- Room 1807, Unit 9, Building 2, Shangxing Commercial Street, Shangde Road, Shangxing Community, Xinqiao Subdistrict, Bao'an District, Shenzhen City, China

Aerospace & UAV

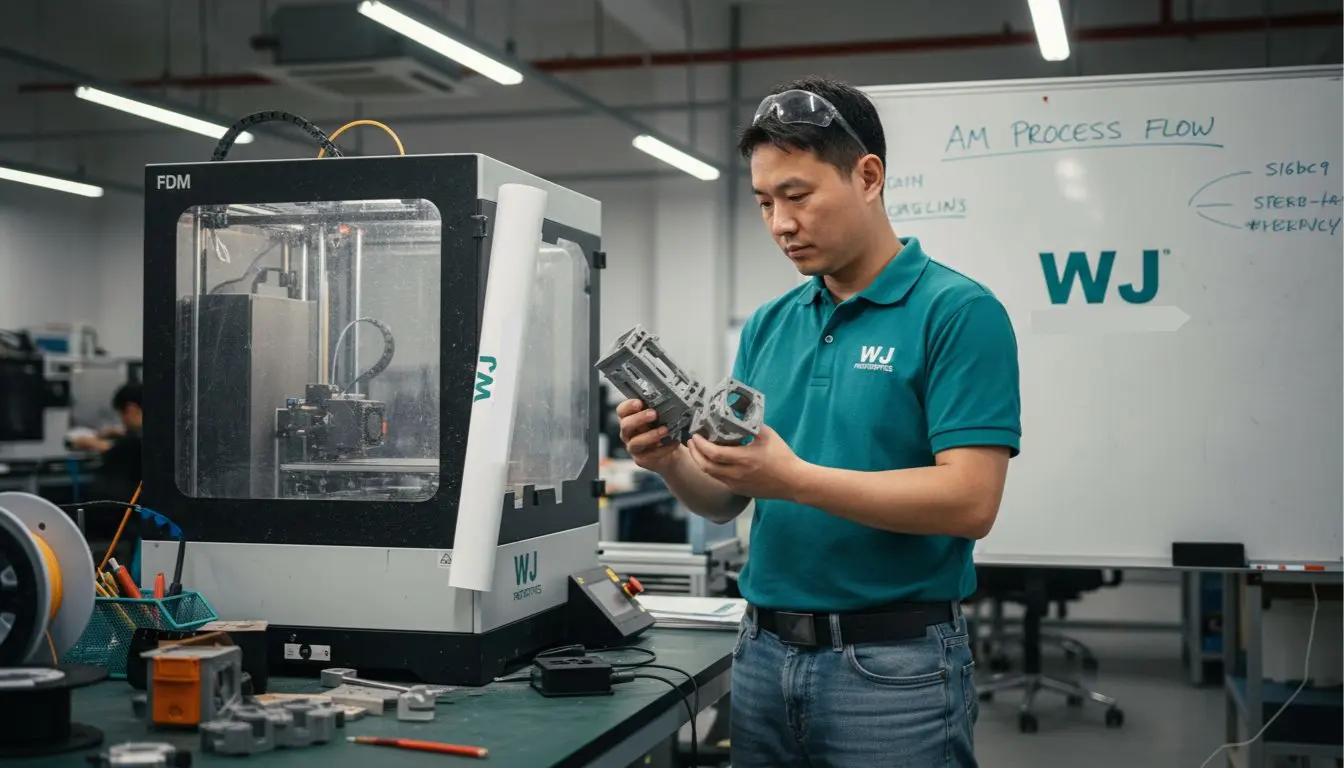

WJ Prototypes is your 3D manufacturing partner from prototype to large scale production.

Consumer Electronics

New Product Introduction Solutions for Consumer Electronics.

Robotics & Automation

Need some assistance bringing your robotic device or parts from the sketch-board to reality?

Medical Devices

The medical industry needs high quality, dependable and safe parts and products.

Automotive

New Product Introduction Solutions for Automotive

Industrial Machinery

The main purpose of industrial prototyping is to take the product from drawings into the real world.

