- Room 1807, Unit 9, Building 2, Shangxing Commercial Street, Shangde Road, Shangxing Community, Xinqiao Subdistrict, Bao'an District, Shenzhen City, China

Aerospace & UAV

WJ Prototypes is your 3D manufacturing partner from prototype to large scale production.

Consumer Electronics

New Product Introduction Solutions for Consumer Electronics.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Automotive

New Product Introduction Solutions for Automotive

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

Every aerospace or automotive project faces a pivotal decision point when design ideas look promising on screen but doubts linger about real-world performance. Misconceptions about what prototyping can truly accomplish often stall this crucial process, leading to misaligned expectations and costly delays. As rapid prototyping becomes central to reducing time to market, understanding its actual role and addressing industry myths is now vital for managers aiming to achieve both speed and precision. Prototyping alignment between engineering and design teams is the foundation of smarter, cost-effective product development.

| Point | Details |

|---|---|

| Early Prototyping is Critical | Initiating prototyping early helps identify design uncertainties and validates concepts before major resources are committed, ultimately saving costs. |

| Align Stakeholder Objectives | Ensuring all stakeholders understand the prototype's purpose mitigates misalignment, prevents duplicated efforts, and keeps costs in check. |

| Choose the Right Prototyping Method | Selecting appropriate fidelity levels based on development stage optimises cost-effectiveness and insight gained from each prototype iteration. |

| Iterative Processes Enhance Learning | Adopting iterative prototyping facilitates rapid feedback, allowing teams to avoid costly redesigns by uncovering critical issues early. |

Prototyping is fundamentally the process of creating a preliminary version of a product to test concepts, validate design decisions, and gather feedback before committing to full-scale production. It's far more than simply building a quick mock-up. A prototype serves multiple purposes depending on the development stage: it can evaluate technical feasibility, assess user experience, prove a design concept works, or demonstrate market viability. The diversity of prototyping approaches means that manufacturing organisations often use different types simultaneously. Some organisations employ low-fidelity prototypes early (think cardboard models or 3D-printed visual mockups), whilst others jump directly to high-fidelity prototypes that function like final products. This flexibility is precisely why prototyping has become indispensable across aerospace, automotive, and medical device sectors globally.

However, significant misconceptions plague the manufacturing industry about what prototyping actually accomplishes and how it should be deployed. Research into prototyping practice in industrial settings reveals that teams often hold conflicting expectations about prototyping's purpose, with engineering, design, and client perspectives frequently misaligned. One widespread myth is that prototyping is expensive and time-consuming, when in reality it prevents far costlier mistakes downstream. Another misconception treats prototyping as optional, something you do if you have budget left over. In truth, organisations without mature prototyping practices struggle with longer development cycles, higher material waste, and costly design revisions after tooling has been commissioned. The gap between how prototyping should function and how organisations actually deploy it creates friction that delays products and inflates expenses.

Understanding prototyping's role in product development requires acknowledging that different stakeholders need different things from a prototype. Manufacturing engineers care about whether tolerances are achievable and whether assembly sequences work. Product managers need evidence that the design addresses market needs. Quality assurance teams want to identify potential failure modes. Designers want to confirm that their vision translates to physical reality. When organisations fail to align these perspectives upfront, they waste resources creating prototypes that answer the wrong questions. The most effective prototyping strategies begin by explicitly defining what each prototype must prove and who needs that proof. This clarity transforms prototyping from an afterthought into a strategic tool that compresses development timelines and reduces material waste by 40-60% on average.

Pro tip: Before commissioning any prototype, gather your full team and document specifically what questions the prototype must answer and which stakeholders need those answers resolved, preventing costly misalignment and rework later.

Manufacturing organisations don't have a one-size-fits-all approach to prototyping. The choice of prototyping method depends entirely on your development stage, budget constraints, and what questions you need answered. Broadly speaking, prototypes fall into three categories: physical prototypes that replicate both appearance and functionality; sketches and diagrams for early conceptual communication; and digital or computational models that simulate behaviour and performance without building anything tangible. Early-stage product development often benefits from sketches and simple conceptual models, whilst later stages demand physical validation. The challenge lies in selecting the right mix. Some aerospace and automotive teams use all three simultaneously—digital simulations running in parallel with physical builds to compress timelines whilst maintaining design rigour.

