- Room 1807, Unit 9, Building 2, Shangxing Commercial Street, Shangde Road, Shangxing Community, Xinqiao Subdistrict, Bao'an District, Shenzhen City, China

Aerospace & UAV

WJ Prototypes is your 3D manufacturing partner from prototype to large scale production.

Consumer Electronics

New Product Introduction Solutions for Consumer Electronics.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Automotive

New Product Introduction Solutions for Automotive

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

Rapid iteration can slash product development timelines by more than 50 percent for aerospace and automotive teams. Whether you are a British engineer designing next-generation aircraft or an American developer crafting innovative vehicle concepts, efficient prototyping with SLA keeps you ahead in fiercely competitive markets. This guide walks through how SLA empowers precision, speed, and design flexibility so your prototypes move from concept to functional reality without delays.

| Point | Details |

|---|---|

| Stereolithography (SLA) Benefits | SLA enables rapid prototyping with exceptional accuracy and surface finish, greatly enhancing product development cycles. |

| Variants and Cost Considerations | The choice between top-down and bottom-up SLA systems affects cost, size, and operational characteristics. |

| Applications in Industries | SLA technology is widely adopted in aerospace and automotive sectors for producing complex components and lightweight prototypes. |

| Comparative Advantages over Traditional Methods | SLA's additive manufacturing technique allows for greater geometric complexity and minimal material waste compared to subtractive techniques. |

Stereolithography (SLA) represents a revolutionary additive manufacturing technology that transforms liquid photopolymer resins into precise three-dimensional objects through selective laser curing. This advanced prototyping method enables rapid product iteration by converting digital design blueprints into tangible prototypes with exceptional accuracy and surface detail.

The core principles of SLA fundamentally revolve around network analysis in complex systems, where intricate interactions between design parameters, material properties, and laser processing techniques determine the final prototype's quality. Engineers leverage sophisticated computational models to predict and optimise prototype outcomes, ensuring consistent performance across various manufacturing scenarios.

Key characteristics that distinguish SLA from traditional manufacturing methods include:

Within industrial prototyping contexts, SLA technology provides manufacturers unprecedented flexibility in transforming conceptual designs into functional prototypes. By understanding material behaviour, laser interactions, and computational modelling techniques, engineers can systematically control every aspect of the prototype fabrication process.

Pro tip:Calibrate your laser parameters meticulously and select photopolymer resins matched precisely to your specific prototype requirements to maximise dimensional accuracy and mechanical performance.

Stereolithography encompasses multiple architectural approaches that fundamentally transform how photopolymer resins are transformed into precise three-dimensional objects. Stereolithography apparatus (SLA) variants primarily distinguish themselves through two critical configuration methods: top-down and bottom-up printing mechanisms, each presenting unique advantages for different manufacturing requirements.

The two primary SLA variants demonstrate distinct operational characteristics. Top-down SLA systems position the laser above the resin tank, progressively building objects by lowering the build platform into the liquid polymer. Conversely, bottom-up configurations feature an inverted arrangement where the laser cures resin from beneath a transparent build platform, enabling more compact machine designs and potentially lower manufacturing costs.

Here is a comparison of top-down and bottom-up SLA printing mechanisms:

| SLA Variant | Build Platform Position | Typical Machine Size | Relative Manufacturing Cost |

|---|---|---|---|

| Top-down | Above resin tank | Larger footprint | Higher |

| Bottom-up | Below resin tank | More compact | Lower |

Material selection represents another crucial dimension in SLA prototyping, with resin categories encompassing:

Engineers must meticulously evaluate material properties against specific project requirements, considering factors such as tensile strength, elongation, heat resistance, and surface finish. The nuanced selection process demands comprehensive understanding of how different resin compositions interact with laser curing parameters and intended functional applications.

Pro tip: Always conduct preliminary material testing and verify resin compatibility with your specific SLA printer to ensure optimal prototype performance and dimensional accuracy.

