- Room 1807, Unit 9, Building 2, Shangxing Commercial Street, Shangde Road, Shangxing Community, Xinqiao Subdistrict, Bao'an District, Shenzhen City, China

Aerospace & UAV

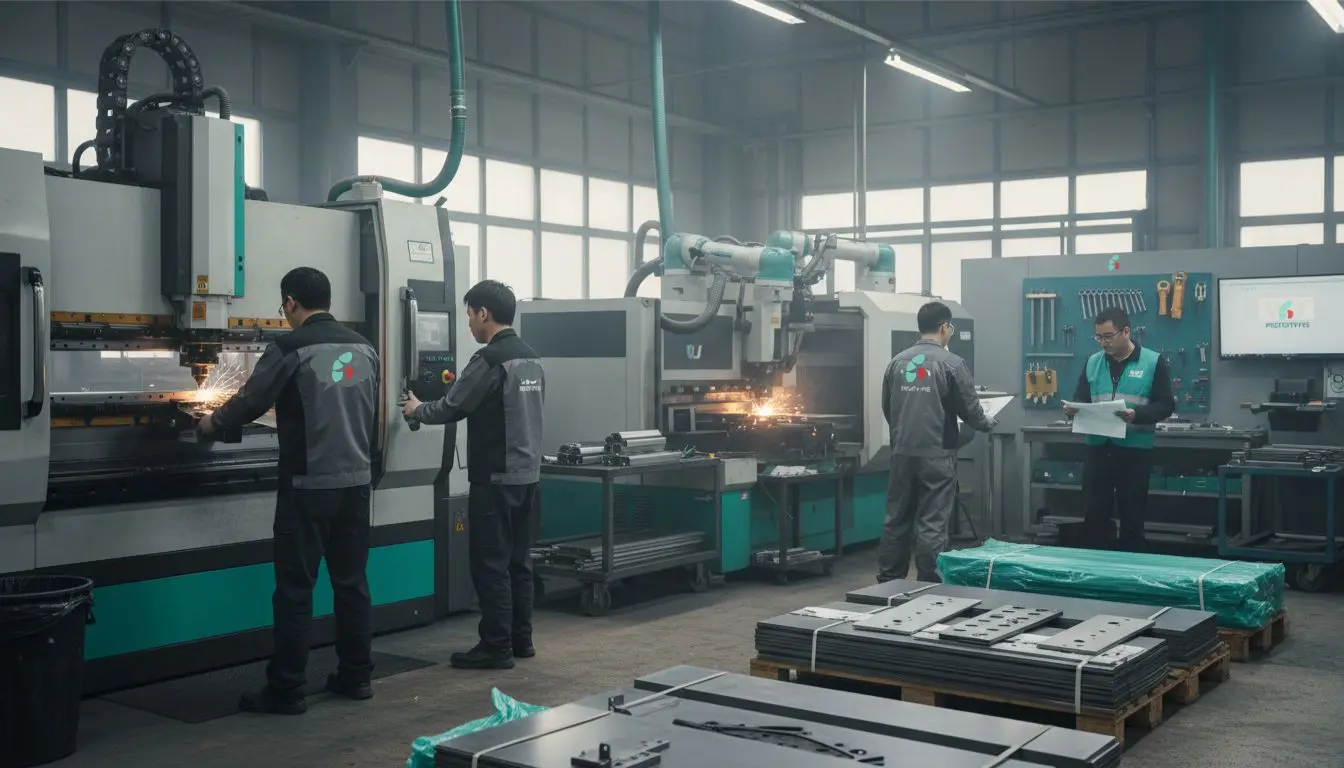

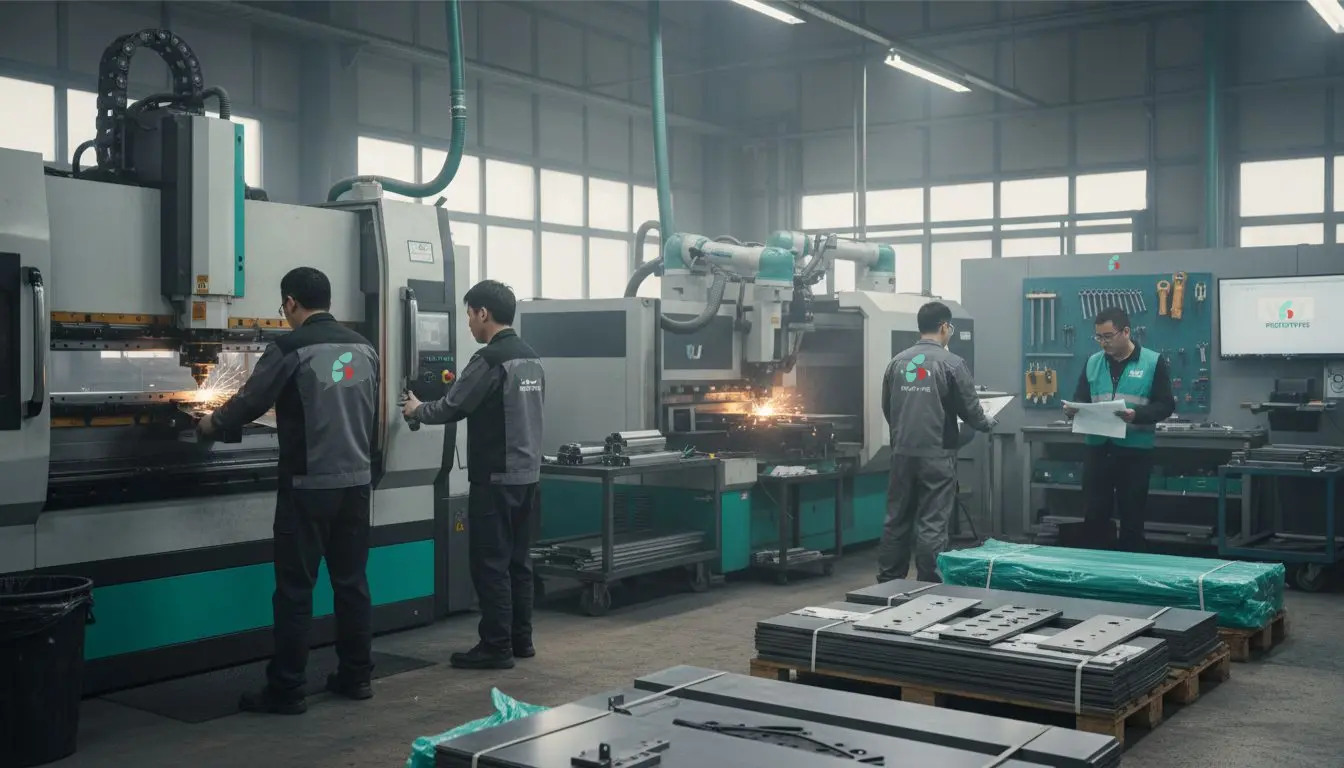

WJ Prototypes is your 3D manufacturing partner from prototype to large scale production.

Consumer Electronics

New Product Introduction Solutions for Consumer Electronics.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Automotive

New Product Introduction Solutions for Automotive

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

Sheet metal fabrication lies at the heart of british industry, powering sectors from aerospace to precision medical devices. This intricate field transforms simple sheet metal into vital components using techniques that blend innovation with tradition. In fact, more than 70% of modern manufacturing involves sheet metal processes in some way. Exploring these methods gives valuable insight into materials, applications, and the evolving role of advanced technologies within every corner of manufacturing.

| Point | Details |

|---|---|

| Sheet Metal Fabrication Techniques | The process involves techniques like cutting, forming, joining, and finishing to transform flat metal sheets into complex components. |

| Material Versatility | Common materials such as carbon steel, aluminium, and stainless steel are used, each catering to different industrial applications with unique properties. |

| Prototyping Advantages | Techniques like two-point incremental forming enhance prototyping efficiency by allowing rapid design changes and reducing tooling costs. |

| Industry Applications | Sheet metal fabrication is crucial in sectors like aerospace, automotive, and medical devices, highlighting its broad applicability and importance. |

Sheet metal fabrication represents a complex and sophisticated manufacturing process involving transforming flat metal sheets into precise, functional components through strategic manipulation. This intricate craft encompasses multiple techniques designed to shape, cut, and form metal materials into diverse geometric configurations for industrial applications.