Physical prototypes remain the gold standard for design validation, particularly when stakeholders need to assess ergonomics, assembly feasibility, or user interaction. Modern manufacturing enables rapid creation of physical prototypes through various technologies. CNC machining produces precisely machined metal or plastic parts that match production specifications. Injection moulding creates multiple identical parts quickly, ideal for testing assembly sequences and volume production scenarios. 3D printing technologies like SLA, SLS, and MJF generate complex geometries that would be prohibitively expensive to machine, particularly for intricate internal features. Vacuum casting bridges the gap between low-volume hand-made prototypes and high-volume injection moulding. Sheet metal fabrication handles flat-pack assemblies and structural components. The critical insight here is that contemporary prototyping methods each excel at different validation tasks—physical prototypes generally outperform digital-only approaches when communication and design feedback matter most.

Digital prototypes offer speed and cost advantages, particularly in early stages. CAD models allow engineers to identify geometric clashes, calculate structural loads, and simulate thermal behaviour before any material is ordered. Computational models predict performance characteristics like fatigue life or fluid dynamics. Virtual and augmented reality prototypes let teams visualise scale and spatial relationships without manufacturing. However, digital prototypes cannot fully replace physical validation. You cannot assess surface finish quality, vibration characteristics, or manufacturing-induced defects from a simulation. The most cost-effective strategy combines both: use digital prototypes to eliminate obvious design flaws, then create focused physical prototypes that answer the remaining questions. This parallel approach, common in aerospace and automotive development, reduces the total number of physical iterations needed whilst catching problems early when corrections are inexpensive.

The following table compares physical and digital prototyping methods, highlighting their main strengths and limitations:

| Method | Key Advantage | Main Limitation | Typical Use Case |

|---|---|---|---|

| Physical Prototypes | Realistic validation, tangible proof | Expensive, slower iteration | Final design confirmation |

| Digital Prototypes | Rapid, low-cost iteration | Misses real-world defects | Early-stage error detection |

| Hybrid Approach | Balances speed and accuracy | Coordination and resource planning | Complex product development cycles |

Pro tip: Match your prototyping technology to your specific validation need—use digital models to explore design space quickly and affordably, then commit to physical prototypes only for the questions that require real-world testing, maximising insight whilst minimising waste.

The financial case for prototyping rests on a straightforward economic principle: catching mistakes early costs far less than fixing them late. When a design flaw escapes to production tooling, you face catastrophic expenses. Retooling a stamping die for automotive body panels can cost £50,000 to £200,000 and consume months. Discovering that same flaw during prototyping costs a fraction of that, perhaps a few thousand pounds and a week's delay. Prototyping's role in risk mitigation centres on shifting design validation from the factory floor to the development lab, where changes are trivial. Every prototype iteration that prevents a single tooling restart pays for itself many times over. Aerospace teams know this intimately—they prototype extensively not because they have unlimited budgets, but because they cannot afford a field failure that grounds aircraft or triggers recalls. The same logic applies across automotive, medical devices, and industrial machinery.

Prototyping eliminates uncertainty by generating genuine design information before committing capital to production infrastructure. Early-stage prototypes answer fundamental questions: Does this design approach work? Can we manufacture it with acceptable tolerances? Will assembly sequences function as intended? Does the product meet user expectations? Economic analysis of prototyping trade-offs reveals that prototypes of varying fidelities deliver valuable insights at proportionally different costs, allowing teams to make targeted investments in design knowledge. You do not need high-fidelity prototypes for every question. A low-cost 3D-printed mockup might prove enough to validate ergonomics. A digitally simulated assembly sequence might eliminate obvious design clashes. A focused physical prototype tests only the critical performance question remaining. This layered approach compresses spending by concentrating resources on questions that actually matter. Teams that skip prototyping typically conduct these validation experiments after full production tooling is commissioned, when changes cost 10 to 100 times more.

