- Room 1807, Unit 9, Building 2, Shangxing Commercial Street, Shangde Road, Shangxing Community, Xinqiao Subdistrict, Bao'an District, Shenzhen City, China

Aerospace & UAV

WJ Prototypes is your 3D manufacturing partner from prototype to large scale production.

Consumer Electronics

New Product Introduction Solutions for Consumer Electronics.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Automotive

New Product Introduction Solutions for Automotive

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

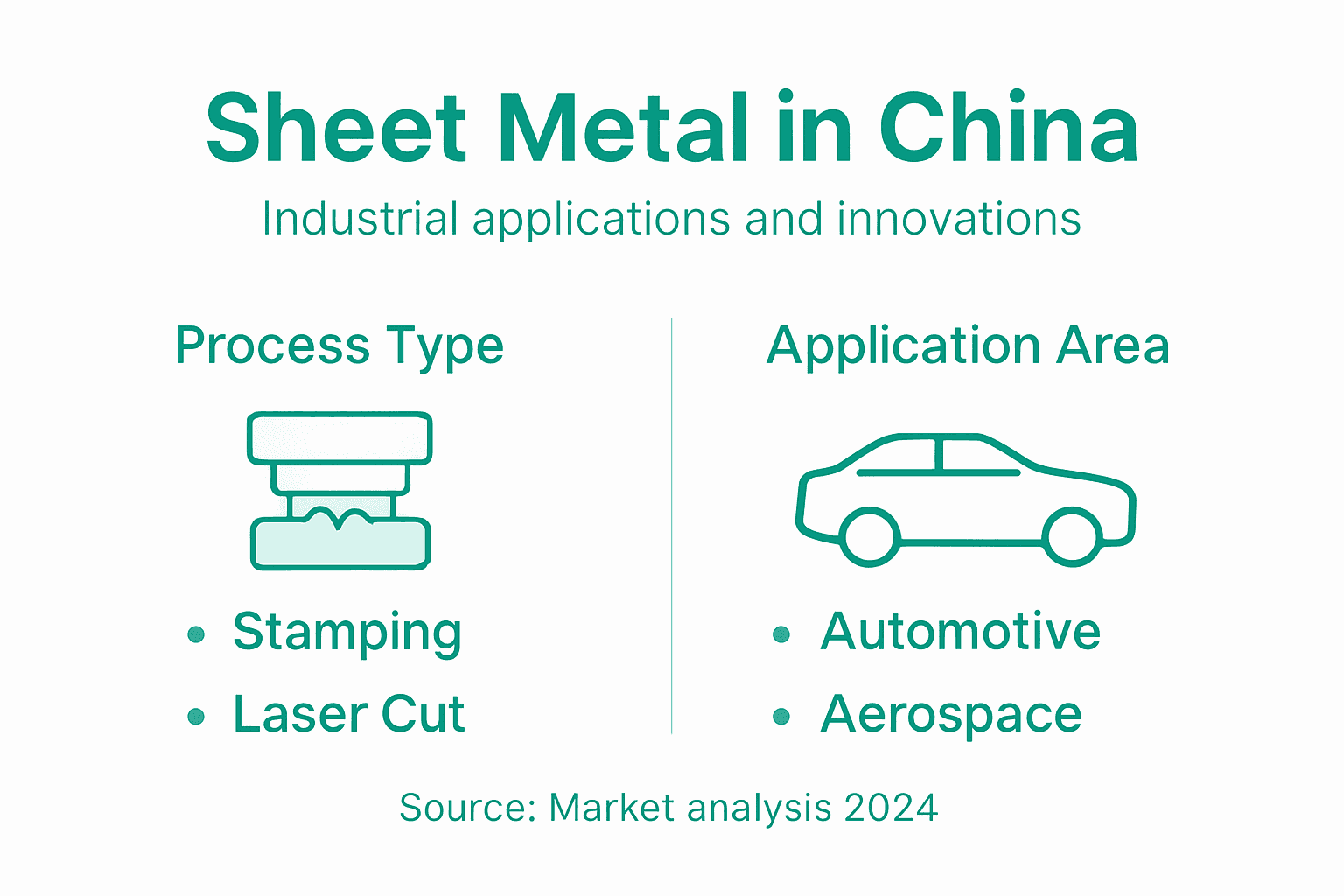

Rising material costs and strict precision demands often challenge manufacturing engineers working across the Asian aerospace and automotive fields. Sheet metal fabrication has rapidly evolved in China, bringing together advanced techniques like automated laser cutting and high-precision bending using steel, aluminum, and copper. By exploring the versatility of sheet metal fabrication and recent technological advancements in Chinese manufacturing, you can discover new pathways to streamline prototype development and achieve significant production cost savings.