Nearly every engineering team faces a crucial choice when it comes to rapid prototyping. The sheer number of 3D printing technologies available today can be overwhelming, especially when each offers unique advantages for speed, detail, or strength. With over 70% of advanced manufacturing firms in the world adopting additive manufacturing, understanding the right technology for your project can directly impact both timeline and results. This guide demystifies leading options, showcasing exactly how each method serves the needs of innovative engineers.

| Takeaway | Explanation |

|---|---|

| 1. Choose the right technique | Select the optimal additive manufacturing method based on project requirements for performance and characteristics. |

| 2. Understand material properties | Different additive techniques use varied materials, impacting prototype durability and functionality significantly. |

| 3. Optimize process parameters | Tailor settings based on selected materials to ensure accuracy and desired performance in final components. |

| 4. Consider design complexity | Leverage additive manufacturing's ability to create intricate geometries that traditional methods cannot achieve. |

| 5. Evaluate cost-effectiveness | Assess the economic benefits of each additive technique based on project scale and production needs. |

Stereolithography represents a cutting-edge additive manufacturing technique that transforms liquid photopolymer resin into intricate three-dimensional objects using precise laser technology. By enabling the creation of high-precision prototypes with exceptional surface quality, SLA has revolutionised engineering design and rapid prototyping processes.

At its core, SLA technology operates through photopolymerisation a process where ultraviolet laser beams systematically trace and cure liquid resin layers, transforming them into solid geometric structures. This method achieves extraordinary layer thicknesses as minimal as 25 microns, allowing engineers to produce components with remarkable geometric accuracy and intricate surface details.

Practical applications of SLA span multiple industries including medical device manufacturing, automotive design, aerospace engineering, and precision instrumentation. Engineers particularly value SLA for creating complex prototypes that demand superior dimensional accuracy such as intricate mechanical components, architectural models, medical implant prototypes, and microfluidic devices.

Key advantages of SLA include ultra-high resolution, smooth surface finishes, and exceptional dimensional precision. The technology enables rapid production of complex geometries that would be challenging or impossible to manufacture through traditional subtractive methods. Modern SLA techniques like High Area Rapid Printing (HARP) have further enhanced manufacturing capabilities by enabling continuous, high-throughput printing of large objects with minimal structural defects.

When selecting SLA for prototyping, engineers should consider material properties, resolution requirements, and post processing needs. Photopolymer resins come in various formulations optimised for specific applications such as transparent models, flexible prototypes, or heat resistant components. Understanding these material nuances ensures optimal prototype performance and accuracy.

Learn more about SLA 3D Printing Services In China

Selective Laser Sintering represents an advanced additive manufacturing technique that transforms powdered materials into robust three-dimensional components through precise laser technology. SLS printing enables engineers to create functional prototypes and end-use parts with remarkable mechanical properties and design complexity.

The SLS process operates by utilising a high-powered laser to selectively sinter powdered materials such as nylon, systematically fusing powder particles together to construct intricate geometric structures. Unlike traditional manufacturing methods, SLS allows for the production of complex geometries without requiring additional support structures, providing unprecedented design freedom for engineering applications.

Engineers across multiple industries leverage SLS technology for creating strong functional parts with exceptional mechanical characteristics. The technique is particularly valuable in aerospace, automotive, medical device manufacturing, and industrial engineering sectors where components must withstand significant mechanical stress and demonstrate high performance.

Key advantages of SLS technology include:

When implementing SLS for engineering projects, careful material selection and parameter optimization are crucial. Understanding the nuanced relationship between powder characteristics, laser parameters, and thermal dynamics will ensure optimal part performance and dimensional accuracy.

Learn more about SLS 3D Printing Services In China

Multi Jet Fusion represents an innovative additive manufacturing technology that delivers exceptional precision and rapid production capabilities for engineering professionals. Additive manufacturing processes have revolutionised product development by enabling sophisticated manufacturing techniques that transcend traditional production limitations.

The MJF process utilises advanced thermal printing technology where a print head systematically deposits binding agents and energy-absorbing materials across a powdered substrate. This method allows for incredibly precise layer-by-layer construction, producing parts with remarkable dimensional accuracy and mechanical consistency. Unlike traditional manufacturing methods, MJF enables engineers to create complex geometries with superior surface quality and structural integrity.

Key advantages of Multi Jet Fusion include:

Engineering teams across automotive, aerospace, medical device manufacturing, and industrial design sectors are increasingly adopting MJF technology. The technique offers unparalleled flexibility in producing functional prototypes and end-use components with complex internal structures and exceptional mechanical properties.