Iterative prototyping also prevents costly late-stage redesigns by building team alignment around a shared physical reality. Engineers, designers, and manufacturing specialists often hold conflicting assumptions about what a design requires. Those assumptions collide when the first production parts arrive and do not meet specifications. Prototyping exposes these disconnects while solutions remain inexpensive. A production manager might identify an assembly sequence that requires £2 million in equipment investment. A designer might propose a material change that eliminates that cost but requires tooling modification. A prototype makes this trade-off visible before anyone commits to either path. Stakeholder engagement through physical prototyping accelerates timelines and improves decision quality because everyone operates from the same evidence rather than competing theories.

Pro tip: Schedule prototyping validation for your three or four highest-risk assumptions rather than prototyping exhaustively—this focused approach identifies deal-breaking issues whilst preserving budget for manufacturing scale-up.

Organisations that fail to realise cost savings from prototyping typically fall into predictable traps. The most damaging pitfall is commencing production tooling without resolving fundamental design uncertainties. Teams convince themselves that prototyping will delay market entry, so they skip validation and push directly to manufacturing. Then reality strikes: the first production run reveals tolerance issues, assembly problems, or performance shortfalls. Suddenly you are redesigning under crisis conditions, retooling under deadline pressure, and burning through contingency budget. What should have cost a few thousand pounds in prototype iterations now costs hundreds of thousands in scrap, rework, and expedited tooling. Common prototyping pitfalls include prematurely settling on the first apparently viable idea, becoming emotionally attached to designs that should be abandoned, and wasting resources on low-value prototyping questions. Teams also sometimes prototype without establishing clear success criteria, meaning they generate data but cannot decide what it means.

Another significant cost driver emerges from misaligned stakeholder expectations. Industrial prototyping research consistently shows that engineering, design, and manufacturing teams often hold conflicting views about what a prototype should accomplish. Engineers want to validate performance characteristics. Designers want to assess aesthetics and user interaction. Manufacturing specialists want to confirm producibility and identify tooling requirements. Product managers want evidence of market viability. When these perspectives are not reconciled before prototyping begins, teams build multiple prototypes answering different unstated questions, duplication that balloons costs unnecessarily. A stamping engineer in an automotive programme might prototype to verify press tonnage requirements whilst a design team simultaneously prototypes identical geometry to assess surface finish appearance. Organisational immaturity in prototyping practices exacerbates this waste. Teams lacking a defined prototyping strategy create ad-hoc prototypes reactively, often after discovering problems they could have anticipated.

Prototyping also becomes expensive when teams lack discipline around prototype scope and iteration limits. Building perfect prototypes consumes resources that should remain available for iteration. A 3D-printed part that takes six weeks to perfect is less valuable than three rough iterations produced in three weeks, because rapid feedback accelerates learning. Teams sometimes fall into the trap of treating early prototypes like production parts, adding unnecessary finishing, assembly complexity, or feature completeness. This mindset transforms what should be quick validation experiments into elaborate projects. Another hidden cost driver is discouragement from prototype failures. When a prototype demonstrates a concept does not work, some teams interpret this as wasted effort rather than valuable information that prevented a costlier mistake. This psychological barrier prevents teams from embracing the iterative cycle that actually reveals design truth.

Here is a summary of common pitfalls in prototyping and recommended mitigation strategies:

| Pitfall | Consequence | Mitigation Strategy |

|---|---|---|

| Skipping prototyping to save time | Late-stage, costly redesigns | Validate critical assumptions early |

| Undefined success criteria | Wasted resources and ambiguity | Set clear objectives per prototype |

| Over-investing in single prototype | Loss of budget flexibility | Favour multiple rapid iterations |

| Misaligned stakeholder expectations | Duplicate effort, higher costs | Align requirements before building |

| Treating prototypes as final products | Unnecessary complexity and delays | Use appropriate fidelity per stage |

Pro tip: Define prototyping success criteria and stakeholder requirements in writing before building anything, then limit each prototype iteration to answering one or two specific questions rather than trying to validate everything simultaneously.

