- Room 1807, Unit 9, Building 2, Shangxing Commercial Street, Shangde Road, Shangxing Community, Xinqiao Subdistrict, Bao'an District, Shenzhen City, China

Aerospace & UAV

WJ Prototypes is your 3D manufacturing partner from prototype to large scale production.

Consumer Electronics

New Product Introduction Solutions for Consumer Electronics.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Automotive

New Product Introduction Solutions for Automotive

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

Most british and Canadian product engineers know that over one-third of all polymers worldwide are converted into functional parts through plastic injection moulding. This method plays a powerful role in speeding up prototype development and achieving low-volume production with accuracy and repeatability. If you design automotive or aerospace components, understanding the fundamentals of injection moulding could save valuable time while ensuring reliable quality across every production batch.

| Point | Details |

|---|---|

| Plastic Injection Moulding Efficiency | The process enables quick production of intricate parts with minimal waste and high repeatability. |

| OEM Manufacturing Flexibility | Custom manufacturing allows for tailored solutions across multiple industries, ensuring high-performance outputs. |

| Quality Assurance Standards | Adhering to international standards like ISO 9001 enhances product quality and reliability. |

| Cost Management Strategies | Understanding total costs and clear communication can mitigate risks in international manufacturing. |

Plastic injection moulding is a sophisticated manufacturing process where molten polymer materials are transformed into precise, complex components with remarkable efficiency. This advanced technique allows engineers and manufacturers to create intricate parts by injecting heated polymers into specialised moulds, enabling rapid production with exceptional consistency and detail.

The process involves several critical stages that distinguish it from other manufacturing methods. Initially, raw plastic granules are heated to their melting point, typically between 200 to 400 degrees Celsius, creating a molten liquid with excellent flow characteristics. This liquefied material is then forcefully injected into a carefully designed metal mould cavity under high pressure, ensuring every microscopic detail of the intended design is captured. Once injected, the material rapidly cools and solidifies, taking the precise shape of the mould before being ejected as a finished component.

Manufacturers globally rely on injection moulding for producing everything from automotive parts to medical devices, highlighting its versatility. The technique transforms approximately one-third of all polymers into functional parts, making it a cornerstone of modern manufacturing. Key advantages include high repeatability, minimal material waste, and the ability to create complex geometries that would be challenging or impossible with traditional manufacturing techniques.

Here's a summary of key injection moulding advantages and their impact on manufacturing:

| Advantage | Description | Business Impact |

|---|---|---|

| High repeatability | Consistent production quality | Reduces defects and rejects |

| Minimal material waste | Efficient use of resources | Lowers production costs |

| Complex geometric production | Detailed, intricate part capability | Enables innovative product design |

| Rapid cycle times | Fast part creation | Accelerates time-to-market |

Pro tip:When selecting materials for injection moulding, consider not just the mechanical properties, but also the thermal stability and flow characteristics to ensure optimal part performance.

Original Equipment Manufacturer (OEM) services represent a critical capability for businesses seeking precision-engineered plastic components across multiple industries. These specialised manufacturing services enable companies to develop custom injection moulding solutions for automotive and consumer electronics sectors, transforming complex design requirements into tangible, high-performance products.

Custom manufacturing capabilities extend far beyond standard production runs. Manufacturers specialising in OEM services must demonstrate exceptional flexibility, technical expertise, and the ability to interpret intricate engineering specifications. This involves comprehensive processes including initial design consultation, prototype development, material selection, tooling fabrication, precise injection moulding, quality control, and final component delivery. Advanced facilities in China have developed sophisticated workflows that can accommodate everything from small-batch prototyping to large-scale industrial production runs.

The most sophisticated OEM providers offer end-to-end manufacturing solutions that integrate multiple production technologies. These comprehensive services typically include computer-aided design (CAD) support, rapid prototyping, precision injection moulding, surface finishing, and advanced quality assurance protocols. By providing such integrated approaches, manufacturers can significantly reduce development timelines, minimise production costs, and ensure consistently high-quality output across diverse industrial applications.

Pro tip:When selecting an OEM manufacturing partner, prioritise providers with proven cross-industry experience and robust quality management systems that can demonstrate verifiable technical capabilities.

Quality assurance represents the foundational cornerstone of precision manufacturing, particularly in plastic injection moulding. Comprehensive quality control processes encompass four critical stages, ensuring that every component meets exacting international standards and client specifications.

In the context of Chinese manufacturing, quality assurance extends well beyond basic inspection protocols. Advanced facilities implement sophisticated multi-stage verification processes that begin with meticulous design review and continue through detailed mould inspection, rigorous in-process quality control, and comprehensive final product evaluation. Critical elements such as material selection, precision mould design, machine calibration, process control, and systematic personnel training collectively contribute to minimising manufacturing defects and maintaining consistently superior product quality.