At its core, sheet metal fabrication includes several fundamental processes. Wikipedia describes deep drawing as a critical technique where a sheet metal blank is radially drawn into a forming die through mechanical punch action. This process becomes particularly sophisticated when the depth of the drawn part exceeds its diameter, achieved through a meticulously planned series of dies.

Another innovative technique is rubber pad forming, which offers unique manufacturing capabilities. According to Wikipedia, this metalworking process involves pressing sheet metal between a die and a rubber block, typically constructed from polyurethane. Under carefully controlled pressure, the rubber and sheet metal conform to the die's specific shape, enabling production of intricate parts. This method proves especially valuable for small to medium-sized production runs, providing significant advantages like integrated functionality and weight reduction.

Sheet metal fabrication processes can be broadly categorised into several key techniques:

![]()

The Role of Sheet Metal Fabrication guide provides additional insights into these transformative manufacturing strategies, highlighting the remarkable versatility of modern metalworking techniques.

Sheet metal fabrication relies on a diverse range of metallic materials, each offering unique properties and performance characteristics tailored to specific industrial requirements. Understanding these materials is crucial for engineers and designers seeking optimal solutions for complex manufacturing challenges.

Elo1 highlights carbon steel as a fundamental material in sheet metal fabrication, containing 0.05%–2.0% carbon and widely used for industrial and structural components. Its exceptional characteristics include robust strength, excellent weldability, and remarkable cost efficiency. Common carbon steel grades like A36, 1018, and 1045 demonstrate yield strengths ranging from approximately 250–400 megapascals, making them versatile for numerous engineering applications. Steel Stack USA emphasises aluminium as another critical sheet metal material. Prized for its non-magnetic properties, lightweight composition, and superior corrosion resistance, aluminium has become a preferred choice in aerospace and automotive industries. Its exceptional workability enables precise fabrication techniques like laser cutting, which offers unparalleled precision and manufacturing efficiency.

Key sheet metal materials include:

For comprehensive insights into material selection, our Sheet Metal Fabrication Materials resource provides detailed guidance on matching material properties with specific project requirements.

Sheet metal fabrication has revolutionised modern manufacturing by offering unprecedented flexibility, precision, and efficiency across multiple industrial sectors. The ability to transform raw metal sheets into complex, functional components represents a cornerstone of contemporary engineering and design strategies.

ArXiv highlights two-point incremental forming (TPIF) as a groundbreaking technique that dramatically enhances prototyping capabilities. This innovative process allows manufacturers to produce intricate shapes without relying on dedicated dies, significantly improving dimensional accuracy, material thickness distribution, and overall formability. Such advantages make TPIF particularly valuable for prototyping and low-volume production environments where design flexibility is paramount. ArXiv further emphasises the transformative potential of automation in sheet metal production. By integrating advanced mechatronic systems into hot-rolling processes, manufacturers can achieve unprecedented levels of efficiency, consistency, and quality. This approach substantially reduces manual interventions, leading to enhanced productivity and superior product standards across manufacturing workflows.

Key advantages of sheet metal fabrication in prototyping and production include:

For deeper insights into prototyping strategies, our Role of Prototyping in Product Development guide offers comprehensive guidance on leveraging these advanced manufacturing techniques.

Sheet metal fabrication has emerged as a transformative manufacturing technique, bridging innovation across diverse industrial sectors from cutting-edge aerospace engineering to precision medical device production. The versatility of sheet metal processing enables manufacturers to develop complex, high-performance components that meet stringent technical requirements.

Wikipedia highlights the automotive industry's extensive use of deep drawing techniques, particularly for manufacturing critical components like car bodies and fuel tanks. This process allows engineers to create intricate, deep-drawn components essential to modern vehicle design, demonstrating the remarkable precision and adaptability of sheet metal fabrication methodologies.

Wikipedia further illustrates the material innovation potential through aluminized steel, which combines fundamental steel strength with enhanced corrosion resistance. Such advanced materials find applications across multiple domains, including heat exchangers in residential furnaces, automotive mufflers, industrial ovens, and specialised water heating systems.