Cost-effective prototyping demands a deliberate strategy rather than reactive improvisation. The foundation is starting prototyping early, before design concepts have calcified into assumed requirements. Teams that delay prototyping until designs feel complete waste money validating decisions already locked in place. Early prototypes explore multiple design directions simultaneously, identifying the most promising path before committing resources to detailed development. This front-loading of validation compresses overall timelines and prevents the costly dead ends that emerge when prototyping occurs after major decisions are finalised. Another cornerstone practice is defining clear prototyping objectives upfront. Before commissioning any prototype, document precisely what question it must answer and which stakeholder needs that answer. A prototype answering the wrong question wastes budget regardless of how cheaply it was manufactured. Paired with this is selecting appropriate fidelity levels. Low-fidelity prototypes like cardboard mockups, sketches, or rough 3D prints answer conceptual questions at minimal cost. Medium-fidelity prototypes like CNC-machined samples validate manufacturing feasibility. High-fidelity prototypes matching production specifications answer final validation questions. Matching fidelity to the specific question prevents over-engineering early iterations.

Prototyping strategies for cost reduction and time savings emphasise the importance of iterative testing cycles and integrating digital tools alongside physical prototypes. Rather than building one elaborate prototype and testing it, effective teams create rapid sequences of simple prototypes, each revealing one or two insights that inform the next iteration. Digital simulation and CAD analysis eliminate obvious flaws before physical prototyping begins, reducing the number of physical iterations required. Aerospace teams commonly run computational fluid dynamics simulations to eliminate poor aerodynamic concepts, then prototype only the most promising candidates physically. This parallel approach of digital pre-screening and physical validation compresses both cost and schedule. Involving stakeholders throughout prototyping rather than at the end prevents the costly discovery that different team members wanted different validation outcomes. Manufacturing engineers, designers, product managers, and quality specialists should see prototypes during development, not just upon completion.

Practical implementation also requires discipline around managing prototype scope and production partnerships. Many organisations fail to realise cost savings because they treat each prototype as a mini-production project, adding unnecessary finishing, quality control, or perfectionism. Contextual factors influencing prototyping strategy highlight that selecting manufacturing partners experienced in rapid prototyping yields significant cost advantages. Rapid prototyping specialists understand how to deliver functional validation quickly and cost-effectively, avoiding the overhead and lead times associated with traditional production suppliers. A Chinese rapid prototyping partner, for instance, can produce iterative 3D-printed samples in days rather than weeks, enabling multiple validation cycles within the timeline a traditional supplier requires for a single prototype. Documenting lessons from each prototype creates organisational knowledge that compounds savings across multiple projects. Teams repeating prototyping mistakes across successive products waste accumulated capital that could have been prevented through systematic learning.

Pro tip: Establish a prototyping decision matrix before starting any project that documents what questions each prototype must answer, acceptable fidelity levels for each stage, and maximum budget per iteration, preventing scope creep and keeping teams focused on cost-effective validation.