The most advanced Chinese manufacturing centres have adopted international certification standards, including ISO 9001 quality management systems, which provide a robust framework for ensuring technical excellence. These standards mandate comprehensive documentation, traceability, continuous improvement protocols, and systematic performance monitoring. By integrating advanced technological capabilities with structured quality management approaches, Chinese manufacturers can deliver high-precision components that meet the most demanding global engineering specifications across automotive, electronics, medical, and industrial sectors.

Pro tip:Request detailed quality control documentation and statistical process control (SPC) reports to validate a manufacturer's genuine commitment to consistent product excellence.

In the competitive landscape of global manufacturing, production speed emerges as a critical differentiator for businesses seeking rapid prototype development and efficient component production. Manufacturers in China have developed sophisticated strategies to minimise lead times while maintaining exceptional quality standards across diverse industrial sectors.

Global logistics in modern manufacturing represent a complex ecosystem of interconnected processes, technological infrastructure, and strategic planning. Advanced Chinese manufacturing facilities leverage cutting-edge technologies and streamlined workflows to compress production timelines, typically reducing prototype development cycles from weeks to mere days. This acceleration is achieved through integrated design systems, advanced rapid prototyping technologies, simultaneous engineering approaches, and highly optimised manufacturing workflows that eliminate traditional bottlenecks and inefficiencies.

International manufacturers increasingly recognise the strategic advantages of Chinese production capabilities, which combine rapid turnaround times with competitive pricing and sophisticated engineering expertise. The most advanced facilities offer comprehensive logistics solutions that include instant online quotation systems, real-time project tracking, flexible shipping options, and seamless global delivery networks. These capabilities enable businesses to transform product concepts into market-ready components with unprecedented speed and precision, effectively reducing time-to-market and supporting aggressive product development strategies.

Pro tip:Request detailed production timeline projections and establish clear communication protocols to ensure alignment between your product development schedule and manufacturing capabilities.