Stereolithography has revolutionised manufacturing processes in aerospace and automotive industries by enabling rapid prototyping of complex components. These high-precision sectors leverage SLA technology to dramatically accelerate product development cycles, reduce manufacturing costs, and create intricate geometries that traditional manufacturing methods cannot achieve.

In aerospace engineering, SLA finds critical applications across multiple domains. Manufacturers utilise this technology for producing lightweight aerodynamic prototypes, sophisticated sensor housings, and intricate interior components. Turbine blade mock-ups, aircraft cabin component models, and precision-engineered aerospace instrumentation panels represent prime examples where SLA's exceptional dimensional accuracy proves invaluable.

Automotive applications of SLA encompass a wide range of critical engineering requirements:

The transformative potential of SLA in these industries lies in its ability to bridge conceptual design and functional testing rapidly. Engineers can now iterate designs with unprecedented speed, reducing development timelines from months to mere weeks. By enabling quick, cost-effective prototype creation, SLA empowers automotive and aerospace designers to explore more innovative solutions and push technological boundaries.

Pro tip:Select photopolymer resins with mechanical properties closely matching your final production material to ensure the most accurate prototype performance and validation.

Stereolithography presents transformative advantages for product design and testing, offering exceptional process control for intricate prototyping. This advanced manufacturing technique enables designers to rapidly create precise, detailed components that closely represent final product specifications, dramatically reducing traditional development bottlenecks.

The precision of SLA technology allows engineers to validate design concepts with unprecedented accuracy. By producing high-fidelity prototypes that capture minute geometric details and surface characteristics, design teams can conduct comprehensive functional testing early in the development cycle. This early validation mechanism helps identify potential design flaws, structural weaknesses, and performance limitations before significant resources are invested in full-scale production.

Key benefits of SLA in product design and testing include:

The technology's ability to support iterative design processes transforms how engineering teams approach product development. By reducing the time and cost associated with traditional prototyping, SLA empowers designers to explore more innovative solutions, experiment with advanced geometries, and make data-driven design decisions with greater confidence and speed.

The following table summarises how SLA technology impacts key aspects of the prototyping process:

| Aspect | SLA Capability | Business Benefit |

|---|---|---|

| Iterative Design | Rapid prototype turnaround | Faster time-to-market |

| Surface Accuracy | High geometric precision | Reduces need for extensive finishing |

| Material Versatility | Wide resin material selection | Greater design flexibility |

| Complexity Handling | Easily produces intricate shapes | Enables innovative product features |

Pro tip:Invest in high-resolution SLA equipment and calibrate your printing parameters meticulously to ensure consistent prototype quality across different design iterations.