When implementing MJF for engineering projects, careful material selection and process parameter optimisation are crucial. Understanding the nuanced relationship between thermal energy, binding agent characteristics, and powder substrate will ensure optimal part performance and manufacturing consistency.

Learn more about MJF 3D Printing Services In China

Direct Metal Laser Sintering represents a groundbreaking additive manufacturing technique that enables engineers to transform metal powders into complex three-dimensional components with exceptional precision. Rapid prototyping techniques have revolutionised manufacturing by providing unprecedented design flexibility for metal component production.

The DMLS process operates through a sophisticated mechanism where a high-powered laser systematically fuses metallic powder particles, creating fully dense metal parts layer by layer. Unlike traditional subtractive manufacturing methods, DMLS allows engineers to produce intricate geometries with internal structures that would be impossible to manufacture through conventional machining techniques.

Key advantages of Direct Metal Laser Sintering include:

Engineering teams in aerospace, automotive, medical device manufacturing, and precision engineering increasingly utilise DMLS for producing critical components. The technology enables the creation of lightweight, structurally optimised parts with superior mechanical properties and reduced overall manufacturing time.

Successful implementation of DMLS requires thorough understanding of powder characteristics, laser parameters, and thermal dynamics. Engineers must carefully select appropriate metal alloys and optimise process parameters to ensure exceptional part performance and structural integrity.

Learn more about DMLS 3D Printing Services In China

Fused Deposition Modelling represents the most accessible and widely used additive manufacturing technique for engineers seeking cost-effective prototyping solutions. Rapid prototyping processes have transformed product development by enabling engineers to quickly transform digital designs into physical models.

FDM operates through a straightforward extrusion process where thermoplastic filament is heated and systematically deposited layer by layer, creating three-dimensional objects with remarkable precision. The technology works by heating polymer materials to their melting point and precisely extruding them through a computer-controlled nozzle, building components from the bottom up with exceptional dimensional accuracy.

Key advantages of Fused Deposition Modelling include:

Engineering teams across product design, automotive, aerospace, and medical device sectors utilise FDM for creating functional prototypes, proof of concept models, and preliminary design iterations. The technology enables rapid validation of design concepts without significant financial investment.

Successful implementation of FDM requires understanding material properties, optimal print parameters, and design considerations such as layer resolution, infill density, and support structures. Engineers must carefully select appropriate materials and calibrate printing parameters to achieve desired mechanical and aesthetic characteristics.

Learn more about FDM 3D Printing Services In China

Digital Light Processing represents an advanced additive manufacturing technique that delivers exceptional surface quality and precision for engineering prototypes. By leveraging digital projection technology, additive manufacturing processes enable engineers to create intricate components with remarkable dimensional accuracy.

The DLP process utilises a digital projector screen to cure entire layers of photopolymer resin simultaneously, creating highly detailed parts with smooth surface finishes. Unlike traditional layer-by-layer 3D printing methods, DLP projects entire layer images in a single moment, resulting in significantly faster production times and superior geometric precision.

Key advantages of Digital Light Processing include:

Engineering teams in jewellery design, medical device manufacturing, dental prosthetics, and precision instrumentation leverage DLP technology for creating components requiring extraordinary surface smoothness and geometric complexity. The technique is particularly valuable for producing small, intricate parts with minimal post processing requirements.

Successful implementation of DLP requires careful selection of photopolymer resins, understanding optical curing parameters, and optimising projection settings to achieve desired mechanical and aesthetic characteristics.

Binder Jetting represents an innovative additive manufacturing technique that enables engineers to create complex components using multiple materials with exceptional efficiency. Multi-material printing techniques have revolutionised manufacturing by providing unprecedented design flexibility and material diversity.

The Binder Jetting process operates by systematically depositing liquid binding agents onto powdered material layers, creating intricate three-dimensional structures without requiring high temperature thermal processing. Unlike traditional manufacturing methods, this technique allows for the simultaneous integration of different material properties within a single component, enabling engineers to design parts with customised mechanical characteristics.

Key advantages of Binder Jetting include:

Engineering teams in automotive, aerospace, architectural modelling, and industrial design leverage Binder Jetting for creating complex prototypes and functional components. The technology is particularly valuable for producing architectural models, intricate mechanical parts, and customised tooling with embedded functional variations.