| Point | Details |

|---|---|

| Importance of Sheet Metal Fabrication | Sheet metal fabrication in China is essential for creating high-precision components across various industries. |

| Advancements in Automation | Advanced technologies like CNC machines and AI integration are revolutionizing production processes, enhancing efficiency and quality. |

| Economic and Quality Benefits | Manufacturers experience significant cost reductions and improved quality through optimized processes and materials. |

| Application in Key Industries | Sheet metal fabrication is crucial for producing lightweight, durable components in the aerospace and automotive sectors. |

Sheet metal fabrication represents a critical manufacturing process in China that transforms flat metal sheets into precise, complex components through multiple advanced techniques. Sheet metal fabrication involves cutting, bending, forming, and assembling sheet metal into intricate products using diverse metallic materials.

The Chinese manufacturing landscape has rapidly evolved, integrating sophisticated technologies to enhance sheet metal fabrication capabilities. Key materials utilized in this process include:

Manufacturing techniques in China have become increasingly sophisticated, encompassing advanced processes like laser cutting, precision stamping, automated welding, and specialized finishing. These methods enable manufacturers to produce high-precision components for industries ranging from automotive and aerospace to electronics and medical equipment.

Industrial applications of sheet metal fabrication in China are diverse and complex. Manufacturers can transform raw metal sheets into everything from intricate machinery parts to large-scale architectural elements, demonstrating remarkable versatility and technological prowess.

Pro tip: Select sheet metal materials strategically by considering your specific project requirements, understanding each metal's unique mechanical properties and performance characteristics.

Sheet metal fabrication in China encompasses a sophisticated array of cutting-edge manufacturing processes that continuously push technological boundaries. Recent developments in sheet metal forming technologies have transformed the industry's capabilities, introducing innovative techniques that dramatically enhance manufacturing precision and efficiency.

The primary fabrication processes utilized in Chinese manufacturing include:

Advanced technological innovations have significantly expanded the potential of sheet metal fabrication. Manufacturers now employ sophisticated techniques like warm forming of magnesium alloys, hot stamping combined with quenching processes, and advanced crystal plasticity modeling to predict and control metal deformation with unprecedented accuracy.

Industrial applications of these technologies span multiple high-precision sectors, including automotive, aerospace, electronics, and medical equipment manufacturing. The ability to work with ultra-high-strength steels and complex alloy compositions has revolutionized component design and production capabilities.

Here's a summary of how key fabrication processes support major Chinese industries:

| Process | Precision Level | Major Application Area | Unique Benefit |

|---|---|---|---|

| Laser Cutting | Extremely High | Electronics | Minimal material waste |

| Stamping | High | Automotive | Fast complex shape formation |

| Welding | Very High | Aerospace | Exceptional structural integrity |

| Forming | High | Medical Equipment | Enhanced component geometry |

Pro tip: Evaluate your manufacturing process by considering material properties, desired geometric complexity, and required precision to select the most appropriate sheet metal fabrication technique.

The Chinese manufacturing landscape is experiencing a transformative shift through advanced factory automation technologies that are revolutionizing sheet metal production processes. These cutting-edge innovations are dramatically reshaping manufacturing efficiency, precision, and operational capabilities.

Key automation technologies driving this transformation include:

The primary objectives of these automation technologies center on minimizing human intervention while maximizing production speed and reducing operational errors. Manufacturers are implementing sophisticated systems that can continuously monitor production parameters, automatically adjust manufacturing processes, and generate comprehensive performance analytics in real-time.

Industrial implementation of these advanced automation technologies has created significant competitive advantages for Chinese manufacturers. By reducing labor costs, improving product consistency, and enabling more complex manufacturing techniques, these innovations are positioning China as a global leader in high-precision sheet metal fabrication.

