methods like CNC machining and additive manufacturing for producing high-precision prototypes in various industries. |

| Supplier Quality Assurance | Requires robust certifications and multi-stage verification processes to ensure consistent quality in prototype sourcing from China. |

| Navigating Risks in Sourcing | Involves developing comprehensive technical specifications and maintaining clear communication to mitigate financial and compliance risks. |

Precision engineering represents a sophisticated approach to prototyping that transforms conceptual designs into highly accurate, repeatable physical models. At its core, precision engineering focuses on creating prototypes with exceptional dimensional accuracy, minimal tolerances, and remarkable consistency across manufacturing processes. Prototype strategies in engineering design fundamentally depend on understanding how minute variations can profoundly impact product performance.

In technical terms, precision engineering encompasses several critical characteristics that distinguish it from standard prototyping approaches. These include tolerance control, dimensional accuracy, resolution, and repeatability. Engineers meticulously measure and manage these parameters to ensure that each prototype precisely matches design specifications. Key concepts in precision engineering demonstrate that even microscopic deviations can significantly influence a prototype's functional capabilities, making exacting standards paramount in advanced manufacturing.

The practical application of precision engineering spans multiple manufacturing techniques, including CNC machining, additive manufacturing, and advanced casting processes. Each method requires unique strategies to achieve optimal dimensional control. Precision prototyping demands sophisticated measurement tools, advanced computational modeling, and rigorous quality control protocols to validate every geometric detail. By integrating computational design, high-resolution manufacturing technologies, and meticulous measurement techniques, engineers can create prototypes that serve as near-perfect representations of final product specifications.

Pro tip: Invest in high-precision measurement equipment like coordinate measuring machines (CMMs) and laser scanning technologies to validate your prototype's dimensional accuracy throughout the development process.

China's manufacturing landscape has evolved to become a global powerhouse in prototyping technologies, offering an extensive range of advanced manufacturing capabilities. Cutting-edge prototyping techniques across Chinese manufacturing sectors demonstrate a comprehensive approach to precision engineering, encompassing multiple sophisticated methods for producing complex prototype designs across various industries.

The primary prototyping technologies employed in China include several advanced manufacturing techniques. CNC machining stands at the forefront, offering multi-axis precision for intricate metal and plastic components. Additive manufacturing technologies like Stereolithography (SLA), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), and Fused Deposition Modeling (FDM) provide flexible solutions for creating complex geometries with remarkable accuracy. Rapid prototyping techniques utilised by Chinese manufacturers also incorporate advanced methods such as injection molding, vacuum casting, and sheet metal fabrication, enabling versatile production capabilities.

These technologies are particularly critical in high-precision industries like aerospace, automotive, medical devices, and electronics. Each manufacturing technique offers unique advantages: CNC machining provides exceptional dimensional accuracy, 3D printing enables complex geometrical designs, injection molding supports high-volume production, and vacuum casting allows for rapid silicone mould creation. Chinese manufacturers have strategically developed these technologies to offer engineers and product developers a comprehensive suite of prototyping solutions that balance speed, precision, and cost-effectiveness.

Here's a concise comparison of major prototyping technologies utilised in China and their core advantages:

| Technology | Typical Materials | Key Advantage | Notable Industry Uses |

|---|---|---|---|

| CNC Machining | Metals, Plastics | High dimensional accuracy | Aerospace, Automotive |

| Stereolithography (SLA) | Photopolymer resin | Fine surface quality | Medical Devices, Electronics |

| Selective Laser Sintering (SLS) | Nylon, Thermoplastics | Strong complex parts | Automotive, Electronics |

| Vacuum Casting | Silicone, Plastics | Fast multi-part creation | Consumer Products |

| Injection Moulding | Thermoplastics | High-volume efficiency | Automotive, Electronics |

This summary provides a quick reference for selecting the best-fit prototyping method based on project needs.

Pro tip: When sourcing prototypes from China, request detailed material and process specifications to ensure the selected manufacturing technology precisely matches your project's technical requirements.

Ensuring consistent quality when sourcing prototypes from China requires a comprehensive approach to supplier verification and quality management. Rigorous quality assurance protocols in Chinese manufacturing emphasise systematic verification processes that go far beyond surface-level assessments. International buyers must navigate a complex landscape of certifications, factory audits, and compliance standards to mitigate potential risks and guarantee exceptional prototype production.