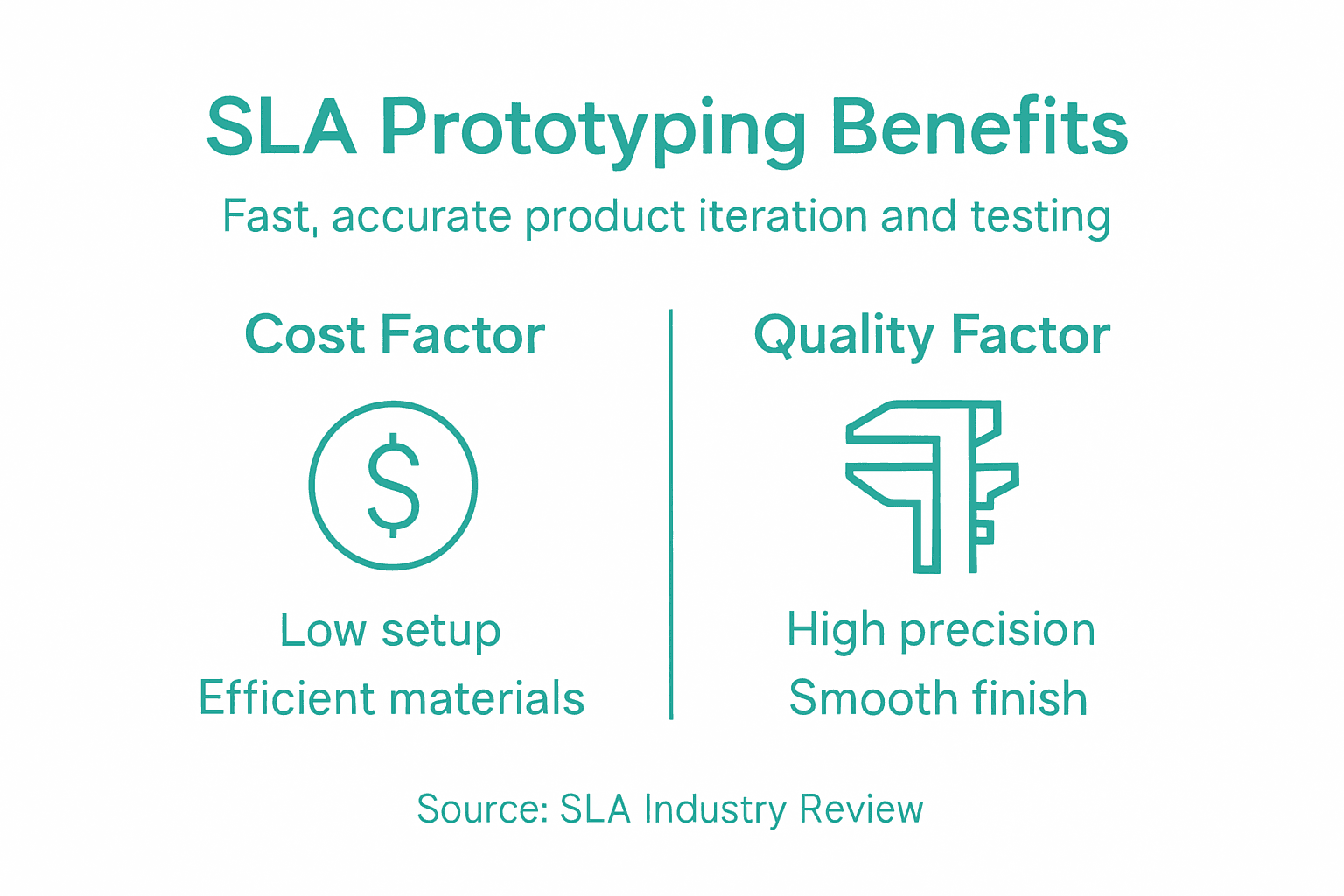

Stereolithography represents a nuanced manufacturing technology that balances critical performance and economic parameters. This advanced prototyping method offers manufacturers a sophisticated approach to managing development costs, production speed, and final product quality through intelligent technological design and material selection.

The economic landscape of SLA technology reveals complex trade-offs between initial investment and long-term efficiency. While photopolymer resins typically command higher material costs compared to traditional manufacturing methods, the overall economic advantage emerges through dramatically reduced labor expenses and accelerated design iteration cycles. Engineers can rapidly prototype multiple design variations, substantially minimising potential downstream production risks and associated financial expenditures.

Key comparative considerations for SLA include:

Comparing SLA with alternative manufacturing techniques demonstrates its unique positioning. Unlike traditional methods, SLA enables precise geometric reproduction with minimal material waste, offering superior dimensional accuracy and surface quality. The technology's ability to produce complex, intricate components rapidly makes it particularly valuable for industries demanding high-precision engineering solutions.

Pro tip: Conduct a comprehensive cost-benefit analysis considering not just material expenses, but total development cycle time and potential design iteration savings when evaluating SLA for your prototyping requirements.

Stereolithography represents a revolutionary leap beyond traditional prototyping methodologies, offering unprecedented precision and efficiency in product development. Rapid prototyping techniques fundamentally transform how engineers conceptualise, design, and validate product iterations compared to conventional manufacturing approaches.

