- Room 1807, Unit 9, Building 2, Shangxing Commercial Street, Shangde Road, Shangxing Community, Xinqiao Subdistrict, Bao'an District, Shenzhen City, China

Aerospace & UAV

WJ Prototypes is your 3D manufacturing partner from prototype to large scale production.

Consumer Electronics

New Product Introduction Solutions for Consumer Electronics.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Automotive

New Product Introduction Solutions for Automotive

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

Every tight project timeline leaves engineers weighing how material choice can speed up development without causing costly setbacks. For product teams in aerospace and automotive fields, selecting the right prototyping material is much more than ticking a box. As the backbone of a prototype’s performance and cost efficiency, material selection greatly influences design reliability and manufacturing success. This overview reveals how understanding core material properties empowers quicker concept validation and leaner production cycles.

| Point | Details |

|---|---|

| Material Selection is Critical | Choosing the right materials substantially affects prototype performance, durability, and production feasibility. |

| Evaluate Key Properties | Systematic analysis of mechanical, thermal, and chemical properties is essential to align materials with design requirements. |

| Consider Cost and Risks | Balancing material quality with budget constraints is vital; unexpected material performance failures can lead to significant project delays and costs. |

| Conduct Performance Testing | Rigorous small-scale tests and simulations should be performed to validate material choices against real-world operational conditions. |

In product development, material selection critically influences prototype performance across multiple engineering domains. Materials serve as the fundamental building blocks determining a prototype's functional characteristics, durability, and manufacturing feasibility.

Engineering prototypes require strategic material choices that balance multiple competing requirements. Designers must consider factors like mechanical strength, thermal resistance, cost, weight, and manufacturing complexity when selecting appropriate materials. These considerations transform raw materials from passive components into active design enablers that directly impact product performance and development trajectory.

The prototype material determines not just the physical representation but also simulates real-world performance expectations. Advanced prototyping methodologies leverage materials that can closely mimic final product behaviours, allowing engineers to validate design concepts with remarkable precision. Physical prototyping rationales depend fundamentally on material properties, enabling comprehensive functional evaluations before full-scale production.

Pro tip:When selecting prototype materials, always conduct small-scale performance tests to validate material compatibility with your specific design requirements and anticipated manufacturing processes.

Prototyping materials offer diverse capabilities that directly influence product development strategies. Understanding the unique characteristics of different material types enables engineers to select optimal solutions for specific design requirements, balancing performance, cost, and manufacturing complexity.

Three primary material categories dominate prototyping applications: plastics, metals, and composites. Plastics provide exceptional versatility, offering lightweight properties and cost-effectiveness for preliminary design iterations. Thermoplastics like ABS, polycarbonate, and polyethylene enable rapid prototyping with excellent dimensional stability and relatively low production expenses. Metals such as aluminium, steel, and titanium deliver superior strength and durability, making them ideal for functional prototypes requiring robust mechanical performance.

Composite materials represent a sophisticated category bridging multiple performance characteristics. These engineered materials combine different substances to create enhanced properties, allowing designers to develop prototypes with specialised characteristics like high strength-to-weight ratios, improved thermal resistance, and tailored mechanical behaviours. Advanced composite solutions include carbon fibre reinforced polymers, fibreglass, and ceramic composites, each offering unique advantages for specific engineering challenges.

The following table compares core categories of prototyping materials based on typical applications and advantages:

| Material Type | Common Applications | Key Advantages |

|---|---|---|

| Plastics | Early prototypes, consumer goods | Low cost, easy to shape |

| Metals | Functional parts, automotive and aerospace | High strength, good durability |

| Composites | Aerospace, sports equipment, high-performance products | Excellent strength-to-weight ratio, customisable properties |

Pro tip:Select prototype materials by systematically mapping their intrinsic properties against your specific design performance requirements, ensuring optimal alignment between material characteristics and functional expectations.

Material selection demands comprehensive evaluation of multiple critical performance parameters. Engineers must systematically analyse mechanical properties, manufacturing constraints, cost implications, and environmental interactions to develop prototypes that accurately represent final product expectations.

Mechanical properties represent the foundational consideration in material selection. Strength, flexibility, durability, and load-bearing capacity directly influence prototype performance and testing outcomes. Designers must carefully assess tensile strength, compressive resistance, impact resilience, and fatigue characteristics to ensure the selected material can withstand anticipated operational stresses. Advanced engineering requires understanding nuanced material behaviours under different loading conditions, temperature ranges, and mechanical interactions.