Successful implementation requires thorough understanding of powder characteristics, binding agent properties, and thermal curing mechanisms. Engineers must carefully select appropriate materials and optimise printing parameters to achieve desired structural integrity and functional performance.

Below is a comprehensive table summarising the key additive manufacturing techniques and their advantages discussed throughout the article.

| Technique | Key Process | Advantages |

|---|---|---|

| Stereolithography (SLA) | Utilises photopolymerisation to cure resin with lasers. | Ultra-high resolution, smooth finishes, dimensional precision. |

| Selective Laser Sintering (SLS) | Sintering powdered materials using laser. | Mechanical strength, design complexity, material versatility, cost efficiency. |

| Multi Jet Fusion (MJF) | Deposits binding agents across powdered substrate. | Rapid production, high dimensional accuracy, superior surface finish, material efficiency. |

| Direct Metal Laser Sintering (DMLS) | Fuses metallic powders with a high-powered laser. | Complex geometries, material versatility, high precision, reduced material waste. |

| Fused Deposition Modelling (FDM) | Extrudes heated thermoplastic filament layer by layer. | Low cost, material versatility, quick prototyping, easy operation. |

| Digital Light Processing (DLP) | Cures entire layers with digital light projection. | Exceptional surface quality, rapid production speeds, high resolution, material versatility. |

| Binder Jetting | Deposits liquid binding agents on powdered materials. | Material diversity, colour capabilities, low processing temperatures, minimal post processing. |

Engineers face the challenge of balancing complex design requirements with the need for rapid, cost-effective production. Whether you require ultra-high resolution from technologies like Stereolithography or the mechanical strength delivered by Selective Laser Sintering and Direct Metal Laser Sintering, mastering the nuances of additive manufacturing is crucial. Understanding material properties, process parameters, and finishing options can be overwhelming while trying to meet tight deadlines.

At WJ Prototypes, we specialise in turning these challenges into opportunities. Our broad range of services includes SLA, SLS, MJF, DMLS, and traditional fabrication methods tailored to your project needs. Benefit from our expertise in delivering precise prototypes and functional parts with accelerated turnaround times. Explore further how our advanced rapid prototyping and custom manufacturing capabilities can propel your engineering projects from concept to market-ready solutions with confidence and efficiency.

Take the next step today to experience additive manufacturing excellence. Visit WJ Prototypes and get an instant quote to bring your innovative designs to life without compromise.

Stereolithography (SLA) offers ultra-high resolution, smooth surface finishes, and exceptional dimensional precision. By utilising SLA, engineers can produce intricate prototypes rapidly, meeting the demands of projects that require high levels of detail and accuracy.

Selective Laser Sintering (SLS) provides mechanical strength comparable to injection-moulded components while allowing for complex designs without the need for extra support structures. This enhances design freedom for engineers, especially in sectors where durability is essential, such as automotive and aerospace applications.

When using Multi Jet Fusion (MJF), engineers should focus on material selection and process parameters to optimise performance. Achieving high dimensional accuracy within tight tolerances requires a thorough understanding of the characteristics of the powder and binding agents involved in the MJF process.

Direct Metal Laser Sintering (DMLS) enables engineers to produce complex, lightweight parts with superior mechanical properties through efficient use of metal powders. By optimising metal alloy selection and laser parameters, teams can reduce material waste and enhance structural integrity in their designs.

When choosing Fused Deposition Modelling (FDM) as a prototyping method, consider the required material properties, layer resolution, and infill density of the prototypes being created. By calibrating printing parameters effectively, engineers can achieve desired mechanical and aesthetic characteristics in their models.

Digital Light Processing (DLP) excels at producing parts with mirror-like finishes and intricate details due to its ability to cure entire layers simultaneously. Engineers can achieve high-resolution components quickly, making DLP an ideal choice for applications that demand fine surface finishes, such as in jewellery design or dental prosthetics.

Additive Manufacturing Processes and Applications Explained

Additive Manufacturing Guide for Precision Prototyping

Advantages and Disadvantages of 3D Printing - Pros & Cons

Additive Manufacturing Workflow for Prototyping Success

Diesel Injection System Types: Comprehensive Guide for 2025