- Room 1807, Unit 9, Building 2, Shangxing Commercial Street, Shangde Road, Shangxing Community, Xinqiao Subdistrict, Bao'an District, Shenzhen City, China

Aerospace & UAV

WJ Prototypes is your 3D manufacturing partner from prototype to large scale production.

Consumer Electronics

New Product Introduction Solutions for Consumer Electronics.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Automotive

New Product Introduction Solutions for Automotive

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

Designing a new automotive component often means chasing absolute precision without sacrificing efficiency. Facing tight project timelines, engineers in the United States and Europe are turning to CNC machining in China for rapid prototyping and low-volume parts production. CNC machining delivers unmatched accuracy using automated, computer-controlled tools capable of producing intricate shapes and consistent quality from diverse materials. This guide clarifies CNC processes, machine selection, and workflow considerations that matter most for robust automotive engineering.

| Point | Details |

|---|---|

| CNC Machining Revolutionizes Automotive Production | CNC machining provides unmatched precision and consistency in producing complex automotive parts, enhancing manufacturing efficiency. |

| Technological Integration is Key | The use of machine learning in CNC systems optimizes processes, reduces errors, and improves production efficiency in automotive manufacturing. |

| Quality Assurance is Essential | Adhering to rigorous certification standards ensures reliable production and compliance with international automotive quality benchmarks. |

| Cost Management is Critical | Understanding and optimizing cost factors such as material selection and machine complexity can significantly impact overall manufacturing expenses. |

CNC machining has revolutionized automotive manufacturing, enabling precision production of complex parts with unprecedented accuracy. Unlike traditional manufacturing methods, advanced automation in CNC turning allows manufacturers to create intricate automotive components with minimal human intervention.

The core advantage of CNC machining in automotive production lies in its ability to consistently reproduce exact specifications across multiple parts. Modern automotive engineering demands extremely tight tolerances, and CNC machines deliver remarkable precision by utilizing computer-controlled cutting tools that move across multiple axes simultaneously. These machines can work with various materials including aluminum, steel, titanium, and specialized automotive-grade alloys.

Key capabilities of CNC machining for automotive parts include:

Technological Integration represents the future of automotive manufacturing. Modern CNC systems now incorporate machine learning algorithms that can autonomously adjust machining parameters, optimize cutting strategies, and predict potential tool wear - dramatically reducing production downtime and improving overall manufacturing efficiency.

Pro tip: When selecting a CNC machining partner for automotive parts, prioritize manufacturers with proven experience in automotive-grade precision engineering and comprehensive quality control processes.