Beyond mechanical considerations, material selection involves complex performance criteria including thermal stability, chemical resistance, and aesthetic qualities. Thermal behaviour determines a material's performance under varying temperature conditions, while chemical resistance ensures prototype integrity when exposed to different environmental factors. Aesthetic considerations become particularly crucial in industries like consumer electronics and automotive design, where visual and tactile qualities significantly impact user perception and product success.

Pro tip:Create a comprehensive material selection matrix that quantitatively scores potential materials against your specific project requirements, enabling systematic and objective evaluation of competing material options.

Material selection plays a critical role in aerospace and automotive engineering, where performance requirements demand exceptional precision and reliability. These industries require prototype materials that can withstand extreme conditions while maintaining structural integrity, lightweight characteristics, and superior mechanical properties.

In aerospace applications, engineers prioritise materials that deliver extraordinary strength-to-weight ratios. Titanium alloys and advanced carbon fibre composites dominate prototype development, offering remarkable durability and resistance to temperature fluctuations. These materials enable the creation of complex aerospace components that must perform consistently in challenging environments, from high-altitude commercial aircraft structures to intricate spacecraft components requiring minimal weight and maximum structural resilience.

Automotive prototyping similarly demands sophisticated material strategies, focusing on innovations that reduce vehicle weight while maintaining safety and performance standards. Advanced aluminium alloys, high-strength steel composites, and engineered polymer materials enable automotive designers to create prototypes that simulate real-world performance characteristics. The continuous evolution of material science allows manufacturers to develop increasingly lightweight, fuel-efficient vehicles with enhanced structural integrity and improved crash resistance.

Pro tip:Conduct comprehensive material performance simulations that replicate actual operational conditions before finalising prototype material selections, ensuring comprehensive validation across multiple performance parameters.

Prototyping material selection involves substantial financial and technical risks that can significantly impact overall project success. Engineers must navigate complex challenges related to material performance, manufacturing compatibility, and budgetary constraints to develop effective prototypes.

Unexpected material performance failures represent a critical risk in prototyping. Common pitfalls include selecting materials with inadequate mechanical properties, poor thermal stability, or limited environmental resistance. These errors can lead to prototype redesigns, extended development timelines, and substantial financial losses. Designers must conduct rigorous material property assessments, including comprehensive stress testing, thermal cycling evaluations, and long-term durability simulations to mitigate potential performance risks.

Cost considerations form another crucial dimension of material selection challenges. Prototyping strategies require careful cost-benefit analysis to balance material quality with budgetary limitations. High-performance materials often carry premium pricing, necessitating strategic trade-offs between prototype fidelity and overall project economics. Unexpected material processing complexities can exponentially increase development expenses, making comprehensive preliminary research essential for maintaining financial control.

Here is a summary of key risks encountered during prototyping material selection and effective mitigation strategies:

| Common Risk | Example Scenario | Mitigation Strategy |

|---|---|---|

| Inadequate strength | Prototype fails under load | Perform stress simulations |

| High material cost | Premium metals or composites | Conduct cost-benefit analysis |

| Manufacturing challenges | Difficult to machine materials | Select more suitable alternatives |

Pro tip:Develop a comprehensive material evaluation matrix that quantitatively scores potential materials across performance, cost, and manufacturability parameters, enabling systematic risk mitigation during prototype development.

Understanding the crucial role materials play in prototyping can make the difference between costly delays and successful product development. This article highlights the challenges of balancing mechanical strength, cost, and manufacturing complexity while choosing the right materials to meet precise design requirements. At WJ Prototypes, we share your goals of optimising prototype performance and reducing time to market by offering a broad range of advanced manufacturing technologies paired with carefully selected materials tailored for aerospace, automotive, medical, and industrial applications.

Benefit from our expertise in materials like metals, composites and plastics to achieve prototypes that truly reflect your final product performance. Our services include SLA, SLS, MJF, DMLS, CNC machining and many more, delivering high-quality, fast, and cost-effective prototyping and low-volume production. Don’t let common material pitfalls or unexpected costs slow your progress. Explore how we can support your rapid product development by visiting WJ Prototypes today to request a quote and experience seamless collaboration from design to manufacturing.

Take control of your prototyping process now. Discover tailored material solutions and innovative fabrication methods designed to meet your exact specifications at WJ Prototypes. Your next breakthrough prototype is just a click away.