Key industry applications for sheet metal fabrication include:

For comprehensive insights into advanced manufacturing techniques, our 3D Printing in Aerospace Applications guide offers an in-depth exploration of contemporary engineering solutions.

Sheet metal fabrication encompasses a diverse range of manufacturing techniques, each with unique capabilities, advantages, and limitations. Engineers and designers must carefully evaluate these alternative processes to select the most appropriate method for their specific project requirements and constraints.

Wikipedia introduces rubber pad forming as an innovative deep drawing technique particularly suited for small to medium-sized production series. This method offers significant advantages over traditional deep drawing, including reduced tooling expenses and enhanced flexibility in producing complex geometrical shapes without dedicated dies. Manufacturers can achieve superior function integration and weight reduction through this advanced fabrication approach.

Wikipedia highlights ultrasonic consolidation (UC) as a groundbreaking low-temperature additive manufacturing technique. Unlike conventional sheet metal fabrication processes, UC enables joining metal foils through ultrasonic vibrations under pressure, presenting unique capabilities such as embedding temperature-sensitive materials and facilitating joins between dissimilar metals without substantial intermetallic formation.

Key alternative sheet metal fabrication methods include:

To explore comprehensive market perspectives on manufacturing technologies, our Market Insights for Precision Metal Parts Manufacturing guide provides in-depth analysis of emerging fabrication strategies.

Sheet metal fabrication demands a sophisticated balance between economic efficiency, production velocity, and manufacturing precision. Engineers and procurement managers must navigate complex trade-offs that impact product development timelines, budgetary constraints, and final component performance.

ArXiv highlights the transformative potential of process automation in sheet metal production. By integrating advanced mechatronics systems into manufacturing workflows, companies can dramatically enhance efficiency, consistency, and overall product quality. This technological approach substantially reduces manual interventions, leading to improved productivity and more predictable manufacturing outcomes.

ArXiv further demonstrates the strategic advantages of two-point incremental forming (TPIF), which offers unprecedented flexibility in sheet metal manufacturing. This innovative technique enables the production of complex geometrical shapes without requiring expensive dedicated dies, thereby reducing tooling costs and accelerating prototyping cycles. TPIF's ability to improve dimensional accuracy and material thickness distribution makes it particularly attractive for low-volume production environments.

Key considerations in evaluating sheet metal fabrication strategies include:

To explore strategies for optimising manufacturing economics, our 3D Printing Price in China guide provides nuanced insights into managing production costs effectively.

Navigating the complexities of sheet metal fabrication requires solutions that address challenges such as achieving exact geometric shapes, maintaining material integrity, and controlling costs during prototyping and production. If you seek to overcome issues like managing deep drawing or utilising advanced forming techniques such as two-point incremental forming, it is vital to partner with a manufacturer that excels in flexibility, high quality, and speed.

At WJ Prototypes, we offer an extensive range of sheet metal fabrication services designed to meet these precise industry demands. Whether you require rapid prototyping or small to medium production runs, our expert engineers leverage state-of-the-art processes combined with a variety of metals to ensure your complex designs become reality effortlessly. Discover how our sheet metal fabrication expertise can transform your next project with exceptional cost efficiency and unmatched precision.

Take the next step in optimising your manufacturing workflow. Explore the full scope of solutions on WJ Prototypes and accelerate your product development with partners who understand your challenges and deliver results on time.

The primary processes in sheet metal fabrication include cutting (laser, plasma, mechanical), forming (bending, rolling, stretching), joining (welding, riveting, fastening), and finishing (surface treatments for aesthetics and protection).

Common materials used in sheet metal fabrication include carbon steel, aluminium, stainless steel, copper, titanium, and brass, each offering distinct properties suitable for various industrial applications.

Sheet metal fabrication allows for rapid iteration and quick design modifications, cost efficiency through reduced tooling expenses, versatility in material usage, and the creation of complex geometries. Techniques like two-point incremental forming enhance these benefits by improving flexibility and accuracy.

Sheet metal fabrication is used across various industries, including aerospace (lightweight structural components), medical devices (surgical instrument housings), automotive (vehicle body panels), electronics (computer enclosures), and robotics (precision mechanical frameworks).