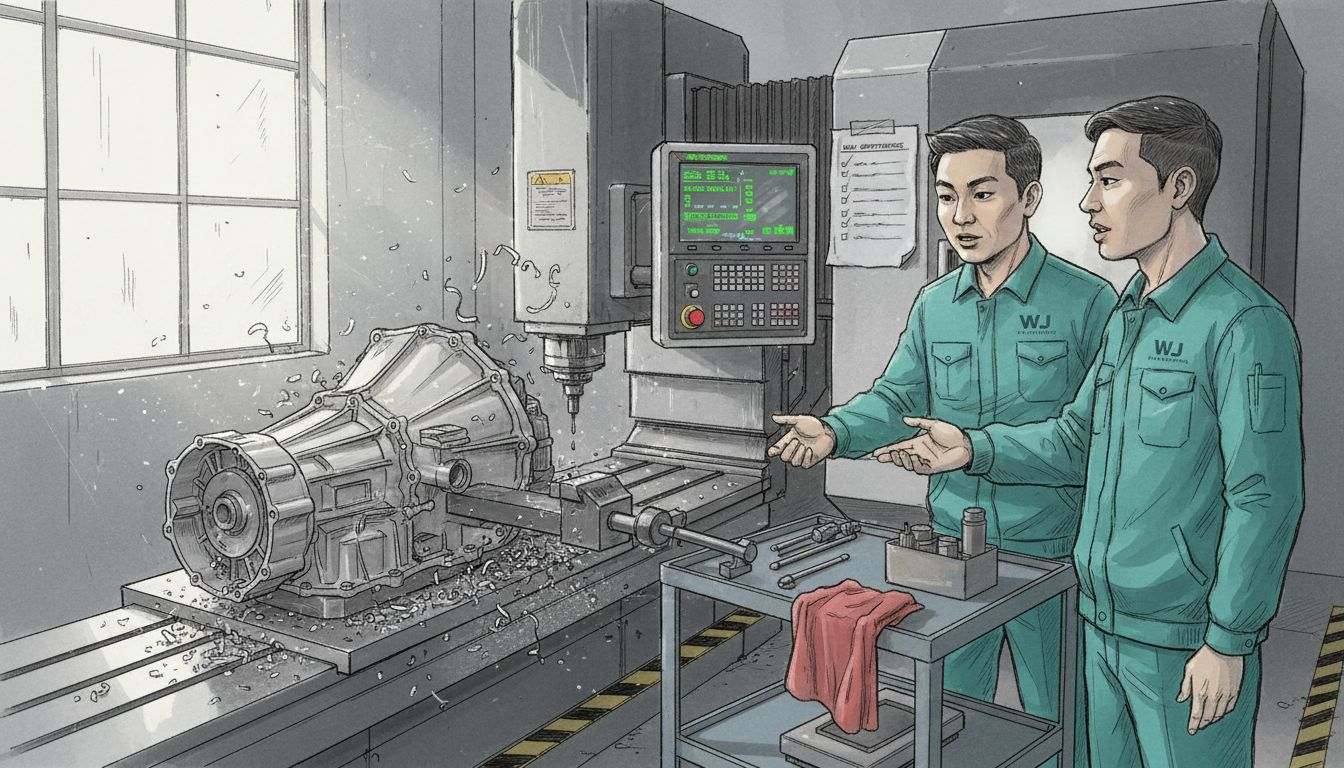

Modern automotive manufacturing relies on a diverse range of CNC machine types with specialized capabilities. These precision instruments transform raw materials into complex automotive components with extraordinary accuracy and repeatability, representing the technological backbone of contemporary automotive engineering.

Key CNC Machine Categories for automotive parts production include:

Each machine type offers unique advantages in automotive manufacturing. Milling machines excel at creating complex geometric shapes with tight tolerances, while turning lathes specialize in producing round or cylindrical components like shafts, bearings, and engine parts. Multiaxis machines represent the pinnacle of precision, capable of creating exceptionally complex parts that would be impossible with traditional manufacturing methods.

Here's a comparison of CNC machine types and their ideal automotive applications:

| Machine Type | Typical Parts Produced | Strength in Automotive Use |

|---|---|---|

| Milling Machine | Engine housings, brackets | Precise 3D shapes, tight tolerances |

| Turning Lathe | Shafts, bushings, pistons | Perfect for round components |

| Multiaxis Machine | Complex manifolds, gearboxes | Highly intricate geometries |

| Wire EDM | Injection molds, dies | Cuts hard materials accurately |

| Laser Cutter | Body panels, interior trim | High speed for thin materials |

Technological Advancement in CNC machining continues to push manufacturing boundaries. Modern machines integrate advanced computer controls, real-time monitoring systems, and adaptive learning algorithms that optimize cutting strategies, reduce material waste, and enhance overall production efficiency.

Pro tip: When selecting CNC machinery for automotive part production, prioritize machines with multiple axis capabilities and advanced computational control systems to maximize manufacturing flexibility and precision.

Automotive parts machining is a complex process that demands precision and systematic execution. Optimizing milling parameters represents a critical foundation for producing high-quality automotive components with exceptional accuracy and repeatability.

Key Machining Steps for automotive parts production include:

Precision in automotive machining demands meticulous attention to multiple critical parameters. Manufacturers must carefully control variables such as cutting speed, feed rate, and tool geometry to ensure consistent part quality. Modern CNC machines enable complex multi-axis machining that can create intricate geometries previously impossible with traditional manufacturing techniques.

This table summarizes how technology enhances each stage of the automotive CNC machining process:

| Production Step | Technological Enhancement | Resulting Benefit |

|---|---|---|

| Design Preparation | Advanced CAD software | Faster modeling, fewer errors |

| Programming | Automated tool path creation | Optimized machining paths |

| Machining | Real-time sensor feedback | Improved quality, fewer defects |

| Inspection | Digital metrology | Precise, consistent verification |

| Cost Control | Predictive analytics | Early detection of overruns |

Technological Precision drives automotive parts manufacturing forward. Advanced computational systems now allow real-time monitoring and automatic adjustments during machining, dramatically reducing human error and improving overall production efficiency.