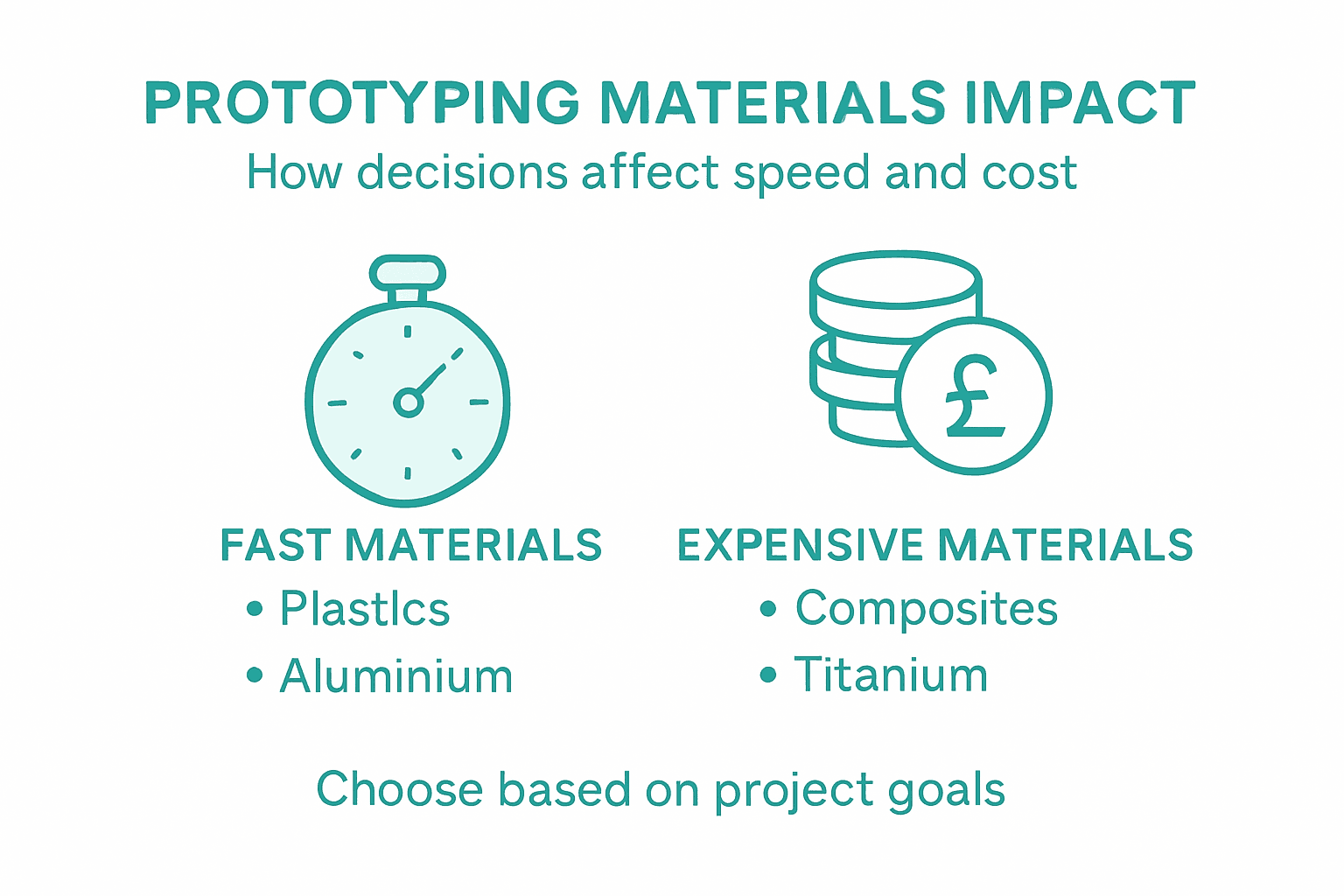

Material selection significantly impacts both speed and costs in prototyping. Choosing the right materials can reduce production time and expenses by enhancing manufacturing feasibility and ensuring that prototypes meet specific requirements without the need for costly redesigns.

The primary material categories used in prototyping include plastics, metals, and composites. Each has unique properties and applications, with plastics being lightweight and cost-effective, metals offering strength and durability, and composites providing enhanced performance characteristics.

Key properties to consider include mechanical strength, thermal stability, cost, weight, and manufacturing complexity. Evaluating these properties ensures that the selected material aligns with the prototype's performance expectations and end-use conditions.

Common risks include inadequate mechanical properties, high material costs, and manufacturing challenges. These risks can lead to prototype failures or increased expenses, making it essential to conduct thorough assessments and simulations during the material selection process.

Role of Materials in Prototyping | Sourcing Quality Materials from China

Material Selection in Prototyping from China | Key Material Choices

Guide To Cost-Effective Prototyping - Reducing Risks and Expenses

Fast Prototyping Turnaround in China | Speed Up Product Development

Understanding the Role of Fast Fashion Fabrics in Design