Compare the impact of factory automation technologies in sheet metal production:

| Technology | Operational Benefit | Impact on Workforce | Competitive Advantage |

|---|---|---|---|

| CNC Machines | Consistent precision | Lower skill gap needed | Rapid design changes possible |

| Robotic Welding | Improved weld quality | Reduced manual labor | Higher throughput |

| AI Integration | Predictive maintenance | Upskilled technicians | Advanced quality management |

Pro tip: Prioritize gradual technology integration by first identifying specific production bottlenecks where automation can deliver the most immediate and measurable improvements.

China's sheet metal fabrication technologies are driving significant transformations in aerospace and automotive manufacturing through advanced metal forming innovations. These cutting-edge developments are creating unprecedented opportunities for producing lightweight, high-performance components that meet increasingly demanding industry specifications.

Key applications in these critical sectors include:

The development of ultra-high-strength steels and sophisticated warm forming processes has enabled manufacturers to create components with exceptional performance characteristics. These technological advancements support critical industry requirements such as improved fuel efficiency, enhanced safety standards, and reduced overall manufacturing costs.

Industrial precision in these sectors demands extraordinarily tight tolerances and consistent quality. Chinese manufacturers have positioned themselves as global leaders by continuously investing in research and development, integrating advanced computational modeling, and implementing state-of-the-art fabrication techniques that push the boundaries of traditional manufacturing limitations.

Pro tip: Prioritize material selection and forming techniques that balance weight reduction with structural integrity when designing aerospace and automotive components.

Sheet metal fabrication in China delivers remarkable value through advanced manufacturing technologies that dramatically reduce production expenses while maintaining exceptional quality standards. These sophisticated approaches enable manufacturers to optimize both economic and technical performance across complex industrial applications.

Key benefits and cost considerations include:

Manufacturers leverage sophisticated design principles like manufacturability and assembly optimization to counteract potential challenges from fluctuating raw material prices. By integrating computational modeling, automation, and strategic material selection, Chinese sheet metal fabrication facilities can deliver high-performance components with remarkable cost-effectiveness.

Industrial competitiveness in sheet metal fabrication hinges on balancing technological innovation with economic practicality. Chinese manufacturers have distinguished themselves by developing robust, adaptable production systems that can quickly respond to market demands while maintaining stringent quality control mechanisms.

Pro tip: Conduct regular cost-benefit analyses of your manufacturing technologies, focusing on total lifecycle expenses rather than just initial investment prices.

The insights from "Sheet Metal Fabrication in China: Trends and Innovations" reveal how critical precision, advanced automation, and material expertise are for overcoming manufacturing challenges in aerospace, automotive, and high-tech industries. If managing complex forming techniques, rapid prototyping needs, and cost-efficiency in low to medium volume production is a priority for you, then having a reliable manufacturing partner is essential. Understanding terms like laser cutting, robotic welding, and warm forming is one thing, but applying them effectively to achieve consistent quality and quick turnaround requires specialized experience.

At WJ Prototypes, we combine cutting-edge sheet metal fabrication technology with extensive expertise in CNC machining, SLA, SLS, and more to solve these exact challenges. Our streamlined processes reduce material waste and boost product precision, all while maintaining rapid delivery schedules. Whether your project demands ultra-high-strength steels or complex assembly-ready components, our advanced capabilities and ISO certification ensure your parts meet the highest industry standards. Stop risking costly delays or quality compromises by choosing proven professionals who understand your industry’s exact needs.

Discover how our professional manufacturing services can transform your component development and production workflow. Contact WJ Prototypes' sheet metal fabrication services today and take the first step toward faster, more precise, and cost-effective sheet metal fabrication tailored for your business.

Sheet metal fabrication is the manufacturing process that transforms flat metal sheets into precise components through techniques such as cutting, bending, forming, and assembling.

Key materials include steel for durability, aluminum for its lightweight properties, stainless steel for corrosion resistance, and copper for its excellent electrical conductivity.

The primary processes include laser cutting, stamping, welding, bending, and forming, each offering unique benefits tailored to specific industrial applications.

Automation technologies like CNC machines and robotic welding systems enhance precision, reduce human error, and increase efficiency in the manufacturing process, contributing to significant competitive advantages.

Role of Sheet Metal Fabrication - Complete Guide

Discover Market Insights for Precision Metal Parts Manufacturing

Why Use Sheet Metal Fabrication - Complete Guide for Industry

Sheet Metal Fabrication 101 | Step-by-Step Guide for Precision Parts