Pro tip: Invest in comprehensive training for CNC programmers, ensuring they understand both mechanical principles and sophisticated software control systems to maximize manufacturing precision.

The automotive manufacturing industry demands rigorous quality management systems and global certification standards to ensure consistent, reliable production of automotive components. These comprehensive frameworks establish critical benchmarks for manufacturers seeking to meet international performance and safety requirements.

Key Quality Certification Standards in automotive manufacturing include:

Manufacturers must navigate a complex landscape of quality requirements that extend far beyond basic technical specifications. Compliance involves comprehensive documentation, rigorous testing protocols, and continuous improvement processes that systematically validate every aspect of automotive part production. Advanced certification standards now incorporate sophisticated metrics that evaluate not just product quality, but entire manufacturing ecosystems.

Technological Verification has transformed quality assurance through advanced computational tools and real-time monitoring systems. Modern certification processes leverage data analytics, machine learning algorithms, and predictive maintenance technologies to ensure unprecedented levels of precision and reliability in automotive parts manufacturing.

Pro tip: Implement a robust internal audit system that continuously benchmarks your quality management processes against the latest international certification standards to maintain competitive manufacturing excellence.

Optimizing CNC machining parameters plays a critical role in managing manufacturing costs for automotive parts. Understanding the complex financial landscape of precision manufacturing requires a strategic approach that balances technological capabilities with economic constraints.

Primary Cost Drivers in automotive CNC machining include:

Manufacturers frequently underestimate the nuanced expenses associated with automotive parts production. Beyond direct machining costs, hidden expenses emerge through inefficient programming, excessive tool changes, and inadequate process optimization. Comprehensive cost analysis must account for setup time, programming complexity, material consumption, and potential rework expenses.

Technological Cost Management represents a critical strategic approach. Advanced computational tools now enable predictive cost modeling, allowing manufacturers to simulate and optimize machining processes before actual production, dramatically reducing potential financial risks and unexpected expenditures.

Pro tip: Develop a comprehensive cost tracking system that captures both direct and indirect expenses, enabling granular insights into your manufacturing economic performance.

Navigating the complexities of automotive parts manufacturing demands not only cutting-edge CNC machining expertise but also a trusted partner who understands the intricacies of materials, multi-axis machining, and stringent quality standards like IATF 16949. If you are seeking to overcome challenges such as maintaining micron-level accuracy, reducing costly tool wear, and ensuring consistent production quality, WJ Prototypes offers tailored solutions that perfectly align with these automotive industry needs.

Leverage our ISO certified facility based in China for high-quality, cost-effective CNC machining services designed for rapid prototyping and small to medium production runs. Experience the advantage of advanced automotive-grade precision engineering combined with fast turnaround times. Discover more about how our comprehensive manufacturing capabilities can accelerate your project from design to market by visiting WJ Prototypes. Ready to optimize your CNC machining strategy and achieve unparalleled consistency? Contact us now to get a custom quote and bring your automotive components to life with expert care and technical excellence.

CNC machining is a manufacturing process where computer-controlled cutting tools create complex automotive components with high precision. This method allows manufacturers to produce intricate parts with tight tolerances and consistent quality.

Common CNC machines used in automotive manufacturing include milling machines, turning lathes, multiaxis machines, wire EDM, and laser cutting machines. Each type is designed for specific applications, such as creating complex shapes or precise cylindrical components.

Technological advancements in CNC machining include the incorporation of machine learning algorithms and real-time monitoring systems. These innovations optimize machining processes, reduce tool wear, and enhance efficiency, leading to improved quality and reduced production downtime.

Key quality assurance standards in automotive CNC machining include IATF 16949:2016, ISO 9001, and PPAP. These standards ensure consistent quality and reliability through rigorous testing and documentation processes, establishing benchmarks for manufacturers to meet international safety and performance requirements.

Custom CNC Machining in China | From Prototype to Production

Chinese CNC Machining | Precision, Quality & Value

Complete Guide to the Role of CNC Machining - WJ Prototypes

Automotive Prototyping in China | Why China Leads the Industry