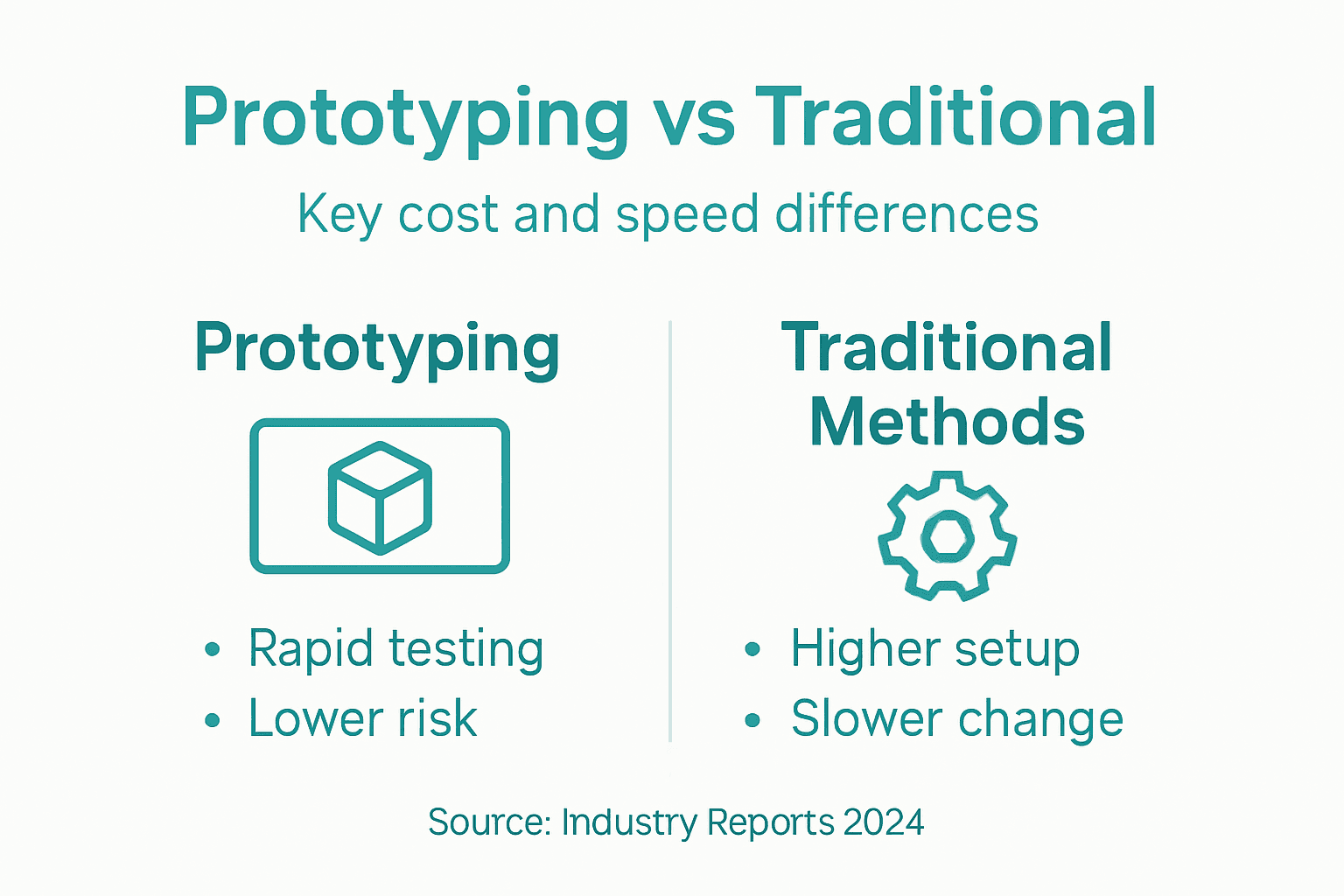

Traditional manufacturing methods like machining, stamping, and casting were historically the only option for product validation. A team needing to test a concept would commission a custom die for injection moulding or have machinists hand-craft a sample. Lead times stretched into months. Costs ran into tens of thousands of pounds. If the prototype revealed design flaws, you faced a choice between accepting the compromised design or repeating the entire expensive process. This reality created a powerful incentive to over-engineer designs upfront, avoiding the need for physical validation altogether. Teams would spend months perfecting CAD models, attempting to eliminate all uncertainty through simulation alone, because commissioning a physical prototype felt prohibitively risky. The result was designs that looked good on screen but encountered unexpected problems during production tooling.