The cornerstone of quality assurance in Chinese prototyping involves multiple certification standards that demonstrate a manufacturer's commitment to excellence. ISO 9001 remains the primary quality management system certification, providing a robust framework for consistent product quality. Additionally, industry-specific certifications play a crucial role: IATF 16949 for automotive applications, AS9100 for aerospace engineering, and ISO 14001 for environmental management systems. Comprehensive factory and supplier audit methodologies reveal that these certifications are not merely paperwork but represent rigorous operational standards that manufacturers must consistently maintain.

Successful quality assurance extends beyond certification documentation. Sophisticated buyers implement multi-stage verification processes including detailed product specifications, pre-production sample reviews, periodic factory inspections, and ongoing performance monitoring. These strategies ensure that Chinese prototyping suppliers not only possess the necessary certifications but also demonstrate consistent technical capabilities, advanced manufacturing technologies, and unwavering commitment to meeting international quality standards. Critical evaluation criteria include technological infrastructure, quality control processes, workforce expertise, and the ability to deliver precise, repeatable prototype production across diverse industrial requirements.

The table below outlines essential supplier certifications and their global significance in prototyping quality assurance:

| Certification | Focus Area | Global Recognition | Typical Application Scope |

|---|---|---|---|

| ISO 9001 | Quality Management | Widely recognised | General manufacturing |

| IATF 16949 | Automotive Quality | Automotive sectors | Vehicle components, safety |

| AS9100 | Aerospace Quality | Aerospace industry | Aircraft, aerospace parts |

| ISO 14001 | Environmental Compliance | International standards | Sustainable production |

This reference can assist buyers in assessing supplier compliance for high-precision prototyping.

Pro tip: Request comprehensive quality documentation and recent third-party audit reports when evaluating potential Chinese prototyping suppliers to gain deeper insights into their actual manufacturing capabilities.

Sourcing prototypes from China requires a strategic approach to mitigate complex financial, legal, and operational risks. Comprehensive risk management strategies for international procurement highlight the critical importance of structured due diligence processes that extend far beyond traditional cost considerations. Engineers and procurement professionals must develop nuanced strategies to navigate the intricate landscape of international manufacturing relationships.

The primary challenges in Chinese prototyping sourcing encompass several interconnected risk domains. Intellectual property protection stands as a paramount concern, requiring robust contractual frameworks and meticulous supplier vetting. Minimum order quantity (MOQ) negotiations, payment security mechanisms, and detailed product specifications become essential safeguards against potential misunderstandings. Identifying and mitigating supplier-related risks demands sophisticated screening techniques, including comprehensive background checks, verification of claimed certifications, and detailed assessment of actual manufacturing capabilities.

Successful risk management in Chinese prototyping sourcing involves a multi-layered approach that balances cost efficiency with comprehensive risk mitigation. Critical strategies include developing detailed technical specifications, implementing rigorous quality control protocols, establishing clear contractual terms, and maintaining ongoing communication channels. Sophisticated buyers leverage third-party inspection services, maintain multiple supplier relationships, and invest in building long-term partnerships that prioritise transparency, technical competence, and mutual understanding. Advanced risk management techniques also involve continuous monitoring of geopolitical developments, trade regulations, and industry-specific compliance requirements that could impact prototype production and delivery.

Pro tip: Develop a comprehensive supplier risk assessment matrix that evaluates technical capabilities, financial stability, compliance history, and communication effectiveness before initiating any prototyping project.

Sourcing prototypes from China presents a complex landscape of potential challenges that demand strategic navigation and proactive risk management. Comprehensive strategies for mitigating sourcing complications reveal that successful international procurement requires far more than simply identifying the lowest cost provider. Engineers and procurement professionals must develop a nuanced understanding of the potential obstacles that could derail their prototyping projects.

The most critical pitfalls in Chinese prototyping sourcing stem from communication barriers, quality inconsistencies, and inadequate supplier verification. Language differences and cultural misunderstandings can lead to significant misinterpretations of technical specifications and project requirements. Unreliable suppliers might present impressive initial portfolios but fail to deliver consistent quality across production runs. Advanced supplier verification techniques become essential, including comprehensive background checks, on-site factory audits, and thorough review of manufacturing processes. Technical buyers must implement rigorous screening mechanisms that go beyond surface-level documentation and assess actual manufacturing capabilities.