Traditional prototyping methods like CNC machining and injection moulding rely on subtractive manufacturing techniques, where material is systematically removed to create desired shapes. In contrast, SLA employs an additive approach, building components layer by layer using photopolymer resins and laser technology. This fundamental difference enables SLA to produce significantly more complex geometries with minimal material wastage, dramatically reducing both production time and associated manufacturing expenses.

Key distinctions between SLA and traditional prototyping include:

The transformative potential of SLA becomes particularly evident when examining intricate design requirements. Where traditional methods might struggle with complex internal structures or minute geometric details, SLA can effortlessly reproduce sophisticated designs with micrometre-level precision. This capability makes SLA especially valuable in industries demanding high-performance, intricately designed components such as aerospace, medical device manufacturing, and advanced engineering sectors.

Pro tip: Evaluate your specific design requirements holistically, considering not just immediate prototyping needs but long-term development goals when selecting between SLA and traditional prototyping methodologies.

SLA 3D printing plays a critical role in driving rapid product iteration by enabling engineers and designers to produce highly detailed prototypes with smooth surface finishes and tight dimensional accuracy. China has emerged as a leading hub for SLA prototyping thanks to its large-scale additive manufacturing facilities, broad resin material availability, and skilled technical teams. With advanced SLA printer fleets and streamlined production workflows, Chinese manufacturers can deliver high-quality prototypes in short lead times, allowing product teams to test designs, validate functionality, and refine features more frequently during development.

In addition to speed and precision, sourcing SLA prototyping from China offers significant cost advantages without sacrificing quality. Competitive pricing, fast quoting systems, and integrated post-processing services—such as curing, sanding, painting, and assembly—enable companies to receive production-quality prototypes at lower overall costs. This combination of affordability, rapid turnaround, and engineering expertise makes China an ideal partner for businesses seeking to accelerate product iteration and shorten time-to-market through SLA-based prototyping.

The article highlights key challenges faced during rapid product iteration such as balancing precision, material versatility, and production speed in SLA prototyping. If you need to overcome bottlenecks like lengthy design cycles or inconsistent prototype quality, mastering laser calibration, resin selection, and dimensional accuracy is essential. These pain points resonate deeply with engineers and designers aiming to transform complex digital concepts into functional, market-ready prototypes swiftly.

At WJ Prototypes, we specialise in delivering high-quality SLA prototyping services that tackle these exact challenges. Our advanced additive manufacturing technologies ensure exceptional geometric precision and superior surface finish while supporting a wide range of materials including engineering-grade and speciality resins. Whether your project demands aerospace-grade accuracy or automotive complexity, our ISO certified manufacturing and quick turnaround times empower you to prototype and iterate faster than ever.

Discover how our comprehensive solutions can elevate your prototyping process from concept to reality with WJ Prototypes. Explore our full range of services including SLA rapid prototyping and precision CNC machining designed to meet your toughest design requirements. Don’t let prototyping delays slow your innovation; start your project today and experience the true potential of rapid product iteration.

Stereolithography (SLA) is an advanced additive manufacturing technology that creates precise three-dimensional objects by selectively curing liquid photopolymer resins using a laser.

SLA offers exceptional geometric precision, superior surface finish, the ability to produce complex internal geometries, and rapid production cycles, all of which enable faster product development and iteration.

Unlike traditional subtractive methods, SLA employs an additive approach, allowing for more complex geometries with minimal material waste, significantly faster production times, and higher dimensional accuracy.

SLA technology supports various resin categories, including standard resins for basic prototyping, engineering-grade materials, biocompatible formulations, high-temperature resistant polymers, and flexible compounds, allowing for tailored solutions based on project needs.

Role of Prototyping in Product Development: Complete Guide

Rapid Prototyping Guide | 5 Important Steps To Prototype Design & Manufacturing

A Comprehensive Guide To Prototyping in Product Design

Fast Prototyping Turnaround in China | Speed Up Product Development

How to Shorten Sales Cycles for Rapid Growth - Ahead of Sales