Modern rapid prototyping technologies have fundamentally altered this equation. Additive manufacturing processes like 3D printing, vacuum casting, and sintering enable teams to create functional prototypes in days rather than months and at a fraction of traditional costs. Additive manufacturing compared with traditional methods reveals that whilst additive manufacturing excels at design complexity and iteration speed, it does not universally replace traditional techniques. Additive processes struggle with high-volume production speed, surface finish precision, and material properties matching traditional methods. The crucial insight is that prototyping and production manufacturing serve different objectives. You might prototype a complex aerospace bracket using 3D printing because it accommodates intricate internal geometry and validates assembly fit quickly. For production, you would transition to CNC machining or casting because those methods deliver superior material properties and surface quality at volume. Traditional methods remain optimal for high-volume, high-speed production. Rapid prototyping methods optimise for design validation, low-volume precision, and schedule compression.

The real cost advantage emerges when organisations blend both approaches strategically. Contemporary prototyping methods demonstrate that physical prototypes outperform purely digital approaches when communication and decision-making matter most. Physical 3D-printed prototypes enable engineers, designers, and stakeholders to hold something tangible, identify real-world issues that simulations missed, and make informed decisions collaboratively. A digital model might show that parts fit geometrically. A physical prototype reveals whether tolerances accommodate assembly in actual manufacturing conditions or whether thermal stress causes unexpected deflection. Teams save the most money by using rapid prototyping early to validate the critical design questions, then transitioning to traditional manufacturing methods optimised for production volume and quality. This two-phase approach compresses development timelines, reduces design uncertainty before tooling investment, and eliminates the costly surprises that plague programmes relying exclusively on simulation or traditional validation methods. The aerospace and automotive sectors have embraced this hybrid model systematically because it delivers both speed and cost savings.

Pro tip: Plan your manufacturing strategy in two phases: use rapid prototyping to validate design uncertainty and manufacturing feasibility at minimal cost, then transition to traditional production methods only after prototyping confirms the design is production-ready, avoiding expensive tooling mistakes.

Manufacturers face the critical challenge of reducing costly late-stage redesigns and minimising risks during product development. This article highlights common pitfalls such as misaligned stakeholder expectations, undefined prototype goals, and over-investment in single iterations. If your team struggles with balancing speed, cost, and accuracy in prototyping, adopting a clear and focused prototyping strategy is essential. Concepts like matching prototype fidelity to validation needs and integrating both digital and physical methods can transform prototyping into a powerful tool that compresses timelines and cuts wastage by up to 60 percent.

At WJ Prototypes, we specialise in delivering precisely this balance. Our comprehensive rapid prototyping and traditional manufacturing services including SLA, SLS, MJF, CNC machining, and injection moulding are designed to accelerate your product validation while controlling costs. Whether you need quick iterations to confirm core design assumptions or high-fidelity prototypes for final validation, our ISO certified team provides expert guidance to help you define clear objectives and select the optimal technology for each development phase. To experience the benefits of strategic prototyping and avoid expensive production errors, contact WJ Prototypes today. Start your journey to faster, cost-effective product development by requesting an instant quote and consulting with our engineers now.

Prototyping helps identify design flaws and validate functionality early in the development process. This prevents costly mistakes during production, as catching errors in prototypes is significantly cheaper than addressing them after tooling has been commissioned.

By resolving fundamental design uncertainties before entering production, prototyping ensures that all stakeholders are aligned on requirements. This reduces the chances of encountering significant issues during manufacturing, which can lead to costly redesigns and delays.

Manufacturing organisations typically use physical prototypes that replicate both appearance and functionality, sketches and diagrams for early conceptual communication, and digital or computational models that simulate behaviour and performance without tangible production.

Common pitfalls include skipping prototyping to save time, having unclear success criteria, over-investing in a single prototype, and failing to align stakeholder expectations. Each of these can result in duplicate efforts or costly late-stage redesigns.

Guide To Cost-Effective Prototyping - Reducing Risks and Expenses

Why Prototyping in China Drives Down Costs for Manufacturers

A Comprehensive Guide To Prototyping in Product Design

Role of Prototyping in Product Development: Complete Guide

Fabric Cost Estimation Process: Step-by-Step Guide for Projects