Mitigating these risks requires a multi-dimensional approach that combines technological expertise, cultural intelligence, and systematic verification processes. Successful prototyping sourcing strategies involve developing detailed, bilingual technical specifications, establishing clear communication protocols, implementing ongoing quality monitoring, and maintaining flexible contractual frameworks. Advanced buyers leverage professional sourcing agents, third-party inspection services, and develop long-term relationships with suppliers who demonstrate consistent technical competence, transparency, and commitment to meeting international quality standards. Understanding the nuanced challenges of cross-border manufacturing enables engineers to transform potential pitfalls into opportunities for strategic collaboration.

Pro tip: Develop a comprehensive supplier evaluation scorecard that objectively assesses technical capabilities, communication effectiveness, quality consistency, and cultural compatibility before initiating any prototyping project.

Precision prototyping for aerospace and automotive industries demands an extraordinary level of technical sophistication and rigorous quality management. Advanced prototyping processes in aerospace engineering require manufacturers to implement comprehensive quality control strategies that exceed standard industrial requirements. These high-stakes sectors demand prototypes that demonstrate exceptional dimensional accuracy, material integrity, and performance reliability under extreme operational conditions.

In aerospace and automotive applications, material selection and manufacturing precision become critical differentiators. Prototype development must account for complex performance requirements including structural integrity, weight optimisation, thermal resistance, and mechanical stress tolerance. Advanced manufacturing techniques like computer numerical control (CNC) machining, additive manufacturing, and precision casting enable engineers to create intricate components with microscopic tolerances. Innovative 3D printing technologies for aerospace components have revolutionised prototype development, allowing for complex geometries and lightweight structural designs that were previously impossible to manufacture.

Successful prototyping in these sectors requires a holistic approach that integrates computational modelling, advanced material science, and stringent quality verification processes. Engineers must develop comprehensive test protocols that simulate real-world operational environments, including extreme temperature variations, mechanical stress, and prolonged performance scenarios. Collaborative design methodologies, involving continuous communication between design teams, materials experts, and manufacturing specialists, ensure that prototypes meet the exacting standards required for aerospace and automotive applications. This interdisciplinary approach enables rapid iteration, risk mitigation, and innovative solution development.

Pro tip: Implement multi-stage validation protocols that include computational simulation, material testing, and progressive physical stress testing to ensure prototype performance meets critical aerospace and automotive industry standards.

Navigating the complex world of precision engineering and sourcing high-quality prototypes from China can challenge even the most experienced product developers. Common obstacles like maintaining strict dimensional accuracy, understanding advanced manufacturing methods such as CNC machining and additive manufacturing, and ensuring supplier certifications while avoiding costly delays highlight the importance of partnering with a reliable prototyping specialist.

At WJ Prototypes, we address these pain points directly by offering a comprehensive suite of services tailored to meet the exacting standards highlighted in "Precision Engineering in Prototyping: Sourcing from China." Our ISO certified manufacturing facility utilises cutting-edge technologies including SLA, SLS, MJF, and CNC machining to create prototypes with exceptional tolerance control and repeatability. We specialise in industries that demand absolute precision including aerospace and automotive, ensuring every project receives rigorous quality assurance protocols and advanced material options.

Discover how WJ Prototypes can streamline your prototyping journey and help you overcome sourcing challenges through transparent communication, robust quality management, and fast turnaround times. Start your next project with confidence by exploring our full range of services at WJ Prototypes and learn about our manufacturing capabilities designed to bring your complex designs to life with unparalleled accuracy. Act now to experience truly dependable prototyping solutions that keep your product development on track and ahead of the competition.

Precision engineering in prototyping is characterized by exceptional dimensional accuracy, minimal tolerances, resolution, and repeatability. Engineers focus on meticulous measurements and management of these parameters to ensure prototypes closely match design specifications.

Key prototyping technologies include CNC machining for high precision, additive manufacturing techniques like Stereolithography (SLA) and Selective Laser Sintering (SLS), and traditional methods such as injection moulding and vacuum casting, each with distinct advantages tailored to various materials and project needs.

Maintaining quality assurance involves verifying supplier certifications like ISO 9001, conducting thorough factory audits, and implementing multi-stage verification processes that include pre-production sample reviews and ongoing performance monitoring to ensure consistency and adherence to international standards.

Common pitfalls include communication barriers and quality inconsistencies. These can be avoided by developing detailed bilingual specifications, establishing clear communication protocols, implementing ongoing quality monitoring, and performing rigorous supplier verification processes.

Cost-Effective Prototyping in China: A Guide for UK Manufacturers

Fast Prototyping Turnaround in China | Speed Up Product Development

How UK Manufacturers Can Reduce Lead Times with Chinese Rapid Prototyping