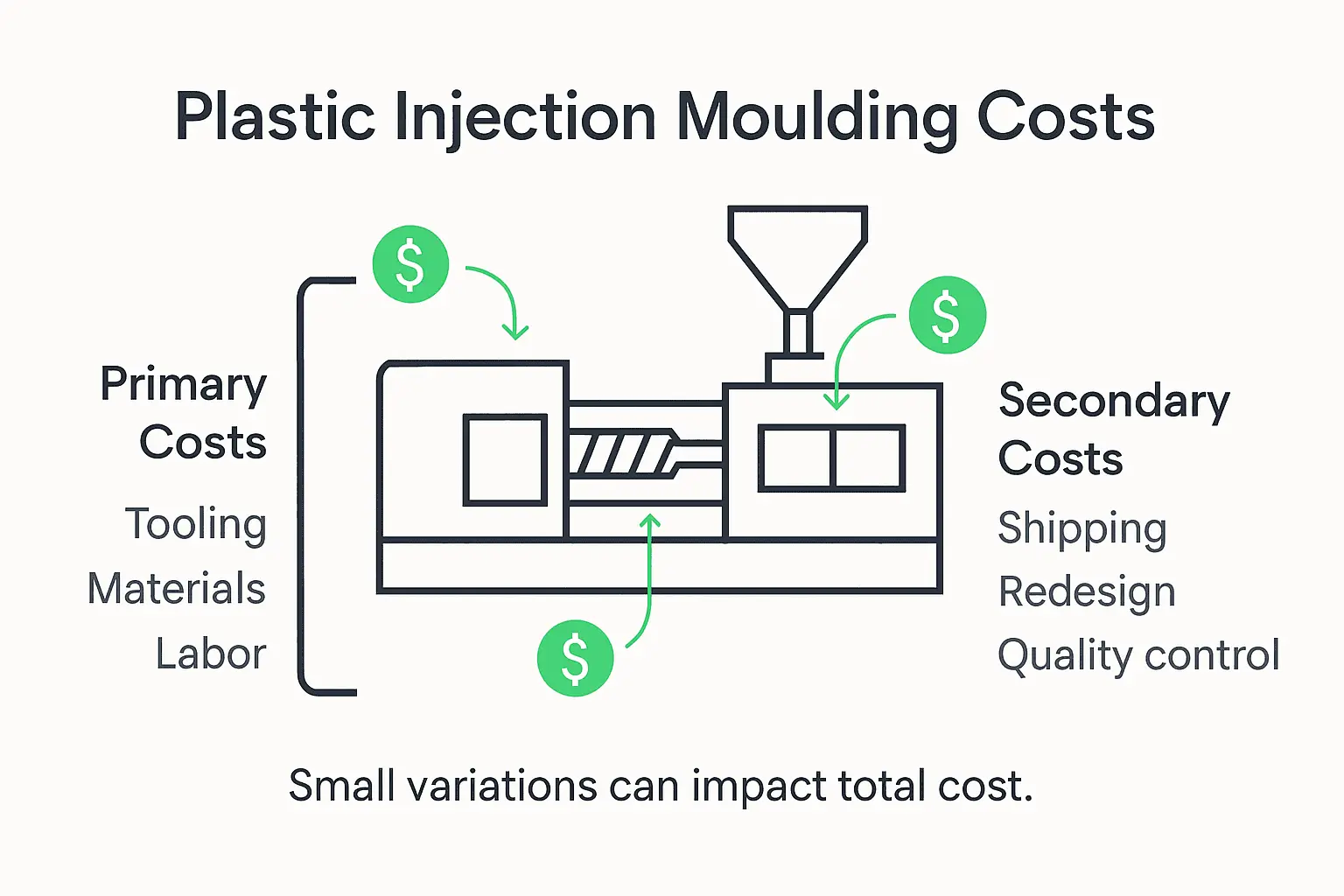

Cost management represents a critical strategic consideration for organisations seeking plastic injection moulding services in China. Manufacturers can optimise their prototyping expenditure by understanding nuanced pricing structures and implementing sophisticated procurement strategies that balance quality, speed, and economic efficiency.

Navigating the complex landscape of international manufacturing requires a sophisticated approach to cost evaluation. Beyond simple price comparisons, successful organisations consider total cost of ownership, which encompasses tooling expenses, material selection, production volume, design complexity, surface finishing requirements, and potential redesign costs. Advanced Chinese manufacturers offer transparent pricing models that break down individual cost components, enabling engineering teams to make data-driven decisions and identify potential areas for economic optimisation.

Common pitfalls in international manufacturing procurement often stem from inadequate communication, unrealistic expectations, and insufficient technical specification clarity. Successful organisations mitigate these risks by establishing comprehensive initial consultations, developing detailed technical specifications, requesting comprehensive prototype evaluations, and maintaining ongoing communication channels. By implementing rigorous vendor assessment protocols, conducting thorough quality audits, and establishing clear performance metrics, manufacturers can effectively manage potential risks associated with international production partnerships.

The following table compares typical cost factors in Chinese plastic injection moulding projects:

| Cost Factor | Typical Range | Importance for Buyers |

|---|---|---|

| Tooling expenses | £2,000–£20,000 per mould | Major upfront investment |

| Material costs | £1–£5 per kg | Can vary by polymer type |

| Labour charges | £10–£30 per hour | Influences total project cost |

| Finishing/Redesign | £100–£2,000 per project | Necessary for premium requirements |

| Quality audits | £500–£2,500 per audit | Ensures compliance and reliability |

Pro tip:Request comprehensive cost breakdowns that include tooling expenses, material costs, labour, and potential redesign requirements to develop a holistic understanding of your project's economic landscape.

Navigating the complexities of plastic injection moulding in China requires a partner who understands the importance of high repeatability, quality assurance, and rapid production. The challenges of maintaining consistent component quality, optimising costs, and meeting tight delivery timelines are critical for OEMs aiming to transform innovative designs into market-ready products. At WJ Prototypes, we specialise in addressing these exact pain points by offering precision injection moulding supported by expert material selection, detailed quality controls, and streamlined manufacturing workflows.

Our ISO certified manufacturing facility in China excels at delivering fast and reliable prototyping as well as low to medium volume production runs. With cutting-edge technologies and a broad range of services including injection moulding and CNC machining, we empower businesses across automotive, medical, and electronics sectors to accelerate product development without compromising quality. Discover how our comprehensive approach can help you avoid costly pitfalls and keep your projects on track by exploring WJ Prototypes manufacturing solutions.

Ready to transform your OEM plastic injection moulding challenges into competitive advantages? Visit WJ Prototypes today to request an instant quote, explore our quality assurance policies, and start accelerating your path from design to delivery with confidence.

Plastic injection moulding is a manufacturing process that involves injecting molten polymer materials into specially designed moulds to create precise and complex components efficiently.

Key advantages of plastic injection moulding include high repeatability, minimal material waste, the ability to create complex geometries, and rapid cycle times, which all contribute to lower production costs and enhanced product design capabilities.

OEM services provide customised solutions that involve design consultation, prototype development, and quality assurance, enabling manufacturers to meet specific engineering requirements across various industries effectively.

When communicating with a manufacturer, consider establishing clear technical specifications, requesting detailed cost breakdowns, and ensuring ongoing communication channels to align on production timelines and quality expectations.